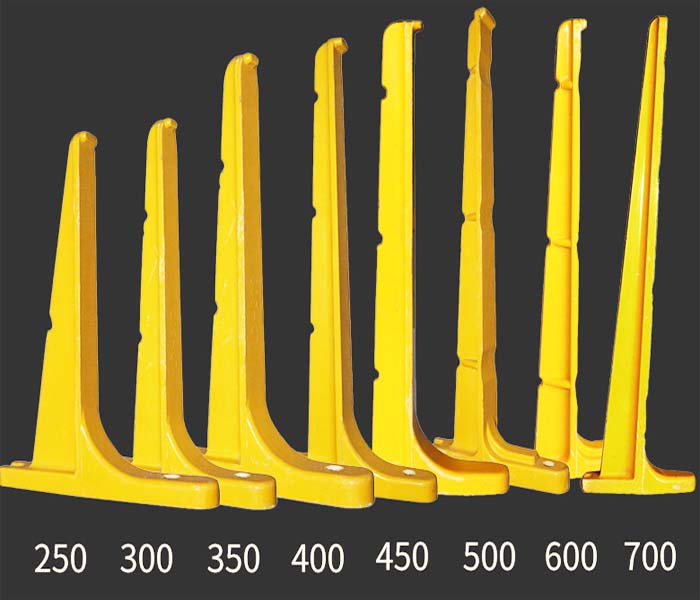

Fiberglass cable mold production cable brackets,the new glass fiber reinforced plastic cable bracket mold production cable bracket adopts the SMC compression molding production process. The full name of SMC in English is Sheet Mould Compound. It is a sheet-like unsaturated polyester reinforced molding compound made of resin paste impregnated glass fiber. It is GF (glass fiber), UP (unsaturated resin), MD (filler) and low Shrinkage additive Sheet molding compound composed of various additives. SMC fiberglass cable support is a thermoset composite material. It is made of SMC composite material pressed at high temperature. The R2O content of the selected alkali-free glass fiber is less than 0.8, which is an aluminoborosilicate component. Its chemical stability, electrical insulating properties and strength are very good, and it is mainly used as electrical insulating material and reinforcing material of FRP.

Producing fiberglass cable molds and cable brackets involves several steps, from design and mold creation to the actual manufacturing process. Here’s a general overview of the process:

