Bulletproof Plate Mold

As your trusted bulletproof plate mold solution provider in China, WS mold has the ability to provide perfect quality and acceptable Bulletproof plate mould prices.

Why WS MOLD is Expert in Bulletproof plate mold

WS MOLD is committed to providing the best services and satisfaction to all customers from different countries. We handle optimizations, formulations, and other production process to ensure high-class compression bulletproof plate mold supplies. We only focus on supplying quality Bulletproof plate mold and related tactical bulletproof products mold design support. We are ballistic plate molds professional manufacturer with more than 20 years experience, good service, factory direct sales, trustworthy, speak with quality, conquer with strength,welcome to join us !

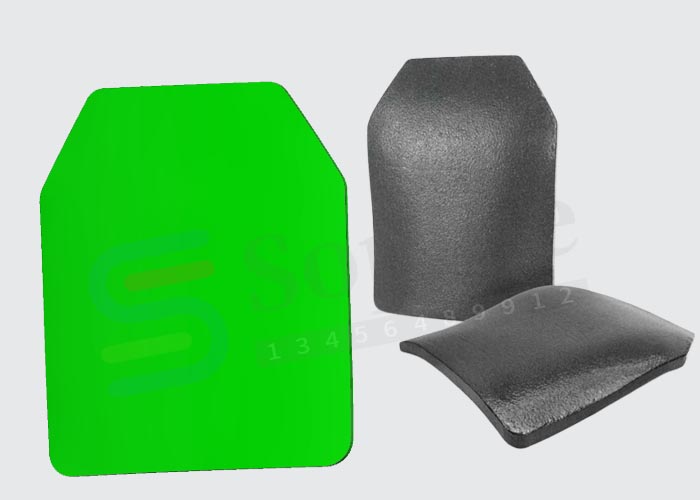

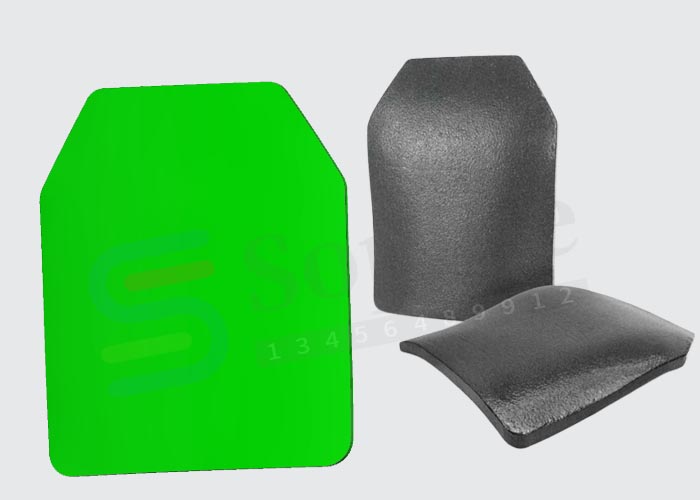

UHMWPE Bulletproof Plate Mold

We are good at producing Bulletproof plate mold by compression molding molding, which is installed on a hydraulic press to produce Bulletproof plates.

Ceramic Bulletproof Plate Mold

We took the lead in obtaining the production technology of ceramic bulletproof plate molds,it is also hot pressing molding compression moulds.

Kevlar Bulletproof Plate Mold

Molded compression kevlar bulletproof plate mold can be used to produce Kevlar(Aramid) plates,armor bulletproof Plate mold design and making.

1 Cavity Bulletproof Plate Mold

Professional production a mold factory of 1 cavity Kevlar bulletproof plate mold and UHMWPE bulletproof plate mold compression moulding in Taizhou.

