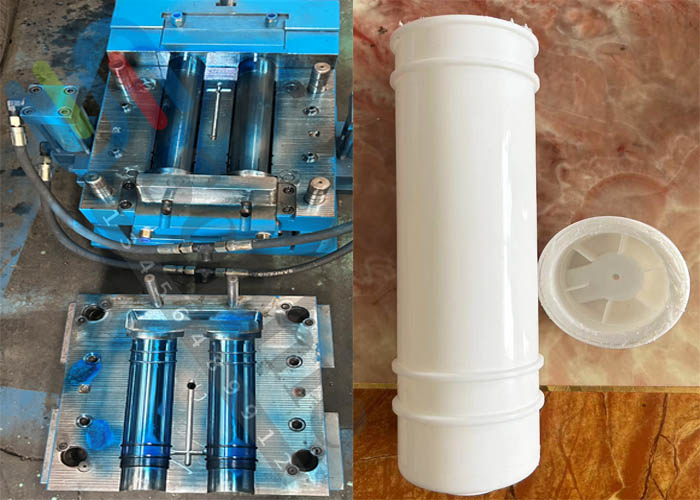

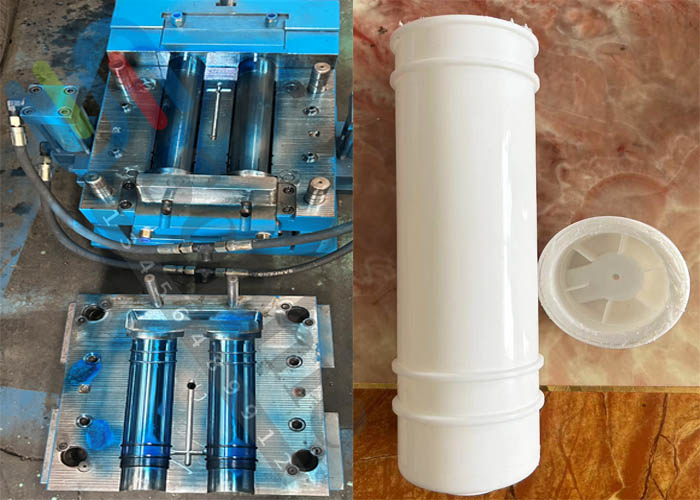

Plastic Water Filter Housing Mold Water purifier mould

Professional customization of plastic injection Water Filter mold water filter Housing Mold,providing high quality plastic injection filter cartridges molds to help you create superior water filtration products by Water purifier mould

Water Filter Housing Mold production factory in China, as an industry leader, we focus on the design and manufacturing of high-quality plastic injection water filter molds. With advanced technology and a professional team to make water purifier mould, we are committed to meeting the individual needs of our customers and providing innovative, durable and efficient solutions. With a focus on quality, sustainability and customer satisfaction, we strive to support your business success. Choose us, explore the future of the water treatment industry with us, and create excellent filter products.

