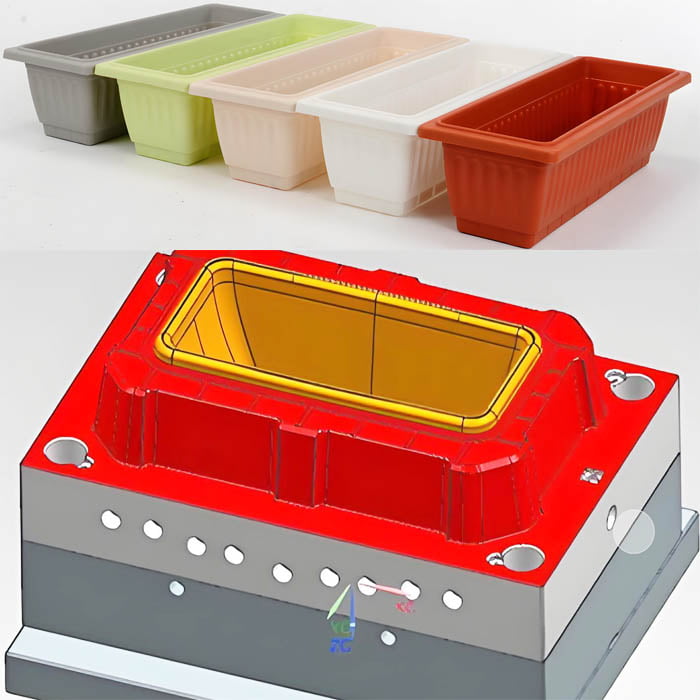

Injection Flower Pot Mold

Choosing our plastic injection flower pot molds will not only speed up your flower pots production, but also lead the horticultural planting industry towards a prosperous future.

Welcome to the leading plastic injection flower pot mold manufacturer – we focus on providing innovative, efficient and sustainable flower pot mold production solutions to global customers to help the development of the horticultural industry. Our advanced plastic flower pot mold equipment, combined with superb craftsmanship and strict quality control processes, ensures that each injection flower pot mold achieves unparalleled precision and durability.

Our product line covers a variety of flower pot molds in various sizes, shapes and designs, designed to meet the unique needs of different customers. Whether it is a small indoor plant enthusiast or a large commercial gardening project, our molds can provide the perfect injection mold solution.