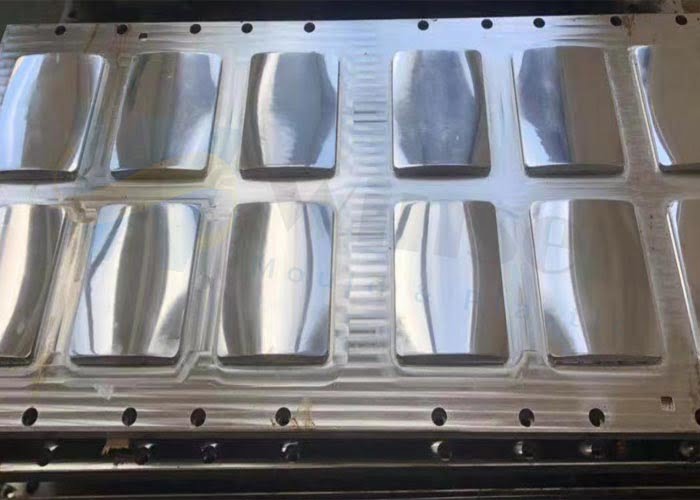

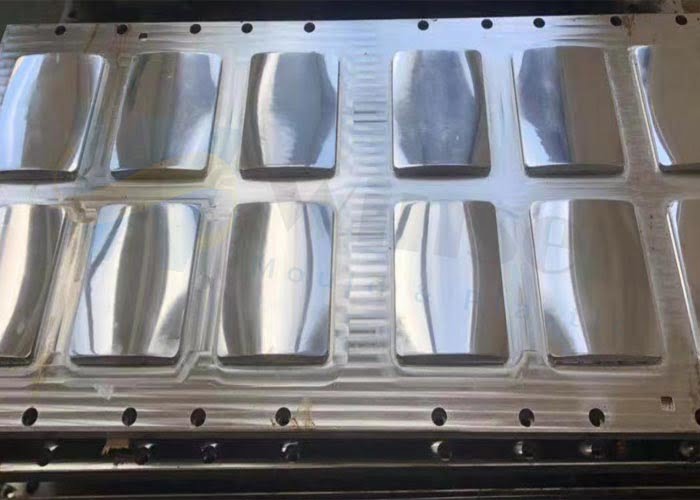

2 Cavities Bulletproof Plate Mold

2 cavities bulletproof plate mold needs 315T hydraulic press to press production,the commonly used material for has kevlar/aramid ,UHMWPE(PE).

3 Cavities Bulletproof Plate Mold

3 cavities bulletproof plate mold body armor plate mold customized design and production,we are top ballistic plate mould manufacturer in taizhou.

24 Cavities Bulletproof Plate Mold

24 cavities bulletproof plates mold with high production capacity, one mold can produce 24 bulletproof plates each shot,bulletproof plate mold is installed on a hydraulic press to produce bulletproof plates.Ballistic Plate molds professional production factory, more than 20 years of production experience.

Multi-cavities bulletproof plate mold

Multi-cavity, multi-curved and single-curved bulletproof plate mold professional manufacturer in China,as long as your hydraulic press is big enough, we can design the ballistic plate mold with the maximum number of cavities.We always have focused on the research of the military bulletproof plate compression mold.

UHMWPE(PE) Bulletproof Plate Mold

Compression Bulletproof Plate Mold

Ceramic Bulletproof Plate Mold

Bulletproof Armor SAPI Insert Plate Mold

What is bulletproof plate mould

It is a tool used to make bulletproof plate products. When the police officer encounters the threat of high-power bullets, the bulletproof insert plate is quickly inserted into the front side of the soft bulletproof vest, which can bulletproof the vital organs of the wearer’s torso, enhance protection.

We specialize in the production of various types of Bulletproof Ballistic Body Armor Plate Mould, which are generally used with various tactical bulletproof vests.Moreover,it is suitable for all kinds of body armor and tactical vests.

We have focused on the research of the molding process of the bulletproof plate compression mold, and have made fruitful explorations and results on how to improve the quality and efficiency of Bulletproof Plate mold Ballistic Armour Plate mould, increase production automation, multi-product mold interchange, and reduce the production cost of molded ballistic plates.

Why do you need bulletproof plate mold

Bulletproof plate mold is a necessary tool for the production of bulletproof plates,now the popularity of body armor in the army has been very high, and we can often see him in various blockbusters. So I believe that many friends are not very unfamiliar with body armor.