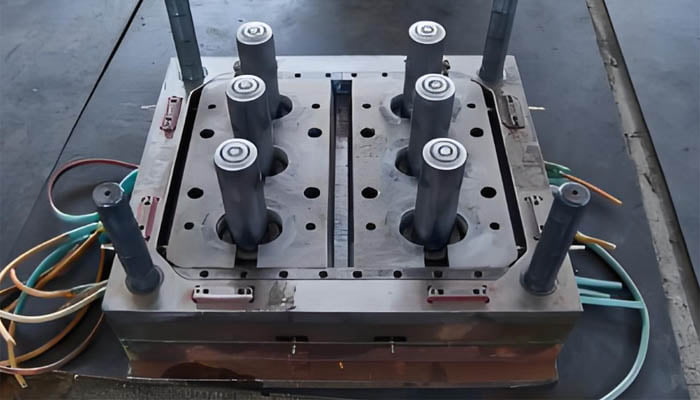

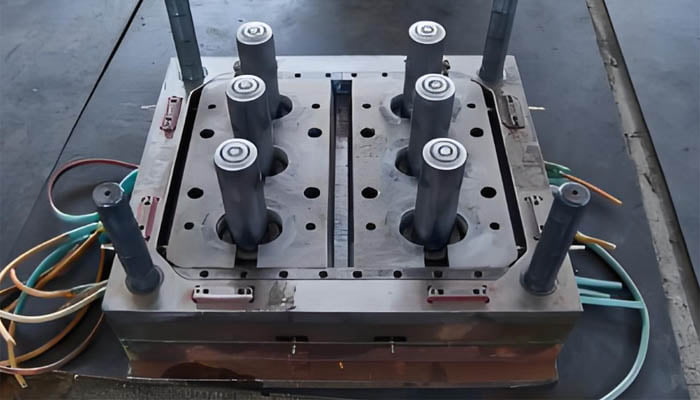

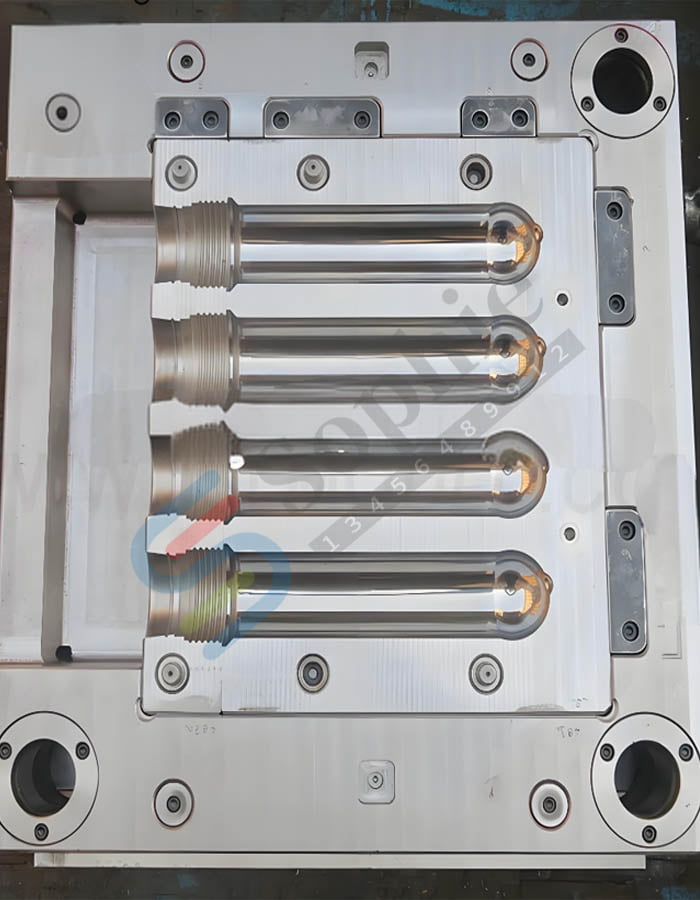

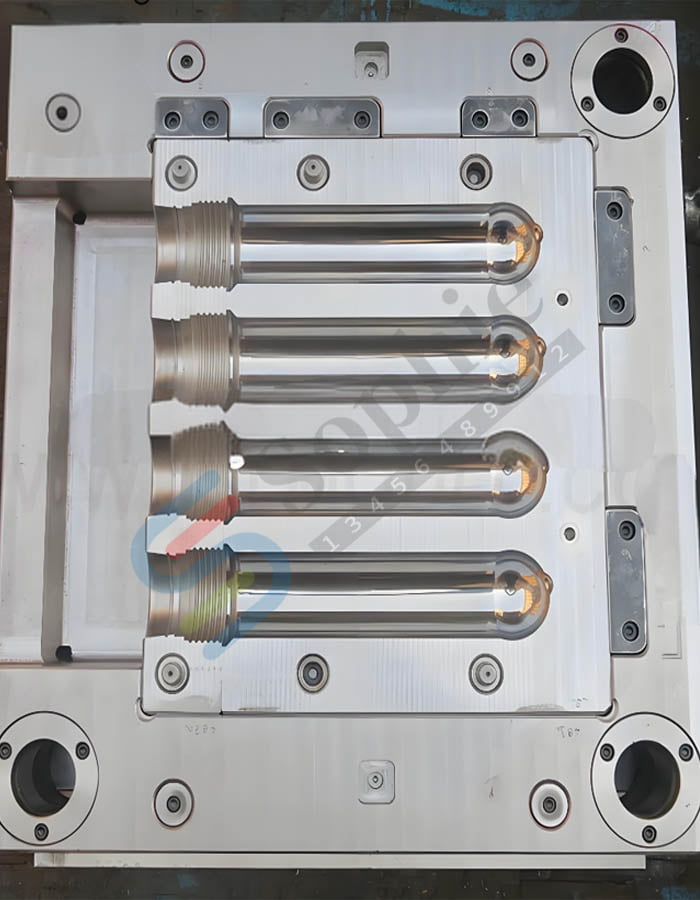

Plastic Water Filter Mold

Plastic Injection Water Filter Housing Mold

Water Purifier Mould

Plastic water filter housing mold is core of the water purification system

Plastic water filter housing molds are the unsung heroes of the water purification industry. They are the backbone of the water filter manufacturing process, ensuring that every component is precisely manufactured to the highest quality and functional standards. In this section, we will delve into the world of injection water filter molds, exploring their types, materials, and the role they play in providing clean water to millions of users.

Access to clean drinking water is a vital issue worldwide. As an important component of water purification equipment, the design and manufacturing quality of plastic injection Water purifier mould directly affect the filtration efficiency and durability of the final product. This article will introduce in detail the types, material selection, manufacturing processes of plastic water filter housing molds and their wide application in the water purification industry.

As a professional manufacturer of plastic water filter housing molds and water purifier molds, we are committed to providing high-quality mold solutions to meet the needs of the global water purification industry. Our products use advanced manufacturing processes and high-quality materials to ensure that each mold can accurately produce water filter housings that meet industry standards.

Our mold design team has rich industry experience and can provide customized mold design services according to the specific needs of different customers. Whether it is a standard type, high-flow type or a special specification mold, we can ensure its stability and durability during the production process, thereby helping customers improve production efficiency and reduce long-term operating costs.

We are well aware of the importance of clean water to human health, so we continue to pursue technological innovation to improve the performance and production capacity of molds. Through continuous quality control and customer service, we have won the trust and support of domestic and foreign customers. Choosing us, you will get a reliable partner to jointly promote the development of water purification technology and provide safer and healthier drinking water to the world.