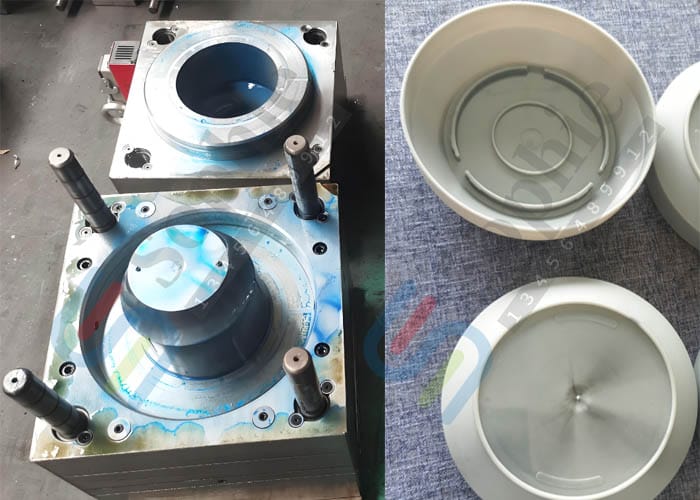

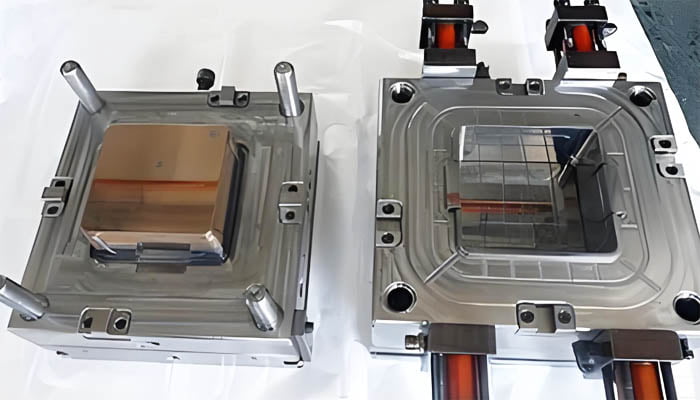

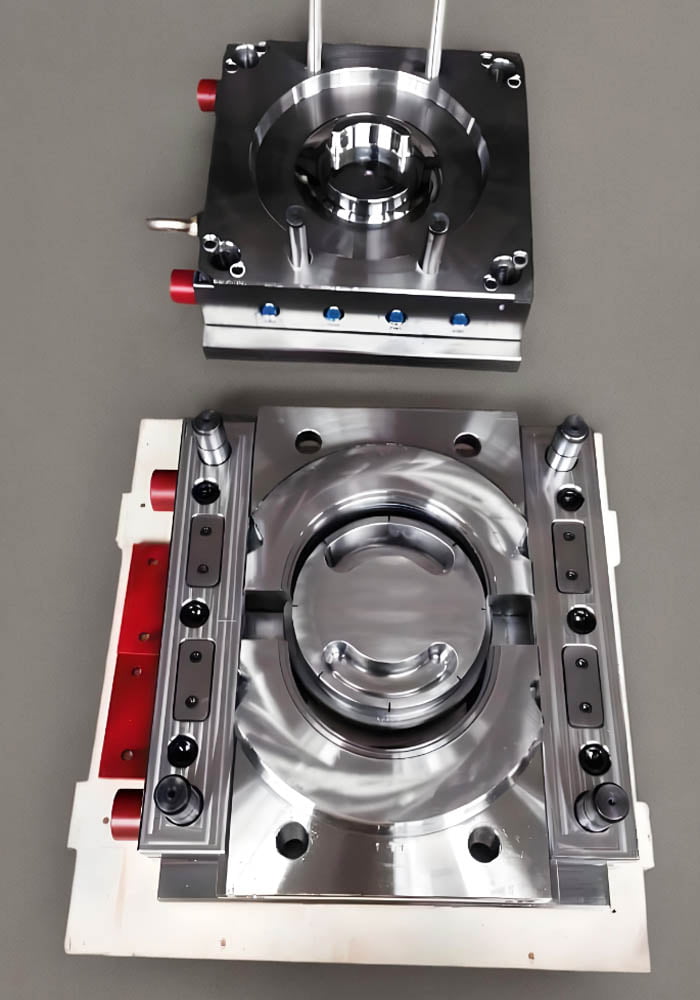

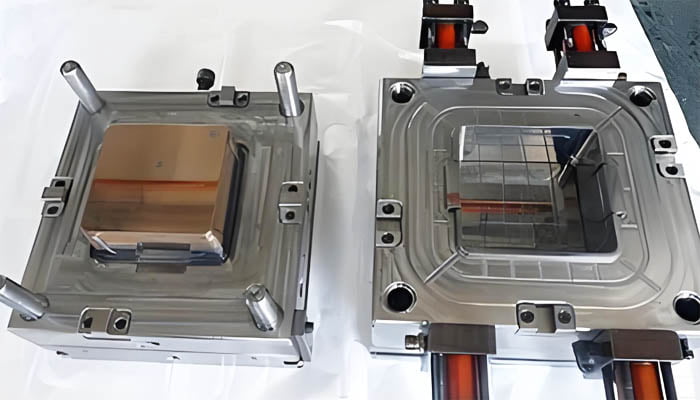

Plastic Injection Flower Pot Mold

Plastic Plant Pot Mold

Plastic Injection Planter Mold

Plastic injection flower pot mould Plant Pot Molds manufacturer

Plastic Injection Flower Pot Mold production factory

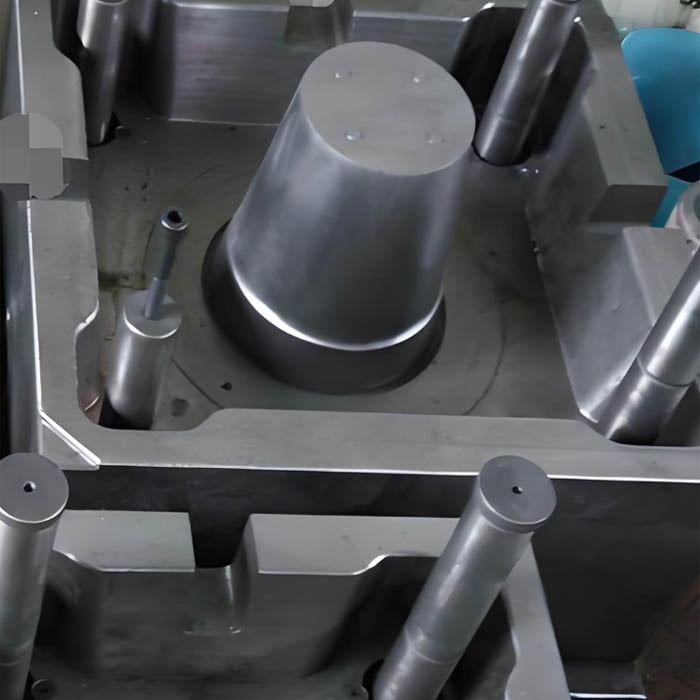

Plastic injection flower pot molds are specialized tools used to produce plastic flower pots. We are plastic flower pot mold factory in taizhou,all kinds of plastic plant pot mold customized.They are manufactured through the injection molding process to create plastic flower pots of various shapes and sizes. Plastic injection planter molds are usually made of metals, such as steel or aluminum alloys, because these materials have enough strength and durability to withstand the high pressure and temperature during the injection molding process.

Injection Flower Pot Mold production factory, we focus on providing high-quality injection flower pot molds to customers around the world and are committed to promoting innovation and development in the gardening industry.

Our team consists of experienced designers, engineers and technical support staff who are committed to continuous innovation to adapt to the ever-changing market needs. Our goal is to help customers achieve the development of horticultural products through excellent products and services, while promoting the sustainable development of the entire industry.

Choosing us means choosing a reliable and professional partner. Let us work together to promote the development of the planting horticulture industry and cultivate a greener and more beautiful world with innovative plastic injection flower pot molds.

At our Plastic Injection Flower Pot Mold production factory, we proudly provide well-designed plastic flower pot molds to customers all over the world. Our professional team constantly explores and implements innovations in gardening container designs to meet the ever-changing market demands.

What design innovations do our Plastic Injection Flower Pot Molds feature

As a professional Plastic Injection Flower Pot Mold manufacturer, our flower pot mold design incorporates several innovative features to meet the market demand for efficient, sustainable and beautiful flower pots. Here are some of the innovations in our mold design:

Precision Engineering

Our plastic flower pot molds are processed with advanced CNC machinery to ensure the accuracy of every detail, so as to produce flower pots with consistent size and beautiful appearance