Most ballistic body armor plates are made of multi-layer aramid or polyethylene PE. Although this body armor is relatively light to wear, due to the limitations of materials and technology, according to the American standard NIJ, at most, it is only grade IIIA. That is to say, it can only protect against 9mm and .44 caliber pistol bullets. Body armor is useless when facing a rifle. In order to be able to defend against higher-level threats, we need to use bulletproof plates.

How is molding for bulletproof plate mold

Bulletproof plate mold is also compression molding,it is put the composite material into the bulletproof plate mold cavity, and under a certain temperature and pressure, the composite material is heated and circularized in the ballistic plate mold cavity to molding bulletproof plates product,offering ballistic armor plate mold chest plate mould production technology.

Application of bulletproof plate mold

Workers engaged in dangerous operations: bank currency escorts, overseas military personnel, workers in overseas armed conflict areas, bodyguards, sailors, border personnel and other related industries.

What types of bulletproof plates are there

The types of bulletproof armor insert plate materials can be roughly divided into 4 types: bulletproof steel, PE polyethylene(UHMWPE),Kevlar (aramid) , ceramic bulletproof plates (PE+alumina ceramic plate, PE+silicon carbide ceramic plate and PE+boron carbide ceramics bulletproof plates). All kinds of material models’s ballistic plate moulds can be custom made.

Ceramic bullet-proof plate, now the most widely used ceramic bullet-proof plate is the mainstream.

Ceramic bulletproof inserts plate are generally made of materials such as ceramics and polyethylene PE. Fragmentation, and it will also transmit the huge impact energy of the impact point to the surroundings to absorb the huge kinetic energy of the bullet. When the bullet passes through the ceramic layer, it has lost most of its kinetic energy. When the bullet reaches the polyethylene layer, the polyethylene consumes the kinetic energy of the bullet by stretching and wraps the bullet and shrapnel. This process has little effect on the human body and plays a very good role protective effect. The ceramic composite bulletproof plate also has certain high requirements for the production of ballistic bulletproof ceramic plate moulds due to the special application, safety and reliability requirements.

★ Steel bulletproof insert plate

It is made of special steel material, the back of the insert has a small depression after being hit by bullets, which can reduce non-penetrating damage. The anti-rust process allows the product to be immersed in water without affecting its protective performance.

★ PE + ceramic bulletproof plates

Ceramic and ultra-high molecular weight polyethylene composite bulletproof insert plate: a special process is used to combine ceramic and ultra-high molecular weight polyethylene laminate into one, which meets the requirements of level 6 in the “GA141-2010 police bulletproof vest” standard, and the weight is only 2.3kg, can defend 79 or 85 sniper rifle.

★ PE polyethylene(UHMWPE) bulletproof plates

Ultra-high molecular weight polyethylene laminated bulletproof plate: PE material, bulletproof board has the characteristics of light weight, anti-burst, anti-ricochet, etc., and can meet the requirements of level 5 in the “GA141-2010 police bulletproof vest” standard, which is better than Steel plates of the same grade are 55% lighter.It is currently the highest strength fiber in the world, with a molecular weight of more than 1.5 million. Its strength is more than ten times that of steel wire of the same cross-section. It has outstanding impact resistance, cutting resistance, UV radiation resistance, and excellent chemical corrosion resistance Features.

★ PE + alumina ceramics bulletproof plates

Alumina ceramics have the highest density among the three materials, and the bulletproof inserts plate made of alumina ceramics are much heavier in the same area. The alumina ceramics price is low. Therefore, some customers who need large-scale purchases will choose this bulletproof insert plates.

The following focuses on the PE+Alumina ballistic bulletproof plate:

The PE+Alumina bulletproof plate is a bulletproof chest plate composed of high-performance PE material and ceramic plate. It is composed of five layers of closely connected structures. From top to bottom, they are: PE woven fabric layer, PE non-woven fabric layer, oxidation Aluminum ceramic plate, PE non-woven fabric layer, PE woven fabric layer. Both ends of the alumina ceramic plate are sealed by PE nonwoven fabric. It can be a flat bulletproof chest plate or a curved bulletproof chest plate. This new composite lightweight high-performance bulletproof sheet can also be designed according to the protection level and shape of military equipment, so as to be widely used in body armor, armored vehicles, bulletproof vehicles, light tanks, bulletproof speedboats, assault boats and helicopters airplane.

