CNC Machining for Plastic & Metal

Insert injection molding can be save savings

Structurally more stable!

What is CNC Machining ?

CNC Machining (numerical control machining) refers to a process method for machining parts on CNC machine tools. The process rules of CNC machine tool processing and traditional machine tool processing are generally consistent, but there have also been significant changes. A machining method that uses digital information to control the displacement of parts and tools. It is an effective way to solve the problems of changeable parts variety, small batch, complex shape and high precision and realize efficient and automatic processing.

Parts can be cut out with quite precision and can be easily & fast replicated by CNC machining.

What are the benefits of CNC machining

1. CNC Rapid Prototyping: With the development of rapid prototyping technology, it is widely used in the mold manufacturing process. If we need to lanuch up a new plastic injection molding project, CNC Rapid plastic Prototyping parts to check a product’s design ,which can effectively improve the first-time success rate of mold manufacturing.

2. Small Production Run: CNC machining is quite situable for a small quantity of parts productions. It doesn’t need to create mold, so you can save money and time by CNC machine to creating the new product. In generally,CNC machining is good to runs under 50 pieces, when you need to get over 100 pieces product and it becomes cheaper to produce the parts by injection molding.

3. Quick Turnaround Time: It is different from plastic injection molding where a mold has to be produced first and then produce the parts, CNC machining directly machined parts. This technology can carry out rapid trial production of new products, and the production cycle is only about 1/4 of the traditional technology.

4. High Precise Parts: Due to CNC machining is controls by computer,the machine movement, the machine tools can all move precisely. This make CNC machining have a good and high precise manufacturing process for required parts.We will often hold tolerances to within +/- 0.2mm – 0.3mm.

CNC machining can be produce more robust parts compared with 3D printing. Therefore, it can be machined to the same conditions as the eventual injection molding production parts.

CNC machined plastic material

CNC machining is a good choice for producing prototypes parts and low-volume plastic parts. The parts materials processed by CNC are mainly as follows:

- ABS

- HDPE

- Nylon

- PC

- PMMA (Acrylic)

- POM

- PVC

- PP

The CNC machining center is suitable for processing a wide range of metal materials, non-ferrous metals, cast iron, cast steel, low carbon steel, medium carbon steel and alloy steel, abrasive steel, quenched and tempered steel and hardened steel and other materials can be processed, the important thing is Corresponding tool materials should be selected, such as tungsten steel knives, cemented carbide, cubic boron nitride, ceramic blades, diamond drills, etc.

CNC machined metal material

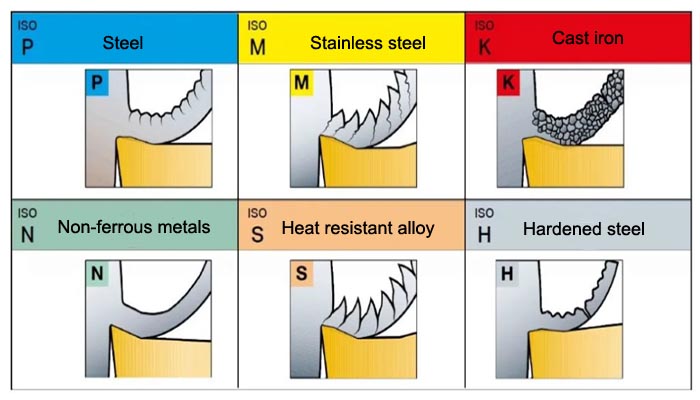

In metal cutting CNC machining, there will be different workpiece materials, and different materials have different cutting formation and removal characteristics. How can we grasp the characteristics of different materials? ISO standard metallic materials are divided into 6 different type groups, each with unique properties in terms of machinability, which will be summarized separately in this article.

Metal materials are divided into 6 categories:

(1) P-steel

(2) M-stainless steel

(3) K-cast iron

(4) N-non-ferrous metals

(5) S-heat-resistant alloy

(6) H-hardened steel

Types of CNC Machines

There has many types of CNC machines, each model with its own functionality to machine different types of parts in different ways.

CNC product processing and CNC parts processing

wsmcmold has mature and perfect production technology, fast delivery, reasonable price, and provides excellent and fast processing services for all customers.

1. CNC Mills: CNC milling machine in English means a milling machine controlled by digital signals of an electronic meter. It is an automatic processing equipment developed on the basis of general milling machines. The processing technology of the two is basically the same, and the structure is somewhat similar. CNC milling machines are divided into two categories: without tool magazine and with tool magazine. Among them, the CNC milling machine with a tool magazine is also called a machining center.

2. CNC Lathes: CNC lathe is one of the most widely used CNC machine tools. It is mainly used for cutting inner and outer cylindrical surfaces of shaft parts or disc parts, inner and outer conical surfaces of arbitrary taper angles, complex rotating inner and outer surfaces, and cylindrical and conical threads, etc., and can perform grooving, drilling, reaming and reaming. Holes and borings, etc.

3. CNC Plasma Cutters: CNC plasma cutters use the same technology as other CNC machines. The main difference is that a plasma cutter cuts parts out of a large, flat metal blank instead of a block. It also only moves the tool tip along two axes.

Get an instant quote right now!

Go to our plastic injection molding and CNC machining case studies page to see how we helped customers on their projects.