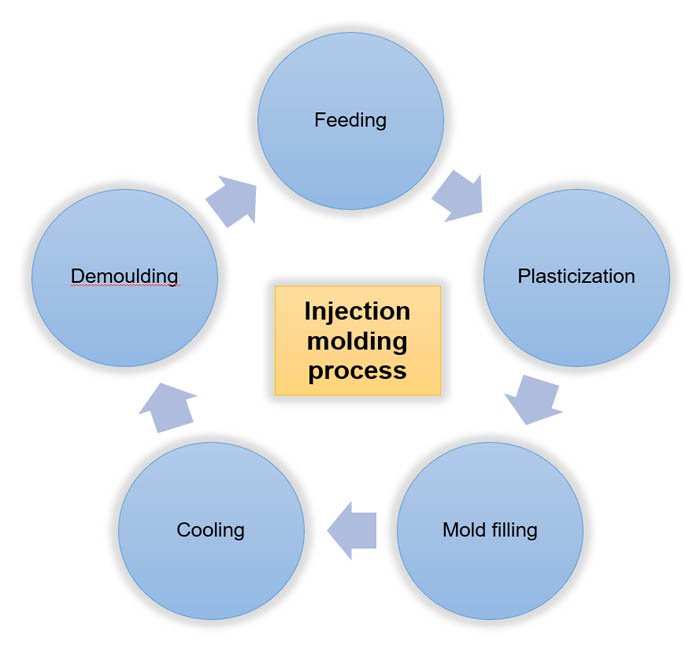

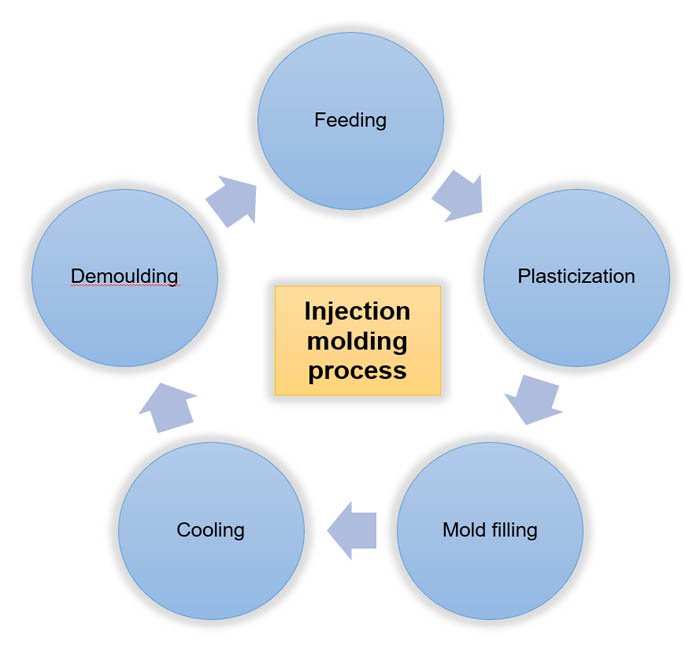

For plastic products, what are the 5 main steps of injection moulding process ? It is very important to choose which processing and molding method. Because different processing and molding methods not only have a great impact on the quality of plastic products, but also have great differences in production costs. At present, in the field of plastic processing, injection molding technology is relatively cost-effective, and there are many injection molding manufacturers in taizhou that use this process for processing. It is not very difficult to understand the injection molding process. The following editor will introduce to you the process of injection molding in Taizhou.

Table of Contents

ToggleWhat is the injection moulding process?

1. Feeding

Plastic raw materials are generally made into granular objects in advance for processing plastics. During injection molding, these particles are added to the hopper of the injection molding machine, and then heated and stirred under the action of the plunger or screw.

2. Plasticization

Plastic raw materials are generally made into granular objects in advance for processing plastics. During injection molding, these particles are added to the hopper of the injection molding machine, and then heated and stirred under the action of the plunger or screw.

What is the injection moulding process

3. Mold filling

When the plastic raw materials are basically plasticized, we can fill these melts into a mold through pressure, and the plastic raw materials will form a specific shape in the mold.

4. Cooling

After a period of heating and pressure-holding measures, the basic conditions for the molding of plastic raw materials have been achieved. At this time, we can solidify it by cooling to form a plastic product with a stable state.

5. Demoulding

The plastic product after molding is still in the mold, so we still need to release it from the mold through the demoulding operation. In order to release the mold smoothly, we generally need to add a special mold release agent to the plastic raw materials.

The above is the process of injection molding. According to this process, the quality and effect of plastic molding can be guaranteed to a great extent. With the breakthrough of material processing technology, many new plastic materials have begun to appear on the market, and the plastic processing and molding process has become more marketable. As a very common and mature technology, injection molding may have broader development and application prospects in the future. For more information, you can continue to follow us.

Process Flow

The injection molding process mainly includes 6 stages of mold closing – filling – pressure holding – cooling – mold opening – demoulding. These 6 stages directly determine the molding quality of the product, and these 6 stages are a complete continuous process. This chapter focuses on the four stages of filling, pressure holding, cooling and demoulding.

Several common injection molding processes

Mold injection molding is used in many plastic products, and the most common process in plastic molding is mold injection molding, and plastic is a very common material in life, and the products made of it are also particularly popular. In the mold injection molding process, what are the most common injection molding processes?

1. Injection molding

Injection molding also called injection molding, and the factors that affect the quality of injection molding are injection pressure, injection time and injection temperature.

2. Insert injection molding

It refers to a molding method in which a pre-prepared insert of a different material is placed in an injection mold, and then resin is injected, and the molten material and insert are joined and solidified to form an integrated product.

Mold injection molding is used in many plastic products, and the most common process in plastic molding is mold injection molding, and plastic is a very common material in life, and the products made of it are also particularly popular. In the mold injection molding process, what are the most common injection molding processes?

3. Two-color injection molding

It is a special injection molding process in injection molding, which refers to the method of injecting two different colors of plastic into a special two-color mold to make it shape.

In addition, there are micro-foaming injection molding process and nano-injection molding process, etc., which are more commonly used technical processes in mold injection molding. They also have different characteristics and performance, but as long as the mold injection molding will be through the molten raw material, after a series of specified operations such as pressurization, injection, cooling, detachment, etc., to produce a certain shape of the finished product. crafting process.