In the realm of military equipment, the importance of reliable, durable, and high-performance gear cannot be overstated. Bulletproof Ballistic Military Helmet Molds are stand out as critical components in the production of helmets that save lives on the battlefield. Recently, we had the privilege of manufacturing and exporting 2 such bulletproof helmet molds to Russia, showcasing our expertise in precision engineering and our commitment to delivering top-notch products. This blog delves into the intricacies of these molds, their significance, and the process behind their creation.

Table of Contents

ToggleCustom Bulletproof & Ballistic Military Helmet Molds Exported to Russia

Bulletproof and Ballistic Helmets are very important,but it needs made by High-Quality Bulletproof & Ballistic Military Helmet Mold.Military helmets have evolved significantly over the years, from simple metal shells to advanced composite materials designed to withstand ballistic impacts. The modern Bulletproof Helmet and Ballistic Helmet are engineered to provide maximum protection against bullets, shrapnel, and other battlefield hazards. These helmets are not just pieces of equipment; they are lifelines for soldiers in combat zones.

The production of these helmets relies heavily on the quality of the molds used in their manufacturing process. A Military Helmet Mold must be meticulously designed and crafted to ensure that the final product meets stringent safety standards. This is where our expertise comes into play.

The Role of Military Helmet Molds in Helmet Production

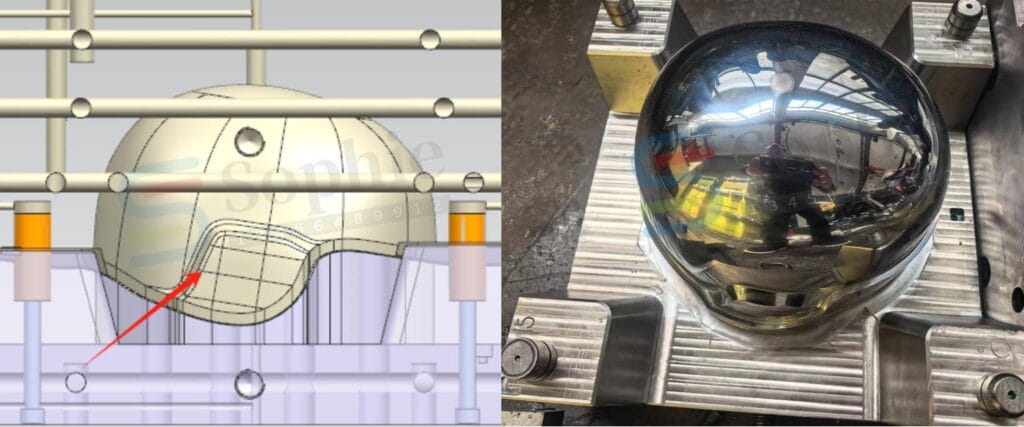

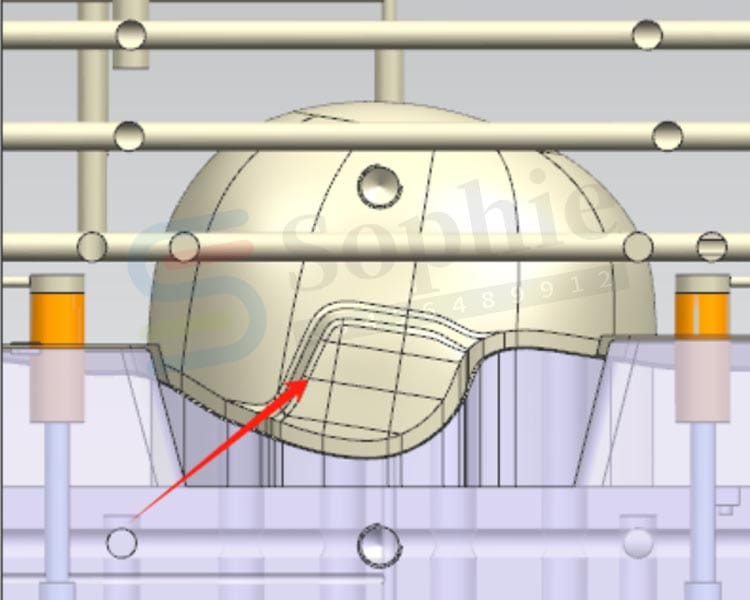

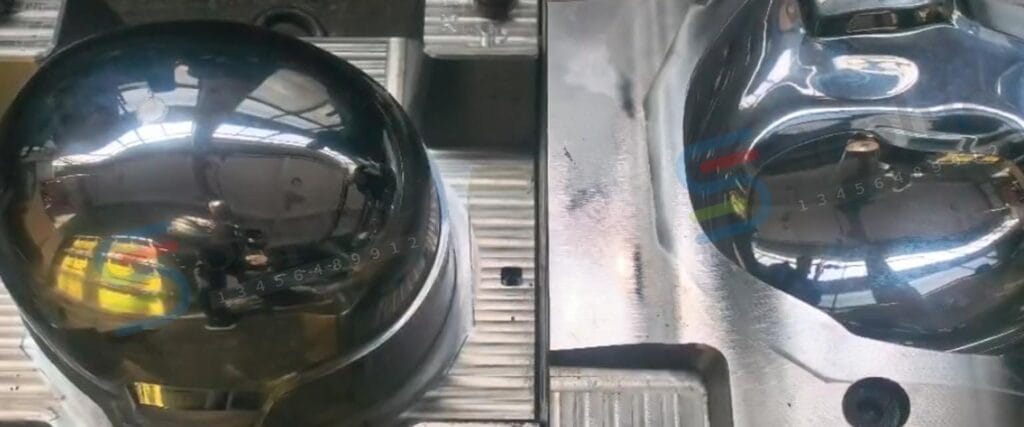

The Bulletproof Helmet Mold and Ballistic Helmet Mold are crucial in the production process. These molds are used in a compression molding technique, where composite materials are heated and pressed into the desired shape. The precision of the mold directly impacts the helmet’s structural integrity, weight, and overall performance.

Our recent project involved the creation of two such molds, both of which were exported to Russia. These molds were designed to produce helmets that meet the rigorous demands of modern military operations. The process of creating these molds is a testament to our commitment to quality and precision.

The Manufacturing Process: Precision and Expertise

Creating a Military Helmet Mold is a complex process that requires a deep understanding of materials, engineering, and manufacturing techniques. Here’s a brief overview of the steps involved:

- Design and Engineering: The first step involves designing the mold using advanced CAD software. This stage requires a thorough understanding of the helmet’s specifications, including its shape, size, and the materials to be used.

- Mold Material Selection: The choice of materials for the mold is critical. High-grade steel such as H13 vacuum quenching treatment can make the hardness reach above 50HRC hardness,therefore, the bulletproof helmet mold is more durable.

- CNC Machining: Once the design is finalized, the mold is crafted using CNC machining. This process ensures that every detail of the mold is very precision to ensuring the quality of the final helmet