Table of Contents

ToggleFiberglass cable mold production cable brackets

1. Design of fiberglass cable mold

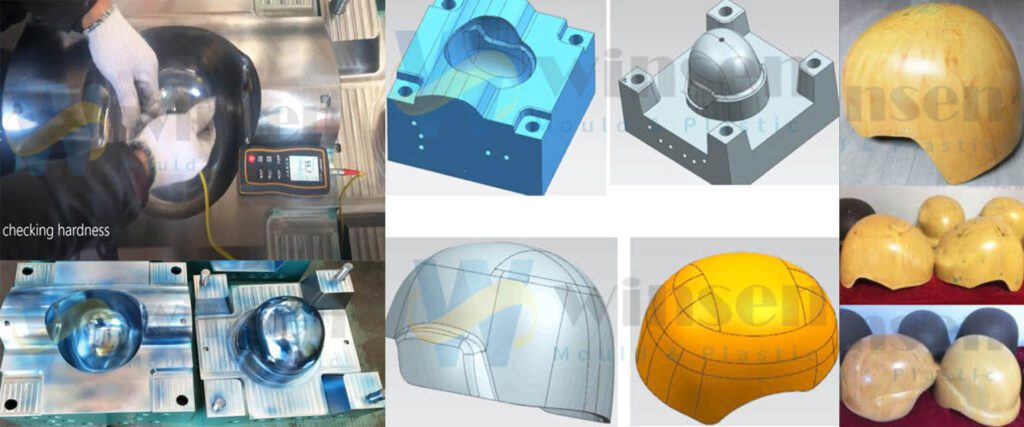

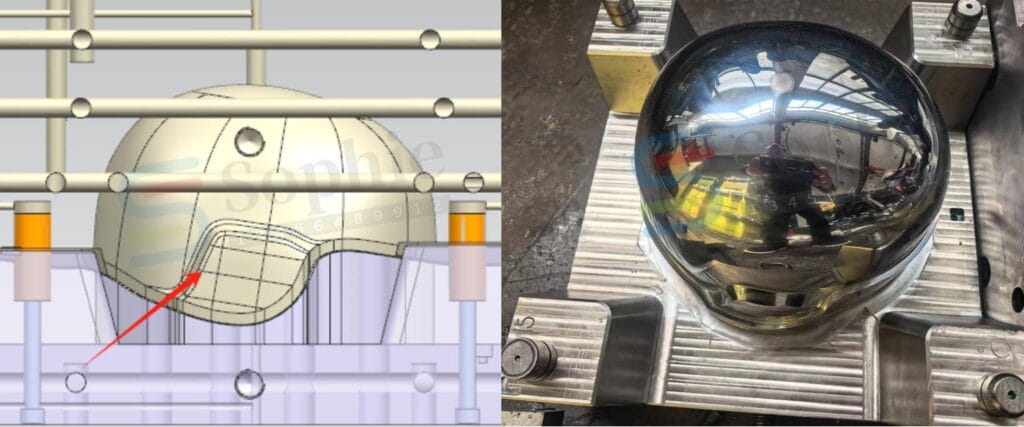

First, it needs a design for your fiberglass cable molds and cable brackets. This design should include specifications for the size, shape, and functionality of the molds and brackets. You can use CAD (Computer-Aided Design) software to create detailed 3D models.

2. Material Selection of cable bracket

Select the appropriate type of fiberglass and resin for your application. Fiberglass composites can vary in terms of strength, flexibility, and resistance to environmental factors, so choose materials that meet your specific requirements.

3. Cable bracket mold making

Making cable bracket molds for both the cable molds and cable brackets. The molds can be made from various materials, but typically they are made from metal or plastic. CNC machining or other precision manufacturing methods can be used to create the molds according to your design specifications.

4. Gel Coat Application

Before applying the fiberglass composite material, a gel coat layer is often applied to the mold’s surface. The gel coat provides a smooth finish and helps protect the mold from damage during the manufacturing process.

5. Layup Process

This step involves layering the fiberglass composite material (consisting of fiberglass sheets and resin) onto the mold’s surface. The layers are built up one by one until the desired thickness is achieved. It’s important to ensure that the layers are properly aligned and compacted to avoid air bubbles or voids.

6. Curing

The molded parts are allowed to cure or harden. This can be done at room temperature or in an oven, depending on the type of resin used. The curing process is crucial for achieving the desired strength and durability of the fiberglass components.

7. Demolding

Once the fiberglass has fully cured and hardened, the molded parts (cable molds and cable brackets) are carefully removed from the molds. This process may require some care to avoid damaging the parts.

8. Trimming and Finishing

After demolding, the parts may require trimming and finishing to remove any excess material and ensure they meet the design specifications. This can involve cutting, grinding, and sanding.

9. Quality Control

Conduct quality control checks to ensure that the cable molds and cable brackets meet the required standards and specifications. This may involve visual inspections, measurements, and testing for strength and durability.

10. Assembly and Packaging

If your cable brackets require additional components or assembly, this step involves putting everything together. Once assembled, the final products are typically packaged and prepared for shipping or distribution.

Composite design in the automotive industry should pay attention to 3 principles

(1) High specific strength and high specific stiffness;

(2) The material is suitable for the environment;

(3) High cost performance. In addition, when designing the body, there are some empirical methods, such as: carbon fiber composite materials are used in areas with high stress; plywood composite materials are used in areas where toughness and stiffness are relatively high; laminates can be used in areas with complex geometries.

The performance of composite materials is suitable for the requirements of lightweight body and reduces fuel consumption. The traditional automobile body material is in a single state mainly composed of thin steel plates, which cannot meet the requirements of people’s pursuit of high speed and light weight. the above requirements. The self-weight of the car is reduced by 50kg, and the driving distance of 1L of fuel can be increased by 2Km; if the self-weight is reduced by 10%, the fuel economy can be improved by about 5.5%. Many types of composite materials have gained the stage to display their talents in the process of lightweighting of the body, and have become very proficient in the process of lightweighting of automobiles. The purpose of lightweight vehicles is to save energy and reduce emissions. At the same time, environmental protection has become an indispensable condition for sustainable development strategies, and the development trend of composite materials is moving towards extended service life and renewable direction.

Due to these properties, composite materials find applications in diverse industries, including aerospace, automotive, construction, marine, sports and recreation, and more. Their ability to provide a combination of strength, durability, and versatility makes them a valuable choice for a wide range of engineering and design challenges.