PE+Alumina composite bulletproof plate, which is a new type of composite material bulletproof armor plate, has the characteristics of small bounce secondary damage and excellent bulletproof effect.

★ PE + silicon carbide ceramics bulletproof plates

The density of silicon carbide ceramics is much lower than that of alumina, and it is not even heavy compared to polyethylene PE. Its price is relatively expensive, 4 to 5 times that of alumina ceramics, but its lighter weight can bring a better wearing experience and reduce physical consumption. If it is a customer with sufficient funds after all, it is recommended to choose this kind of plug plate.

★ PE + boron carbide ceramics bulletproof plates

The boron carbide price is quite expensive, it is 8 to 10 times of silicon carbide. Also because of its high value, we generally only use this material on the bulletproof inserts of NIJ IV. But relative to such a high price, its density is limited than that of silicon carbide. Occasionally, some local customers choose to buy this kind of plug.

Differences between ceramic bulletproof inserts plate and other material's bulletproof plates

Now the most widely used and mainstream is the ceramic bulletproof plate. Let’s introduce the principle of ceramic ballistic inserts plate and the differences between them.

Ceramic bulletproof inserts plate are generally made of materials such as ceramics and polyethylene PE. Fragmentation, and will also transmit the huge impact energy of the impact point to the surroundings to absorb the huge kinetic energy of the bullet. When the bullet passes through the ceramic layer, it has lost most of its kinetic energy. When the bullet reaches the polyethylene layer, the polyethylene consumes the kinetic energy of the bullet by stretching and wraps the bullet and shrapnel. This process has little effect on the human body and plays a very good role for protective effect.

Classification of bulletproof plate molds

Bulletproof Front Plate

Bulletproof Side Plate

Bulletproof Back Plate

There are two types of bulletproof plate mould: front plate and side plate bulletproof ballistic body armor inserts moulds. The front plate will be protect the front and back of chest to avoid human body, and the side plate can be protection for side of human body. The cut angle normally protects the front of the chest and the square protects the back.

What steel is used for bulletproof plate molds

What kind of steel to use to make bulletproof ballistic body armor plate mold? We often used P20 and H13 steel to process and production bulletproof ballistic body armor plate mold.

How to heat the bulletproof plate mold

What are the heating methods of bulletproof ballistic body armor plate molding? For the heating of the bulletproof plate molding, it has 3 heating methods like the bulletproof helmet mould and bulletproof shield mould: oil, electricity, steam ect. heating methods.We will do the heating of the plate mould according to the customer’s requirements.

How many cavities can the bulletproof plate mold make?

What is the number of cavities in the compression bulletproof plate moulding? For the production of bulletproof plate moulds, our technology is very mature and far ahead, from 1 cavity bulletproof plate molds to the largest 36 cavities bulletproof plate molds. Effectively help you increase production many times.

The difference between curved and flat bulletproof plate

What is the difference between the curved bulletproof plate and the flat bulletproof plate? With the rapid progress of the bulletproof industry, various types of bulletproof equipment emerge in an endless stream, and there are more and more choices when we choose to buy bulletproof insert plates, making it difficult to choose. When most of the plates are selected, the first choice is the protection level, material and price. From the perspective of materials, the mainstream bulletproof plates include ceramic plates, PE plates and steel plates. From the perspective of defense level, the United States NIJ standards, German standards, Russian standards and other standards can be seen in the market. However, not many people pay attention to the shape of the bulletproof plate, but they do not know that the shape is also one of the factors that greatly affects the experience of the bulletproof plate. From the perspective of appearance, the shape of the plate is mainly divided into two categories: curved plate and flat plate. There are various differences such as single-curved, multi-curved, and ASC chamfering. The use of an inappropriately shaped insert will affect the wearer’s range and agility for tactical movements, as well as the actual protective effect.