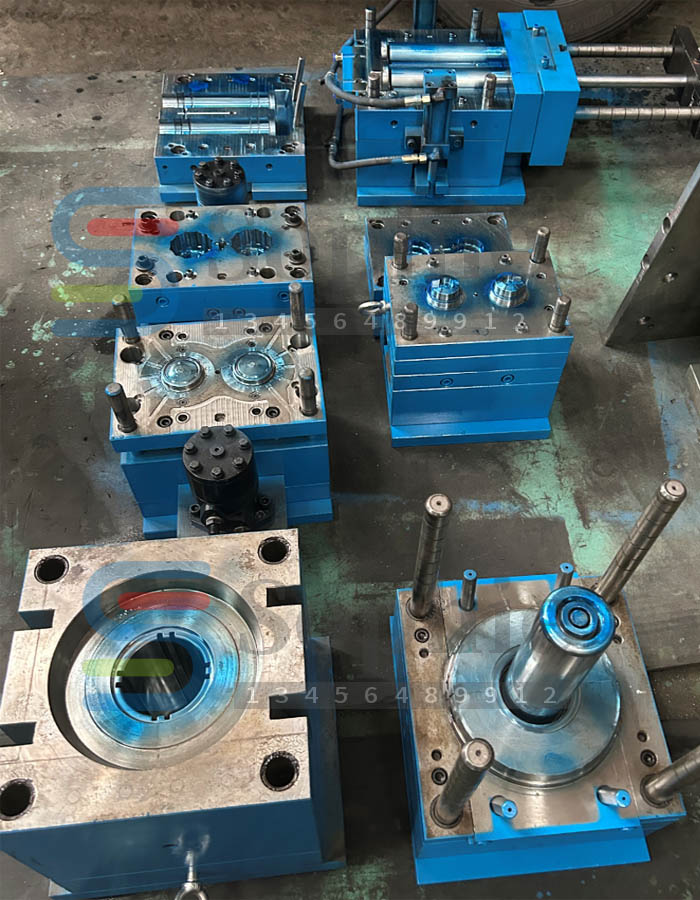

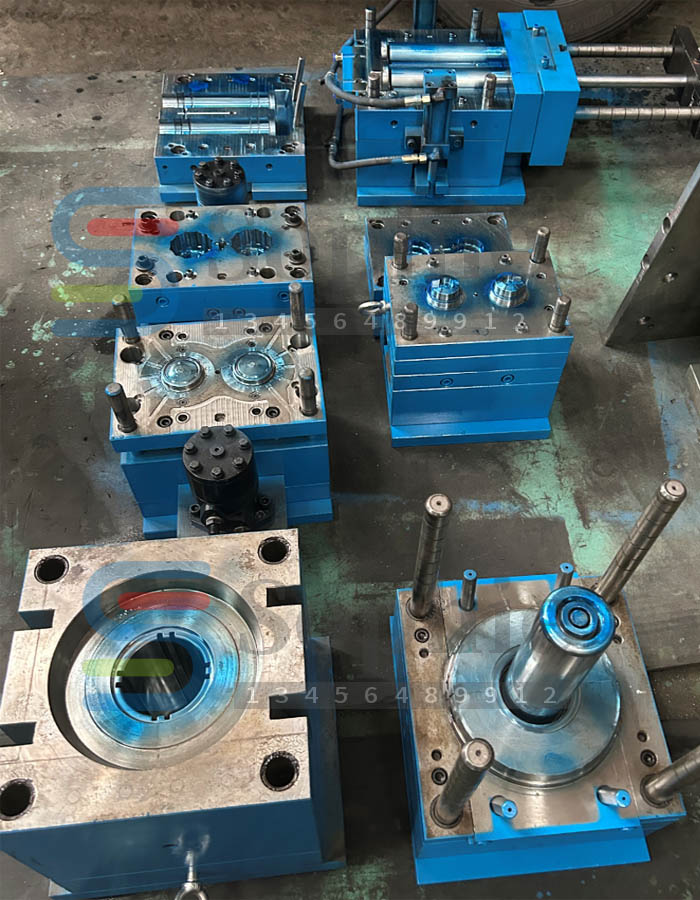

Types of Plastic Water Filter Housing Molds

The types of plastic water filter housing molds are diverse to meet different application scenarios and customer needs.There are several types, each with its own unique features and advantages.

Standard Housing Molds

Designed for everyday use, these molds produce the most common water filter housings found in residential and commercial settings.It meets the manufacturing needs of most water filters on the market. They are generally cost-effective and suitable for large-scale production, ensuring product consistency and reliability.

Custom Housing Molds

Tailored to specific customer requirements, these molds allow for unique designs and special features to meet the needs of different water purification systems.According to customer requirements, molds with specific characteristics are issued to adapt to various special applications, thus providing customers with more personalized and innovative solutions

High Flow Housing Molds

Designed to accommodate higher water flow rates, these molds are ideal for systems that require greater water volume filtration.They are designed for situations where large volumes of water need to be processed, such as industrial water purification or large commercial buildings. These molds can not only withstand high water pressure, but also maintain efficient filtration performance, ensuring high standards of water quality.

Plastic Water Filter Housing Mold and Water Purifier Mold refer to plastic molds used to make water filter housings. These molds are important components of water purification equipment. They produce plastic housings through injection molding, which are then assembled into complete water filters or water purifiers.

They are all made through precise mold design and manufacturing processes to ensure that the produced water filter housing or components have the required dimensional accuracy, surface finish and durability. The quality of these molds directly affects the performance and service life of the final water filter.

In summary, we have a wide variety of plastic water filter housing molds, whether it is standard production or special customization, we are committed to providing the best quality products and services to meet the diverse needs of customers and promote the development of water purification technology.

Water filter houseing material

In addition to steel, the plastic shell produced by the mold may use plastic materials such as PP (polypropylene), ABS, PC (polycarbonate), POM (polyoxymethylene), PA (nylon), etc. These materials have different physical and chemical properties and are suitable for different application scenarios.

Water filter housing mold details

Water filter housing molds are precision tools specifically used to produce plastic water filter housings. They are usually made of high-quality steel to ensure mold durability and production accuracy. Here are some detailed information about water filter housing molds:

Mold material

Water filter housing molds are usually made of high-quality steels such as P20, 718H, H13 and S136, which are favored for their wear resistance, corrosion resistance and processing performance.

Mold hardness

The hardness of the mold is a key factor in its durability. Common mold hardness ranges from 28-32HRC to 55HRC to meet different production needs.

Mold life

High-quality molds are designed to withstand long-term use. Their lifespan can range from 300,000 cycles to more than 1,000,000 cycles, depending on the material and use conditions of the mold.