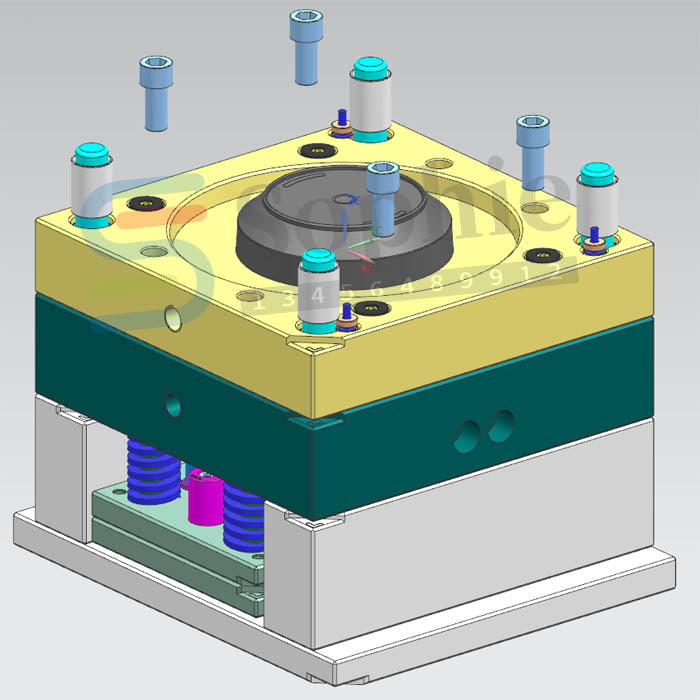

Efficient injection molding system

Our injection flower pot mold design includes cold runner and hot runner systems to improve material utilization efficiency and production speed and reduce waste generation

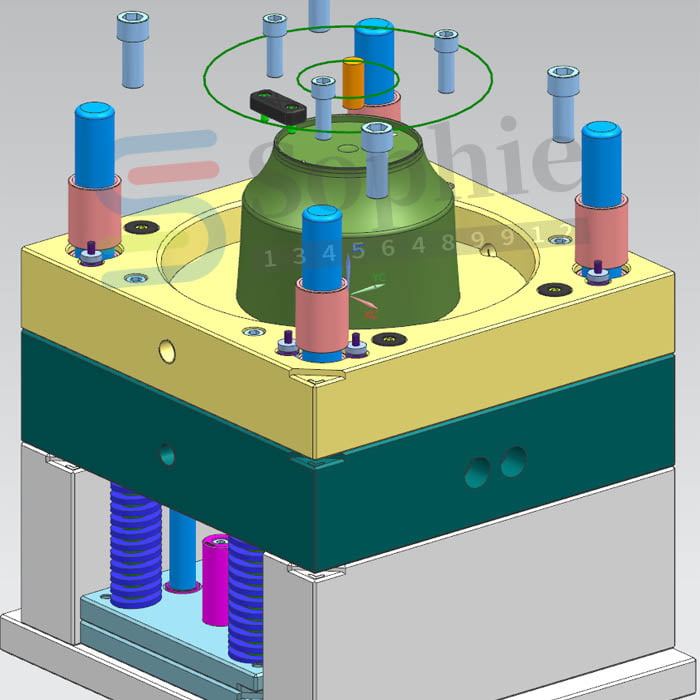

Innovative demoulding design

Through the optimized demoulding system, including ejector and side slider mechanism, the flower pot is ensured to be easily demoulded and the damage rate of the finished product is reduced.

