MICH ACH FAST PASGT Bulletproof Helmet Mould Compression Mold factory in taizhou,bulletproof Helmet Mould are made of by P20 or H13 steel,Winsen Mold manufacturing MICH ACH FAST PASGT various model Bulletproof Helmet compression mold, High Quality Anti-Impact bulletproof helmet molding maker in taizhou huangyan

Winsen has cooperated with military enterprises for a long time to explore the molding process of military molded bulletproof helmet molds. Helmets are a very common piece of equipment on the battlefield. They do not have offensive power, but have strong defensive power.

The bulletproof helmet compression mould is an important process equipment for the production of army products. The mold has become an important basic tool of the national economy. The key to the development of the compression bulletproof helmet industry is the advancement of mould technology.

The company has experienced professional military bulletproof product mould technicians, and professional and senior hardware moulds design engineers who have been engaged in design and manufacture for many years.

What is molding technology for Bulletproof Helmet Mold

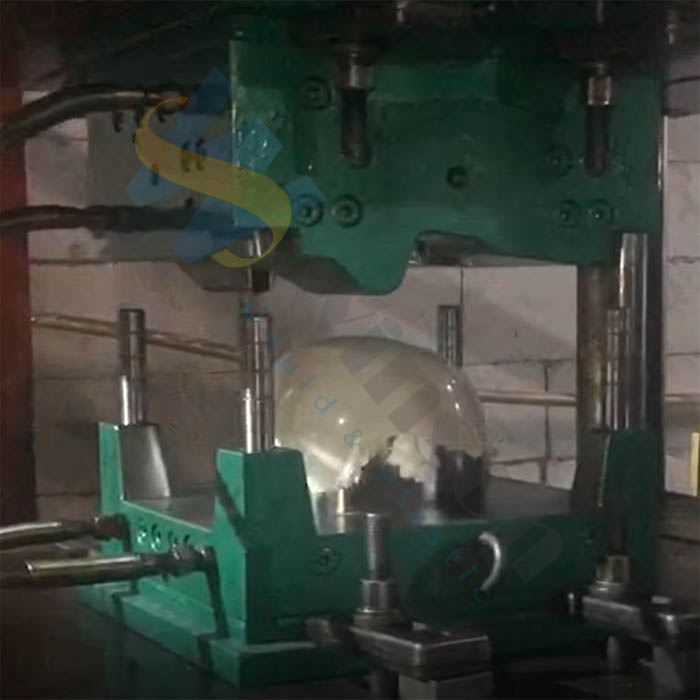

Mold compression molding is a key step in manufacturing bulletproof helmets. The process involves placing high-performance materials such as aramid or ultra-high molecular weight polyethylene (UHMWPE) into precision-designed molds and compressing them under high temperatures and pressures. This approach ensures an even distribution and density of helmet materials to provide maximum protection.

Details for Bulletproof Helmet Mould Compression Mold

Bulletproof helmet molds are a key technology in shaping modern protection. On the modern battlefield, soldiers’ personal protective equipment is crucial. As an important piece of equipment that protects soldiers’ heads from shrapnel and bullets, helmets’ design and manufacturing processes have attracted much attention. MICH (Modular Integrated Communications Helmet), ACH (Advanced Combat Helmet), FAST (Future Assault Shell Technology) and PASGT (Personnel Armor System for Ground Troops) are several types of ballistic helmets that are currently widely used. The production of these helmets is inseparable from precision mold compression molding technology.

