3D Printing & 3D Scanning

Personalized on-demand customization to quickly make any complex product Save time and money and improve business competitiveness No need to process machine tools and molds, accurate and fast

3D Printing & 3D Scanning Service for Metal & Plastic Material Products

3D scanning and 3D printing have been widely used in various industries, greatly shortening the development process of new products.In terms of industrial design, 3D scanning and 3D printing can provide easier access to product development and can be used to quickly spot errors in existing products or inform decisions for future prototyping to create new or improved designs.

3D Printing Plastic Part

3D Printing Metal Part

3D Scanning Plastic Part

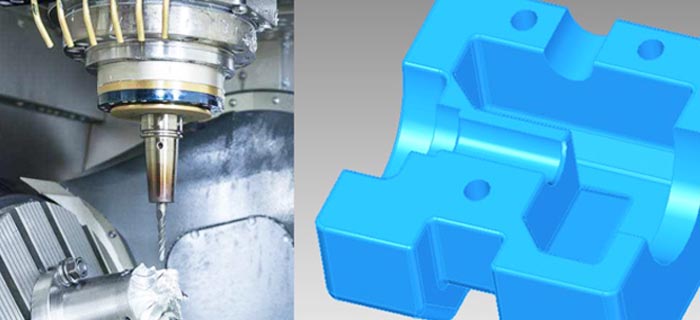

3D Scanning Metal Part

What is 3D Printing

3D printing (3DP) is a kind of rapid prototyping technology, also known as additive manufacturing. It is a digital model file based, using powder metal or plastic and other bondable materials to construct layer by layer printing. object technology.

3D printing is usually achieved using digital technology material printers. It is often used to make models in the fields of mold making, industrial design, etc., and then gradually used for the direct manufacturing of some products. There are already parts printed using this technology. The technology has applications in jewelry, footwear, industrial design, architecture, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, firearms, and more.

In general,our injection molds will last well over 100,000 shots. Moreover, wsmcmold offers a lifetime warranty for any injection molds which you purechased from us.

What are the main 3D Printing technologies

There are many technical principles of 3D printing on the market, but there are three mainstream and common types, namely: FDM, SLA, and SLS, which are described in detail below:

1. FDM: It is the abbreviation of ‘Fuseddepositionmodeling’, fused deposition modeling technology.

The 3D printing FDM fusion lamination molding technology is to heat and melt the filamentous hot-melt material, and then the three-dimensional nozzle is applied to the worktable according to the cross-sectional contour under the control of the computer, just like squeezing toothpaste; , the machine table drops a height (ie layer thickness) and then shapes the next layer until the entire solid shape is formed.

2. SLA: It is the abbreviation of the full name ‘Stereolithography’, a photosensitive resin selective curing molding technology. The principle of this 3D printing technology generally uses photosensitive resin materials. The printing process is as follows:

①The machine emits a laser beam and scans along the liquid surface according to the three-dimensional cross-sectional profile in the computer;

②The photosensitive resin will quickly solidify when it encounters a specific wavelength of light, thus completing a layer of cross-section slices; ③The worktable is lowered to the height of one layer of cross-section layer thickness, and then another layer of cross-section is cured.

3. SLS: It is the abbreviation of ‘Stereo Lithography Apparatus’, powder material selective laser sintering molding technology.

The type and principle of 3D printing technology of SLS is very similar to SLA. The biggest difference is the material, one is liquid and the other is solid (powder). The forming principle and process of this technology are as follows:

①A layer of powder is laid on the upper surface of the molded part and heated to a temperature just below the sintering point of the powder;

②The system controls the laser beam and scans the powder layer according to the three-dimensional cross-sectional profile in the computer, so that the temperature of the powder rises to the melting point, sintering and bonding with the formed part below;

③ After the completion of one layer, the worktable is lowered by one layer of thickness, and the spreader rolls spread a layer of uniform and dense powder on it, and sinter a new layer of cross-section until the entire model is completed.

3D printing applications

The application fields of 3D printing are very wide, including international space, naval ships, aerospace technology,medical field, housing construction, automobile industry, electronics industry,

submarine paving, etc.

Common materials for 3D printing include nylon glass fiber, durable nylon material, gypsum material, aluminum material, titanium alloy, stainless steel, silver-plated, gold-plated, and rubber-like materials.

Which materials of parts can be 3D printed

3D printing has rapidly expanded from a niche market to a mainstream trend today and is growing at an astonishing rate. The real advantage of 3D printing technology lies in its printing materials, which can well mimic the mechanical or thermal properties of plastic and metal materials. What are the 3D printing materials? At present, 3D printing materials mainly include engineering plastics, photosensitive resins, rubber materials, metal materials and ceramic materials, etc. Below we analyze the classification of 3D printing materials respectively.