Mold standards

Some industry standards such as LKM, EDM, etc. may be followed during the mold manufacturing process to ensure the quality and performance of the mold.

Molding method

Water filter housing molds are usually made using injection molding, which is a process in which plastic material is heated to a molten state and injected into the mold cavity, and then cooled to form the desired shape.

Runner system

The mold may be equipped with a cold runner or hot runner system, the latter of which can improve material utilization and reduce waste.

Surface treatment

The mold surface may be polished, mirror polished, textured, painted, brushed or sandblasted to improve its performance and appearance.

Mold accuracy

High-precision molds can ensure the consistency of product dimensions, and the accuracy is usually controlled within ±0.03 mm.

Delivery time

The manufacturing and delivery time of the mold is usually between 50 and 60 days, depending on the complexity of the mold and the production capacity of the manufacturer.

Through these details, we can see that the water filter housing mold has strict standards in material selection, manufacturing process and performance requirements to ensure that the final product can meet the needs of the market and consumers.

Water filter housing mold manufacturing process

The manufacturing process of the water filter housing mold is a complex and delicate process involving multiple specialized stages to ensure the high quality and precision of the mold. The following is an expanded description of the process:

Market Research and Demand Analysis

Before designing, market research is conducted to understand customer needs and industry standards, and to analyze the intended use and performance requirements of the filter housing.

Conceptual Design

Based on the market research results, the designer preliminarily conceives the geometry and functional characteristics of the mold and determines the basic structure of the water filter housing mold.

Detailed Design and Engineering

Use advanced CAD software such as AutoCAD, SolidWorks or UG NX to create a 3D model and 2D engineering drawings of the filter mold to ensure the accuracy and feasibility of the design.

Mold Material Selection

According to product requirements and budget, select suitable water filter mold steels such as P20, H13 or 718H, which have different heat treatment capabilities and wear resistance.

CNC Machining and Programming

Use CNC machining centers to precisely process plastic filter mold materials according to programming instructions to form the mold cavity and core.

Electrical Discharge Machining (EDM)

For complex or fine mold features, use EDM technology for precise etching at the micron level.

Mold surface treatment

Surface treatment such as polishing, coating or hardening is performed to improve the durability, corrosion resistance and demolding performance of the injection filter mold.

Mold component manufacturing

In addition to the main cavity and core, auxiliary components such as sliders, ejectors, guide pins, guide sleeves, etc. need to be manufactured.

Assembly and debugging

All mold components are assembled accurately according to the design drawings and debugged to ensure that all parts of the mold work together to achieve precise molding.

Mold trial

Mold trial is carried out on the injection molding machine, and small batch production is carried out using actual plastic materials to check the performance of the mold and the molding quality of the product.

Quality inspection

Strict quality inspection is carried out on the trial mold products, including dimensional accuracy, surface finish and physical property tests.

Mold optimization

According to the results of the mold trial, the mold is adjusted and optimized as necessary to solve any potential problems.

Final acceptance

The customer accepts the optimized mold to ensure that the injection Water purifier mould meets all technical requirements and production standards.

Mold maintenance and care

Provide maintenance and care guidance for the plastic Water purifier mold to ensure the stability and long life of the mold during the production process.

Technical support and service

Water purifier mould manufacturers provide continuous technical support and services to help customers solve problems encountered during the production process.

Applications of Plastic Water Filter Housing Mold

Residential Use: Used in homes to ensure clean and safe drinking water.

Commercial Use: In restaurants, offices, and other commercial spaces, water quality is critical.

Industrial Use: Used in large-scale water treatment plants and industrial filtration systems.

The applications of plastic water filter housing molds are very wide, they play a vital role in many fields to ensure the purity and safety of water. The importance of plastic water filter housing molds in modern society, they not only improve water quality, but also promote healthy and safe living standards.

Through this detailed manufacturing process, the water filter housing mold can ensure the production of high-quality water filter products to meet the diverse needs of the market.

Plastic water filter housing molds are essential in the production of water purifiers and play a key role in protecting public health by ensuring access to clean water. By understanding the different types of molds, materials, and manufacturing processes, manufacturers can make informed decisions to create the best water filtration systems.

Explore our range of plastic water filter housing molds and take the first step towards enhancing your water purification solutions. Contact us today to discuss your specific needs and let us help you create a mold that is perfect for your needs.