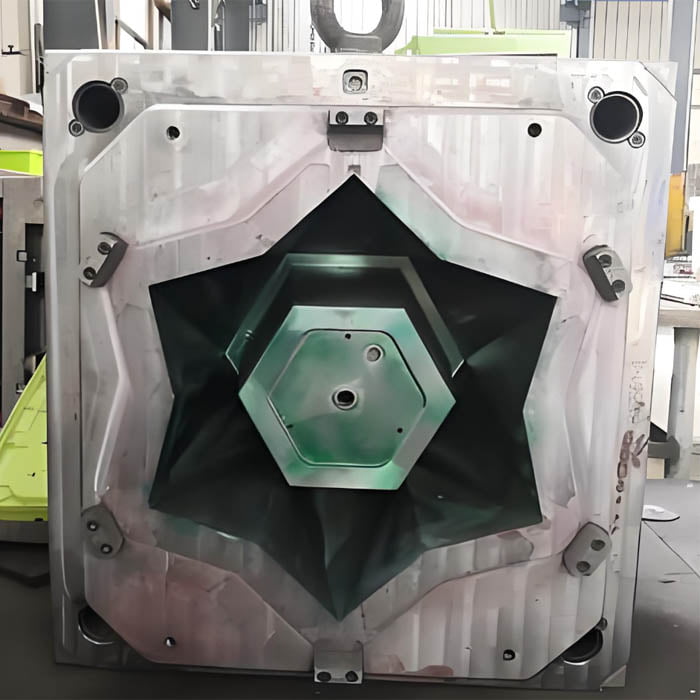

Diverse textures and designs

Our plastic plant pot molds can produce flower pots with different textures and patterns, such as imitation rattan, imitation wood grain, etc., to increase the market appeal of the product.

Simulation analysis technology

During the injection plant pot mold design stage, we use simulation software such as Moldflow to perform flow and cooling analysis, predict and optimize the molding process, and ensure the efficient operation of the mold

Long life and durability

Our plastic injection flower pot molds are made of high-quality steel and surface treatment technology, such as nickel coating, to improve wear resistance and corrosion resistance, ensuring long-term and stable use of the mold.

Customized service

We provide customized services to design and manufacture unique flower pot molds according to the specific needs of customers to meet the needs of personalized markets.

Through these innovations, our Plastic Injection Flower Pot Mold not only improves production efficiency and product quality, but also provides customers with more competitive and attractive products. We are committed to promoting the development of the horticultural planting industry through continuous technological innovation.

Design of Plastic Injection Flower Pot

Among the many flowerpot materials, plastic flowerpots occupy a significant share of the market due to their low production costs and fast production cycle, with approximately 40% market share.

We specially use PP (polypropylene) material to manufacture these lightweight and durable plastic planting containers. This material makes the flower pots thin-walled and lightweight, and the production speed is extremely fast. The production time of a flower pot can be as short as 6 seconds. In addition, our products are easy to stack, significantly reducing transportation costs, making our plastic flower pots popular worldwide.

Our Plastic Injection Flower Pot Mold production facility focuses not only on the product’s functionality, but also on its aesthetics and environmental sustainability. Our design team is committed to creating planters that are both functional and attractive to enhance consumers’ gardening experience and contribute to a green future for the planet.

Key Considerations in the Manufacturing Process of Flower Pot Mold

A cup holder, also commonly known as a cup holder or beverage holder, is a common automotive accessory designed to safely store beverage containers while driving. The following are some of the main application scenarios of cup

CNC machining

For CNC machining of flower pot molds, we will choose the appropriate processing method according to the shape and structure of the flower pot product design. For example, round flower pots are mainly processed by CNC lathes, while square or other shaped flower pots are first rough-machined by CNC milling machines and then fine-machined to ensure that the accuracy of the mold fully meets the design specifications.

Electrospark machining (EDM)

In plastic injection flower pot mold manufacturing, some complex reinforcement parts are difficult to complete by CNC machining. For these parts, we usually use EDM technology. This processing method may take a long time and the cost is relatively high. Therefore, when designing flower pot products, we will try to minimize the use of such reinforcements to achieve cost-effectiveness.

Polishing

The cavity polishing requirements of the flower pot mold are extremely strict. It needs to be manually polished along the side of the flower pot, followed by mechanical polishing to achieve B2 grade or higher polishing requirements. If the polishing is uneven, the surface of the product may have ripples, affecting the appearance quality of the flower pot.

Our production plant is committed to providing customers with high-quality plastic flower pot molds through these fine processing steps to meet the high standards of the horticultural industry for beauty, durability and cost-effectiveness.

Rich experience for Plastic Injection Flower Pot Mold making

In our rich experience in flower pot mold manufacturing, we found that the key to product design is to determine the appropriate wall thickness. Careful design can not only reduce the weight of the product, but also simplify the production process, making the injection molding process smoother. In addition, the accuracy of the processing equipment is also crucial to the quality of the injection flower pot mold. High-precision equipment can complete the mold processing in one go to ensure quality.