- Heat Treatment: The mold undergoes heat treatment to enhance its strength and durability. This step is crucial for ensuring that the mold can withstand the rigors of repeated use.

- Quality Control: Before the mold is shipped, it undergoes rigorous quality control checks. This includes inspections for dimensional accuracy, surface finish, and overall integrity.

Exporting to Russia: A Milestone Achievement

The export of these two Bulletproof Helmet Molds and Ballistic Helmet Molds to Russia marks a significant milestone for our company. It not only underscores our capabilities in precision engineering but also highlights our ability to meet the demands of international clients.

Russia, with its vast military infrastructure, has stringent requirements for military equipment. The fact that our molds have been chosen for use in their helmet production is a testament to the quality and reliability of our products.

Why Choose Our Ballistic Helmet Molds?

When it comes to Military Helmet Molds, precision and reliability are paramount. Here are a few reasons why our molds stand out:

- Advanced Technology: We utilize state-of-the-art technology in the design and manufacturing of our molds, ensuring the highest levels of precision and quality.Our latest innovative technology can increase mold production efficiency by 10% compared to traditional technology.

- Expertise: Our team of engineers and technicians bring years of 20 years experience and expertise to every project, ensuring that each mold meets the exact specifications required.

- Quality Assurance: Rigorous quality control processes are in place to ensure that every mold that leaves our facility is of the highest standard.

- Customer-Centric Approach: We work closely with our clients to understand their needs and deliver products that exceed their expectations.

Conclusion

The production of Bulletproof Helmets and Ballistic Helmets is a critical aspect of modern military operations. The molds used in their production play a pivotal role in ensuring that these helmets provide the necessary protection to soldiers on the front lines. Our recent export of two Military Helmet Molds to Russia is a testament to our commitment to quality, precision, and excellence in engineering.

As we continue to innovate and push the boundaries of what’s possible in Military Ballistic Helmet Mold manufacturing, we remain dedicated to providing our clients with products that meet the highest standards of quality and reliability. Whether it’s a Bulletproof Helmet Mold, a Ballistic Helmet Mold, or any other specialized mold, you can trust us to deliver excellence every time.

For more information on our products and services, feel free to contact us. Let’s work together to create Military Bulletproof Helmet molds that make a difference.

The successful export of carbon fiber compression molding helmet molds is not only a victory for us in the field of high-end mold manufacturing, but also an important step for us to enter the international market. We look forward to cooperating with more international customers to jointly promote the development of carbon fiber composite material technology.