Design Stage for Bulletproof Helmet Mould Compression Mold

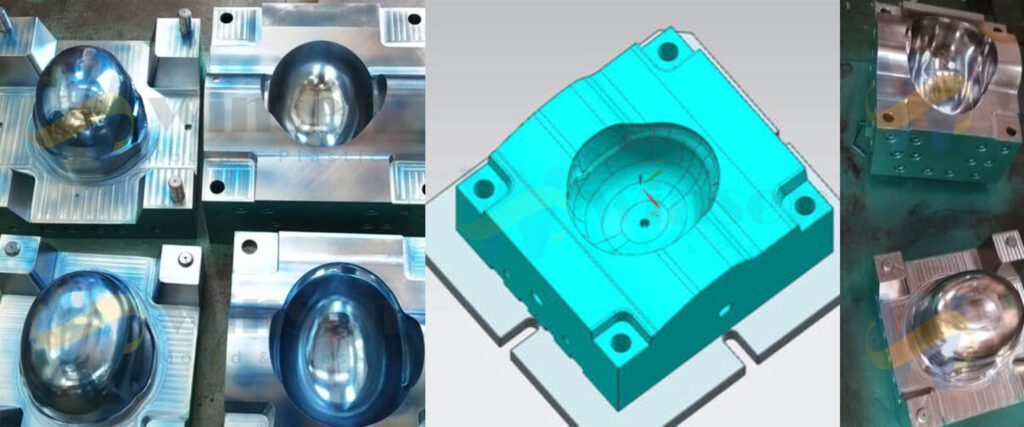

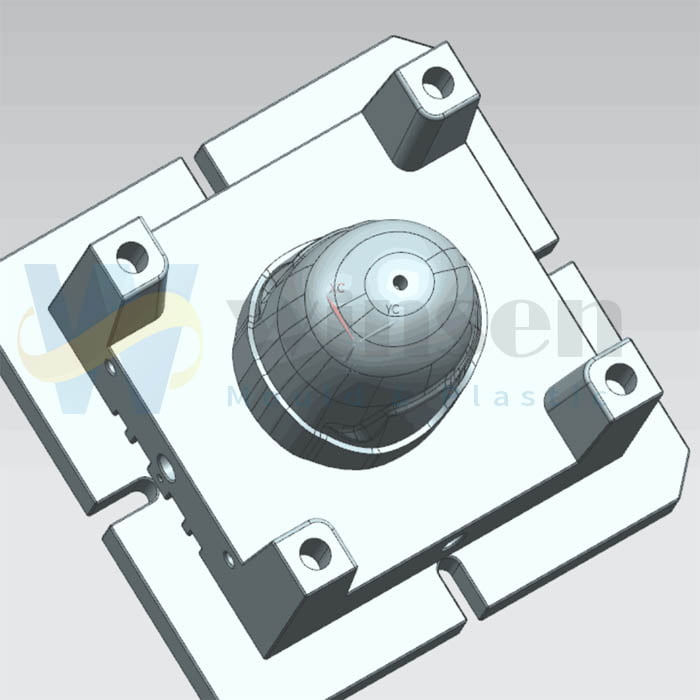

During the mold design phase, engineers use advanced computer-aided design (CAD) software to create a three-dimensional model of the helmet. These models must take into account the helmet’s protective properties, weight, comfort, and compatibility with other equipment. Designed molds go through multiple iterations and tests to ensure the final product meets strict standards.

Manufacturing Stage for Bulletproof Helmet Mold Compression Mold

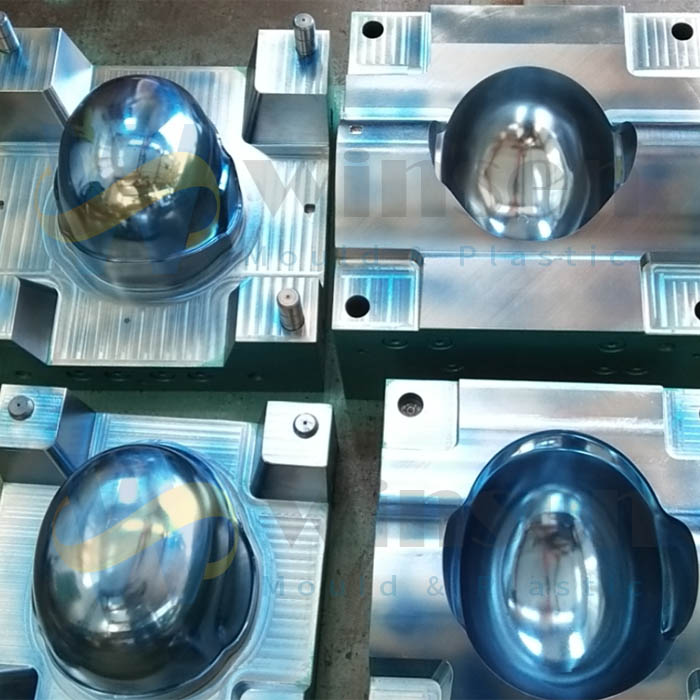

Molds are usually manufactured using high-strength steel or other high-temperature-resistant materials to withstand the high pressures and temperatures during the molding process. Precision machining ensures the dimensional accuracy and surface finish of the mold, which is crucial to the quality of the final product.

Forming stage for Bulletproof Helmet Mold Compression Mold

During the forming stage, the selected material is placed in the mold and processed at specific temperatures and pressures. This process requires precise control to ensure that the material flows evenly through the mold, resulting in a uniform helmet shell. The molded helmet needs to be cooled and then removed from the mold

MICH, ACH, FAST and PASGT ballistic helmet mold compression molding technology is a key innovation in the field of modern personal protective equipment. Through a sophisticated design and manufacturing process, these helmets provide soldiers and law enforcement officers with the necessary protection while maintaining comfort and functionality. As materials science and manufacturing technology continue to advance, we can expect these helmets to become lighter and stronger in the future, better protecting those on the front lines keeping us safe.

Threats to the head continue to increase in modern warfare and policing operations. High-performance ballistic helmets can effectively reduce fatal injuries and have become part of the standard equipment of soldiers and law enforcement officers. MICH, ACH, FAST and PASGT helmets not only provide ballistic protection, but also consider many aspects such as comfort, communication integration and the installation of additional equipment.