In addition to design, the material selection of plastic flower pots is also extremely important for the injection molding effect. For example, some flower pots may require a mixture of PP and PE, while others may require the addition of anti-UV additives to improve the durability and appearance of the product. Our professional team will carefully select and adjust the material formula according to the specific needs of the product to achieve the best injection molding effect.

Through this experience and attention to detail, we are able to provide plastic flower pot molds that are both beautiful and practical to meet the high standards of our customers. We are committed to promoting the development of the horticultural container manufacturing industry through continuous technological innovation and material research.

What's the benefits choose our plastic flower pot moulds

Choosing our plastic flower pot moulds is a decision that comes with a multitude of benefits, designed to enhance your production capabilities and deliver superior end products. Here’s why our moulds stand out:

Precision Engineering

Our plastic flower pot moulds are crafted with meticulous attention to detail, ensuring that every flower pot produced is consistent in size, shape, and quality. This precision is a result of state-of-the-art CAD/CAM design and CNC machining processes.

Durable Construction

Made from high-quality steel, our plastic flower pot moulds are built to last. They can withstand the rigors of high-volume production, reducing the need for frequent replacements and minimizing your long-term costs.

Customization

We understand that every production line has unique requirements. That’s why we offer fully customizable plastic injection flower pot moulds, allowing you to produce flower pots in various shapes, sizes, and designs to cater to diverse market demands.

Efficient Production

Our flower pot molds are designed to optimize the injection molding process, with features like efficient cooling systems that reduce cycle times and increase your output without compromising on the quality of the pots.

Cost-Effective Solutions

While offering premium quality, our injection flower pot moulds are priced competitively, ensuring you receive the best value for your investment. This affordability makes high-quality moulds accessible to businesses of all sizes.

Rapid Turnaround

We pride ourselves on our efficient production processes, which means you can expect quick delivery times for your plastic plant pot moulds. This speed ensures you can start your production runs sooner and meet market demands faster.

Innovative Design

Our design team is continuously innovating to incorporate the latest trends and functionalities into our moulds. This innovation ensures that your plastic flower pots remain contemporary and appealing to customers.

Reliable Customer Service

We offer unparalleled customer support, from initial consultation to after-sales service. Our team is always ready to assist you with any questions or concerns you may have regarding your plastic injection planter moulds.

Quality Assurance

Rigorous quality control checks at every stage of production ensure that our flower pot moulds meet the highest industry standards. We guarantee that our moulds will produce flower pots of exceptional quality.

By selecting our plastic flower pot moulds, you’re not just choosing a tool for production—you’re investing in a partnership that drives the excellence of your product and the success of your business.

Unlock a world of creative potential with our premium plastic flower pot moulds. Craft stunning and dynamic plant containers that will mesmerize your clientele and grace any environment. Embrace a new era of productivity and innovation with our dependable and forward-thinking mould technology.

Key Factor Selecting the Right Plastic for Flower Pot Moulds

There are several key factors to consider when choosing the right type of plastic to make a plastic flower pot mold:

- Material durability: Choose durable materials such as PP (polypropylene) or PE (polyethylene), which have high resistance to environmental factors such as temperature changes and UV exposure and are suitable for outdoor use.

- Processing performance: The selected material should have good flowability and melt index to ensure uniform filling of the mold and reduce the generation of bubbles and shrink marks during the injection molding process.

- Cost-effectiveness: Consider the cost of the material and its impact on the price of the final product. Some materials may be more economical, but may compromise on durability or appearance.

- Sustainability: Choose recyclable or biodegradable materials to reduce environmental impact and meet the trend of sustainable development.

- Appearance and texture: Depending on the end use and market positioning of the flower pot, choose materials that can provide the desired appearance and texture. For example, some plastics can imitate the texture of ceramic or wooden flower pots through special techniques during the injection molding process.

- Color and additives: Consider whether additives such as color or UV stabilizers need to be added to enhance the aesthetics of the flower pot or extend its service life.

