Plastic flower pot mold injection plant pot mould

Plastic flower pot mold injection plant pot mould: A Growing Market in Mexico.

Plastic flower pot mold is a kind of injection mold specially used for producing plastic flower pots. It usually includes the following key parts.The demand for plastic plant pots and planter molds has been on the rise, driven by the growing interest in home gardening and urban greening initiatives. Mexico, with its strategic location and robust manufacturing ecosystem, has emerged as a key player in the production of plastic injection molds for plant pots. In this blog, we will explore the factors contributing to Mexico’s prominence in this market and the benefits of sourcing plant pot molds from Mexican manufacturers.

Plastic flower pot mold injection plant pot mould Detailed Information

- Plastic flower pot mold injection plant pot mould

- Mold cavity:1

- Hot runner:1 drops with heating coils

- Plastic flower pot mould cavity steel: P20H and 718H

- Plastic flower pot mould core steel: P20H and 718H

- Plastic material:HDPE

- Mold Cycle time:30-35 Secs

- Delivery time:40-45 days.

Keys of flower pot mold

Gating system

Includes main runner, branch runner, gate and cold well. These components are responsible for guiding the molten plastic from the nozzle of the injection molding machine into the cavity of flower pot mold. For deep-cavity plastic parts such as flower pots, straight gates are usually selected because they have a short process, low pressure loss and are easy to mold.

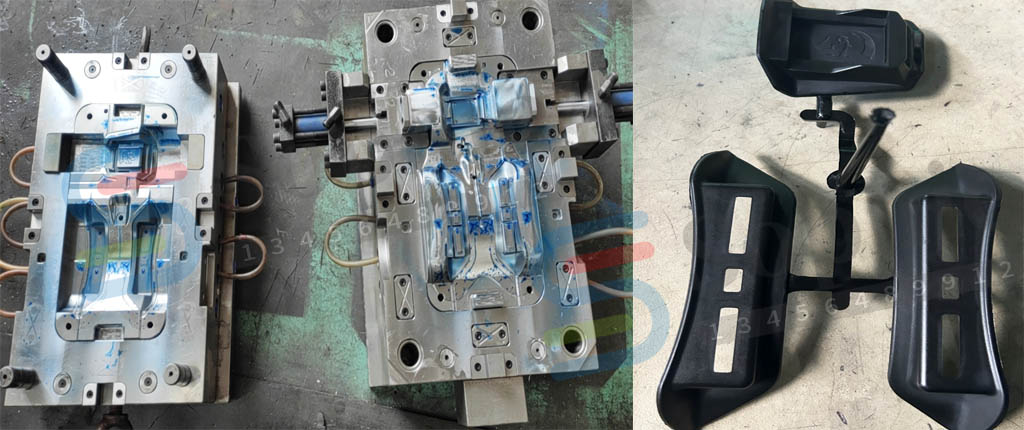

Core and cavity

These are the core parts of flower pot mold, and their shapes directly determine the appearance of the molded plastic flower pot. The design of the core and cavity needs to take into account the fluidity of the plastic, the cooling speed and the convenience of demolding.

Ejection system

After the plastic is cooled and solidified, the ejection system is responsible for pushing the molded plastic flower pot out of the flower pot mold. The ejection system can adopt push plate type, air blowing and other methods to ensure that the plastic flower pot can be demolded smoothly without leaving traces on the surface.

Temperature control system

In order to meet the plastic flower pot mold temperature requirements during the injection molding process, a injection flower pot mold temperature control system is needed to adjust the temperature. Common ones include cooling water, hot water, hot oil and electric heating systems.

Exhaust system

Exhaust grooves are usually set on the parting surface of plastic injection flower pot mold to ensure that the gas in the plastic plant pot mold cavity is discharged smoothly and avoid the formation of bubbles during the molding process.

The advantages of plastic injection flower pot molds include high production efficiency, high product precision, stable product performance, and a wide range of applications.

However, high manufacturing costs, limited applicable products, difficult mold maintenance, and high investment risks are also disadvantages that need to be considered.

When designing plastic injection flower pot molds, factors such as material selection, analysis of plastic products, and mold structure design also need to be considered. For example, polypropylene (PP) is a common material for making plastic flower pots because it has the characteristics of light weight, multiple colors, corrosion resistance, easy manufacturing, and low price.

In general, plastic injection flower pot molds are indispensable tools in the production of plastic products, and their design and manufacturing quality directly affect the quality and production efficiency of plastic flower pots.

Superiority of Our Plastic flower pot mold injection plant pot mould

Masterfully Crafted in China

Our plastic injection plant pot are manufactured with pride in China, a hub of precision and exceptional workmanship. Each Plastic Injection Planter mold is meticulously inspected through stringent quality control processes to guarantee superior design and reliable performance.

A Comprehensive one station solution

Eliminate the need to scout multiple suppliers for diverse mold needs. We provide an extensive selection of molds to suit a variety of flower pot designs you wish to create. Whether you’re looking for petite or grand, classic or modern styles, we have the ideal mold for you.

Fast delivery

Quick Turnaround for Your Convenience,we recognize the significance of punctual delivery for our clients. Thanks to our efficient production

Affordable Excellence

We’re committed to making top-tier quality accessible without breaking the bank. Our molds are priced to offer you the best value, so you can invest more in your project and less on overheads. With our molds, you get a winning combination of affordability and high-end quality.

Elevate your product line with our high-quality Plastic Injection plant pot mold Planter Mold, crafted to help you produce stunning pots that will delight your customers and beautify any environment. Our molds are the key to diversifying your offerings and boosting your market presence.

Flower pots were traditionally made from terracotta which is too heavy, easy broken and only mono color. In order to get lightweight and more drop-proof, plastic flower pots become more popular on market. Moreover, plastic flower ports could be more colorful and different design. Hence, it become an important decorative element in the interior. Suitable for all kinds of plants, convenient management and it can be used at balcony, roof, living room, office and so on.

WS Mould is renowned for its comprehensive approach to plastic injection flower pot mold design, where every component, from the smallest screw to the largest nozzle, is meticulously planned. This attention to detail ensures that the entire mold is transparent and error-free. Customers choose WS Mould for the creation of injection molds for high-quality flower pots because of this commitment to precision and clarity in every aspect of the mold design process. By leaving no detail unaddressed, WS Mould minimizes the potential for mistakes and delivers molds that are ready to produce top-tier plastic flower pots.