Single curved bulletpoof plates mold

Multi-curved bulletpoof plates mold

①. Curved bulletproof plate

As the name suggests, the curved plate is a plate with a curved surface, which is designed according to the contour of the human chest. Therefore, the curved plate fits the human body better and is more comfortable to wear. At present, the plates used by individual soldiers are mainly curved plates. With the advancement of technology, there are usually two different classifications of curved inserts: single curved inserts plate and multi-curved inserts plate.

1) Single curved plates

A single-curved plate is a plug-in plate with only one arc that fits the curve of the human chest. It can be imagined as a rectangular plate cut from a piece of pipe. Compared with the multi-curved plate, the single-curved plate is simpler to make and the cost is lower.

2) Multi-curved plates

Multi-curved plates have additional curves along the length of the plate and are often chamfered on both sides of the upper edge.

Because the curved insert plate has a curvature, it can better fit the body surface, so it can provide more protection to the wearer than the flat insert plate. In addition, compared with the single-curved insert plate, the cut corners on both sides of the multi-curved insert allow the wearer to have both arms unimpeded during tactical activities, allowing the wearer to use weapons such as guns and perform various tactical actions more freely and flexibly. There is also a theory that when the bullet touches the insert plate, its curved surface structure will cause the bullet to deflect at an angle, thus greatly reducing the penetration force of the bullet to the insert plate.

The production process of curved inserts plate is more complicated, and they are all made with uniform specifications and standards at present. Because everyone’s body shape is different, it cannot perfectly fit the body of each wearer. In addition, since the curved surface structure will deflect the bullet, the direction of the deflection is random, which may bring secondary damage to ourselves and our comrades.

Flat bulletpoof plates mold

②. Flat Bulletproof Plate

The flat plate is just a flat plate-like structure, the production process is simple, and the price is relatively cheap, so many people think that the protection effect of the flat plate is not as good as that of the curved plate. But not necessarily, the plane structure will not involve the problem of the uncertainty of the deflection direction of the bullet. Moreover, its structure is simple, the production process is also simple, and the price is cheap, which is also a good choice for some specific usage scenarios. For example, most of the shields of the current high defense level, such as NIJ III and NIJ IV, are of flat structure, and the armor modules installed on Jeep, Hummer and other vehicles are also of flat structure. But for individuals, the comfort of wearing a flat plate and a curved board is indeed much different.

Chamfered bulletpoof plates mold

③. Chamfered Bulletproof Plate

We can notice that some bulletproof inserts plate are missing a piece on the left and right sides of the top, while others are not. In fact, the missing part is called the SC cut angle, which is designed to facilitate the user to smoothly perform standard shooting actions after wearing the insert plate. If there is no chamfer, it will hinder the shooting action to some extent.

In addition, at present, the cutting angle of some inserts plate is asymmetrical. We call this type of ASC cutting angle. This is because the movement range of the left and right arms is different when shooting. Therefore, the size of the cutting angle is adjusted separately. Better fit. However, there is a problem with this kind of corner cutting. It is necessary to distinguish between the left hand and the right hand. If it is reversed, it will have a very bad experience.

Different inserts have their own functions. Therefore, we make bulletproof insert molds according to customer requirements and designs. It is recommended that customers fully understand the conditions and conditions of their use scenarios when choosing a design, according to their actual situation and combat needs. A reasonable choice for the insert plate structure to produce the mold, because once the mold production is complete, the design is difficult to modify.

The difference between the performance of bulletproof insert armor plates and bulletproof vests

What is the difference between the bulletproof performance of bulletproof inserts armor plate and bulletproof vests(Clothes)? In fact, regardless of the bulletproof plate or the bulletproof vest, the purpose is to be able to prevent bullets, but the protection level of the bulletproof plate and the bulletproof vest is somewhat different. Because most of the bulletproof vests are soft, the main material is PE or aramid, so the protective ability is limited, the highest level can only reach NIJ IIIA level, that is to say, if you only wear the bulletproof vest, it can only withstand 9mm bullets and more Pistol threat. The materials of the bulletproof inserts are different, most of them are made of ceramic and PE, so the bulletproof inserts are hard, but the level that the bulletproof inserts can reach is very high, up to NIJ IV level, armor-piercing bullets and rifles Basically can resist. Therefore, the choice of bulletproof vest or bulletproof insert needs to be selected according to your different needs and combat environment.