- Safety of materials: Make sure the selected materials are harmless to plants and do not contain ingredients that are harmful to plant growth.

- Compatibility of design and function: The selected materials should be able to support specific functions in the flower pot design, such as drainage holes or other special structures.

The manufacturing process of plastic flower pot molds usually includes design, CNC machining, assembly, mold trials and production. The design stage involves using CAD software to create a 3D model of the mold, which is then precision-machined by CNC machines. Once the mold is assembled, a mold trial is conducted to test its performance and the quality of the flower pots produced, and adjustments are made if necessary. Once the mold is confirmed to be correct, it can be used for mass production of plastic flower pots.

The manufacture and use of plastic injection flower pot molds is a complex process that involves multiple fields such as materials science, mechanical engineering and design innovation. By continuously optimizing these molds, it is possible to increase production efficiency, reduce costs, and create plastic flower pots that are both beautiful and practical.

By considering these factors comprehensively, you can ensure that the plastic flower pot molds produced not only meet production needs, but also produce flower pot products that are both beautiful and practical.

Applications of flower pot moulds in the industry

Plastic flower pot moulds have been successfully applied across a variety of industries, showcasing their versatility and impact. Here are some examples of their successful use:

Gardening and Horticulture: Plastic flower pot moulds are widely used in the gardening industry to produce pots for various plants, with production times and costs significantly reduced compared to traditional materials. These pots are not only safer and more durable but also cater to the modern lifestyle where gardening has become a popular hobby.

Commercial Landscaping: Businesses and retailers use plastic flower pots for decorating storefronts, parks, and public spaces. The durability and weather resistance of these pots make them ideal for outdoor use, enhancing the aesthetics of commercial settings.

Community Gardening and Urban Farming: The rise in community gardening and urban farming can be attributed to the ease of use and low maintenance of plastic flower pot moulds. They facilitate the setup of small gardens in urban environments, promoting green spaces in cities.

Educational Institutions: Schools and educational centers use these moulds for teaching gardening projects, allowing students to learn about plant life cycles and the environment, fostering an appreciation for nature.

Research and Development: In research, plastic flower pot moulds are used for controlled experiments and plant growth studies. The uniformity of the pots ensures consistent data collection for accurate observations.

Sustainability: The industry is focusing on eco-friendly materials and sustainable manufacturing processes to address environmental concerns. Developments in biodegradable and compostable moulds aim to reduce plastic waste and offer greener options for gardening.

Customization and Personalization: The ease of customization allows businesses and individuals to create unique pots with logos, names, or artwork, making them ideal for gifts or promotional items.

International Flower Trade: The global reach of Chinese-made plastic flower pot moulds has facilitated the international flower trade, enabling efficient and safe transportation of plants across borders.

Home Gardening: The accessibility and low maintenance of plastic pots have encouraged more people to engage in home gardening, making it easier for amateurs to start their green journey.

Integration of Technology: Innovative technologies like smart pots that monitor soil conditions are being integrated with plastic flower pot moulds, enhancing plant care and cultivation.

These examples highlight the significant role plastic flower pot moulds play in modern gardening, commercial applications, and environmental sustainability. As technology advances, their role is expected to grow, shaping the future of gardening and plant cultivation.

Chinese manufacturer with a 20-year track record, we pride ourselves on delivering exceptional plastic injection flower pot moulds that transform the art of pot making into a seamless and enjoyable experience. Trust our expertise to provide you with top-tier products and service, making your flower pot creations a breeze and a delight.

Step into the future of flower pot manufacturing by reaching out to us. Experience the excellence of our Chinese craftsmanship in plastic flower pot moulds. Boost your operations to new heights, enchant your customers, and leave an indelible mark in the market. Seize this exclusive opportunity today!

Place your order now to enjoy a winning combination of superior quality, streamlined efficiency, and cost-effectiveness. Allow us to become your reliable ally in the crafting of exquisite plastic flower pots. Join hands with us and let’s bring your floral visions to splendid fruition.