1. Polymer material

As the most widely used type of 3D printing materials, polymer materials account for more than 90% of commercial 3D printing materials. They are used in FDM equipment and are plastics with excellent strength, impact resistance, heat resistance, hardness and aging resistance. . Common ones are acrylonitrile-butadiene-styrene copolymer (ABS), polyamide (PA), polycarbonate (PC), polyphenylene sulfone (PPSF), polyether ether ketone (PEEK) and so on.

ABS material has good hot melt and impact strength, and is the preferred engineering plastic for fused deposition modeling 3D printing process, and its application range covers almost all daily necessities, engineering supplies and some mechanical supplies. ASA, the newly developed FDM material from Stratasys, a 3D printing industry leader, is UV resistant, more durable, and has an impressive surface finish for prototype and final applications in outdoor/sports, appliances, automotive, toys, and more. product. Compatible with all FDM systems, including Stratasys’ own Fortus range of machines: Fortus 360mc, 400mc, 380mc, 450mc and 900mc. This ASA material is expected to replace ABS material.

PA, polyamide, commonly known as nylon, usually referred to as “white plastic”, is an engineering plastic with excellent performance, with excellent mechanical properties, outstanding corrosion resistance, oil resistance, heat resistance, high modulus and other advantages , are widely used in electronic and IT equipment, auto parts, mechanical equipment, medical equipment and LED lighting and other fields. However, it requires a higher printing temperature than other plastic materials, making it more professional to use. Stratasys offers highly customized nylon material options for different printing methods and production requirements. Common combinations include: carbon fiber nylon, glass fiber nylon, aluminum mixed nylon, flame retardant nylon, mineral fiber nylon, etc.

The photosensitive resin has fast curing speed and excellent surface drying performance. After molding, the product has a smooth appearance and can be in a transparent or translucent frosted state. It is a commonly used filling and restorative material in dentistry.

2. Metal materials

3D printing metal materials have a small market share at this stage, but the expansion rate is the fastest. These materials exist in the form of metal powders, metal foils, and metal wires. Common metal materials include titanium alloys, stainless steel, cobalt-chromium alloys, and aluminum alloys. Gold, silver and other precious metal powder materials are occasionally used to print jewelry or artwork.

3. Ceramic materials and composite materials

Ceramic materials have high strength and high hardness. High temperature resistance, low density, good chemical stability, corrosion resistance and other excellent characteristics, it has a wide range of applications in aerospace, automotive, biological, home decoration materials and other industries.

Carbon fiber material is an emerging 3D printing material, which is five times stronger than steel but only 1/3 of its weight, and has the advantages of high temperature resistance and corrosion resistance.

In addition to the above, the classification of 3D printing materials also includes colored gypsum materials, artificial bone meal, cellular biological raw materials, and food materials such as sugar.

What are the 3D printing materials? For the 3D printing industry, in fact, every material is a solution. The classification of stratasys 3D printing materials can be divided into PolyJet materials and FDM materials, pla polylactic acid materials, absplus plastic materials and nylon 12 carbon fiber materials. The specific polyjet materials can be divided into many materials, such as high temperature resistant materials, transparent materials, etc. FDM materials can also be subdivided into ABSplus, FDM nylon 6 and other materials. Using these materials, and with the appropriate 3D printer, prototypes can be produced that look, feel and operate exactly like the finished product, without the need for coloring or assembly, bringing even the most whimsical ideas to life.

It can be seen from the classification of 3D printing materials that the combination of 3D printing technology and various materials will undoubtedly bring infinite imagination to designers. Only by developing more new materials can the application field of 3D printing technology be expanded. Therefore, the focus of the next stage of 3D printing is undoubtedly how to improve 3D printing materials to create more flexible, durable and useful objects.

What is 3D Scanning

The process of 3D scanning is the process of converting a physical object into an accurate digital model. Ability to quickly and accurately capture the geometry of objects. The scanned 3D data can be used for size detection, reverse design, 3D printing, etc.

3D scanning service, fast and accurate scanning results, saving you time, effort and worry. 3D scanning can quickly obtain the complete surface of the object, verify the dimensional deviation of the scanned object and the CAD model, carry out dimensional inspection, test various problems before the parts are put into application, and correct them.

Scanned 3D data can also be reverse engineered and optimized. Innovate in structure, function, appearance, etc. It may be difficult or even impossible to measure complex surfaces using traditional measurement methods, such as calipers. 3D scanning is the most effective measurement method. It is also possible to directly carry out 3D printing, cnc processing, and casting various production applications through the data of 3D scanning.

We have advanced equipment and experienced staff, which can scan tiny parts as well as whole vehicles and even buildings, ships, airplanes, wind power equipment, etc. Formats that can be provided after reverse design are: AutoCAD, SolidWorks, Pro/E, CATIA, UG, IDEAS, Autodesk Inventor, Rhino, Revit, CAE/CAM and others

Whether it’s comparing 3D scanned data with cad models for size inspection or reverse engineering prototypes to develop new products. 3D scanning produces high-precision point cloud data that can be modeled,welcome contact us for a qute.