What are the processing of the surface of the bulletproof plate

What are types of surface processes of bulletproof plates? There are many surface processes for bulletproof inserts plate, which are generally divided into two categories: polyurea coating and tarpaulin outer layer.

The outer layer of the tarp is a layer of waterproof fabric wrapped around the surface of the bulletproof insert plate. It has the characteristics of simple processing and low price.

The polyurea coating is to spray polyurea evenly on the surface of the bulletproof insert plate. The polyurea coating will bring extra weight, which is about 200g heavier than the outer layer of the tarpaulin. But it can also play a certain defensive effect, and the bullet hole after the bullet is shot is smaller than the bullet hole of the bulletproof insert covered with cloth as the surface. However, the price of the board with polyurea coating will also be more expensive than the board with the outer layer of tarpaulin. The specific choice can only depend on personal needs.

Bulletproof plate mold can produce various types of bulletproof plates

Taizhou Huangyan professional bulletproof plate mould manufacturer, supplying various specifications and grades of bulletproof chest insert moulds, UHMWPE(PE) and Kevlar (aramid) ballistic chest insert plates moulding , ceramic bulletproof plates compression molding.

Professional bulletproof product mold manufacturer and solution provider.

How to wear bulletproof plate correctly

As an indispensable bulletproof equipment in military activities, bulletproof inserts plate have been widely used in the military, security agencies and defense departments, and have saved countless lives. But we also need to pay attention to how it is used in the process of using the bulletproof insert, and wear the bulletproof insert correctly in order to truly exert its protective ability.

According to the type of protection, bulletproof plates can be divided into two types: STA boards and ICW boards.

The STA insert can be used independently. It can be installed on the chest of a tactical vest or body armor without bulletproof capability. The back and side pockets can provide comprehensive protection for the body; while the ICW insert cannot be used independently. , it needs to be used with NIJ IIIA body armor. No matter what kind of plug-in board, it is very important to place the position and fix it firmly when in use. We can adjust the position of the flap by adjusting the Velcro on the tactical vest or body armor.

Contact Us For More Technology

The bulletproof plates produced by the bulletproof plate mold is widely used in bulletproof armor, such as the protection of vehicles and ships, as well as the protection of civilian safes and cash transport vehicles, etc.

The evolution history of the US SAPI series bulletproof plate

the US military began to use a variety of bulletproof equipment for individual soldiers, from the small-scale trial of M9152 in the Korean War to the large-scale distribution of M1955 and M1969 in the Vietnam War. In fact, these bulletproof vests can’t prevent the direct attack of bullets.

It was not until the emergence of Kevlar materials in the 1980s that the later PASGT vests had certain ballistic resistance, but they were only limited to the penetration of projectiles equivalent to 9mm caliber pistols at a certain speed and angle. Since the birth of rifled rifles and bullets, the performance of guns has been far beyond the development of protective equipment.

Many bullets are difficult to resist even with a certain thickness of steel plate. In addition, the load that soldiers can bear is limited, and too thick bulletproof equipment will only wear out soldiers. The physical fitness and maneuverability of a person are meaningless for the improvement of battlefield protection.

In order to obtain better bulletproof effect, lightweight and strong bulletproof materials have always been the goal of human exploration. The OTV that appeared after PASGT became the first official bulletproof vest with real ballistic performance in the US military, and the reason for this ability was the emergence of SAPI-Small Arms Protective Insert small arms protection plate. On the basis that soft Kevlar materials can only achieve limited protection, OTV uses hard silicon carbide ceramic plates to obtain higher protection capabilities.

According to the requirements of the military, a standard size SAPI must have the ability to effectively withstand the impact of a 7.62mm caliber M80 projectile flying at a speed of 841 meters per second, and each SAPI must be able to withstand three such impacts to be considered qualified. This also means that the OTV vest equipped with SAPI can resist the attack of the 7.62×39mm projectile fired by the AK47 rifle, which is definitely a qualitative improvement for individual soldier protection!

During the war in Afghanistan that began in 2001 and the Iraq war that began in 2003, a large number of individual bulletproof vests based on OTV were distributed to every US soldier deployed on the front line. This also greatly reduced the probability of soldiers being directly hit by bullets and dying in these two wars. However, the opponents in the anti-terrorism war are not a group of rabble. Their weapons are not only the old AK47 rifles. Snipers use a lot of Russian-made SVD sniper rifles with a caliber of 7.62×54mm, and the projectiles are more penetrating.

In addition, the anti-US military began to use armor-piercing projectiles to attack the US military’s strong protection capabilities, so the US military began to use the boron carbide ESAPI enhanced plug-in type produced by Ceradyne, BAE Systems and ArmorWorks in May 2005. Enhanced Small Arms Protective Insert for small arms protection plate, this ESAPI can resist attacks equivalent to .30-06 caliber M2 steel core or tungsten core armor-piercing bullets, but ESAPI is more expensive, and each piece sells for $600.

In the following years, the threats faced by the U.S. ground forces did not decrease, so the U.S. Army proposed the concept of the next-generation shield, XSAPI. The Army required this new generation of hard shields to be more flexible, convenient and systematic. It is more flexible, has a larger protective area, and cannot increase the weight. Because of the end of the war on terrorism, XSAPI has not officially appeared in the US military’s sequence, but the design of XSAPI has not been stagnant. Once the US military faces new threats again, this next-generation light weapons shield will be quickly distributed and put into use.

Initially, the performance of the SAPI board used in bulletproof vests represented by OTV has not been rated by NIJ, the National Institute of Justice, because it is designed and tested in accordance with military standards.

The standards formulated by Fang are not equivalent to the NIJ test standards, but after a series of successes on the battlefield, the civilian and law enforcement markets also favored SAPI, so the NIJ also conducted a series of standard evaluations. Generally speaking, the standard SAPI board has the ballistic resistance of class III or above. The local fragmentation of the hard ceramic layer of the SAPI board is used to offset the kinetic energy of the invading projectile, passivate the penetration force of the projectile, and then use a larger area of SAPI to buffer Layers to spread the impact, block projectile fragments, and minimize the potential for lethal damage.

That is to say, SAPI does not guarantee that the user will be unharmed, but can only guarantee that the user will not be fatally injured. Secondary injuries are very common. In order to reduce such injuries, the US military generally requires that bulletproof vests must be combined with soft and hard, that is, use hard SAPI boards in addition to the soft protective layer, which can effectively reduce the occurrence of secondary injuries.

OTV is the U.S. military’s first tactical vest with real bulletproof capability. It is also benefits from SAPI plates. Later, the IOTVMTVIMTVSPCSPCS and other tactical bulletproof vests that the US military replaced all use SAPI/ESAPI boards. Get enough bullet resistance. In order to meet different needs, SAPI is designed into two types: frontal type and side type. Front and rear chest use frontal type, and two ribs use side type. In terms of appearance, SAPI’s unique cut-angle trapezoid has also become one of its iconic features. The side-type SAPI uses less chamfered design and is smaller in size.

Carefully do each bulletproof plate mold,technology creates the future !

WHO WE ARE

WS is committed to providing customers with professional protective equipment mold solutions, a leading manufacturer of bulletproof insert molds.

We are differentiated by our technology and professional value, and therefore bring our partners their customer viscosity and product reliability, and even bring cost savings and added value to our customers.

It is an honor for WS to meet you. Thank you for visiting our website during your busy schedule. At the same time, I hope your attention, we will continue to provide you with valuable information to meet our mutual needs and seek common development.

We look forward to creating a more brilliant tomorrow together with our customers!