Prototyping Injection Molds

Rapid prototyping, excellence, injection mold prototype services

What is Prototype Injection Molds

Prototype injection molds are like “temporary tools” for making injection molded parts and are mainly used to verify product designs and conduct small-scale production.

The purpose of prototype injection molds is to help designers and engineers quickly produce product prototypes so that necessary adjustments and improvements can be made before going into mass production.

Rapid prototyping injection mold, a powerful tool for design verification! Save costs, shorten cycles, bring products to market quickly, and realize unlimited creativity.

Prototype injection molds are popular in various industries, such as automotive, electronics, medical devices, etc. They are used for product design, market testing, and production process verification

Prototype injection molds's Characteristics

Fast production time

The production time is short, and rapid prototyping technology is usually used to obtain prototype molds in a shorter time

Low Cost

Relative to permanent production molds, prototype injection molds are less expensive to make because they typically use less expensive materials and simpler manufacturing processes

Mold Material diversity

Prototype molds can be made from a variety of materials, including aluminum, mild steel, and even some high-strength plastics to meet different verification needs

Short mold life

The design life is short and is generally only used for small-scale production (usually hundreds to thousands of injection molding cycles). After the design is confirmed to be correct, it will be replaced with a durable production mold.

Flexibility

High design and modification flexibility, able to quickly adjust to meet product design changes and optimization needs

Prototype injection molds help you quickly test and optimize designs, reduce production costs, shorten development cycles, and enable innovation to be realized faster

Prototype injection mold use

Design verification

Before mass production, prototype injection molds are used for design verification to ensure that the product functions and looks as expected.

Market Testing

Produce small batches of samples for market testing and customer feedback.

Production process verification

Test and optimize the production process to determine the best injection molding parameters and processes.

The difference between prototype injection mold and rapid prototyping mold

Although prototype injection molds and rapid prototyping molds are similar in some aspects, they are not exactly the same concepts.

A prototype injection mold are a temporary mold used to manufacture injection molded parts, primarily for testing and validating product designs. This kind of mold usually has lower cost and shorter production time, and is suitable for small batch production and design verification.

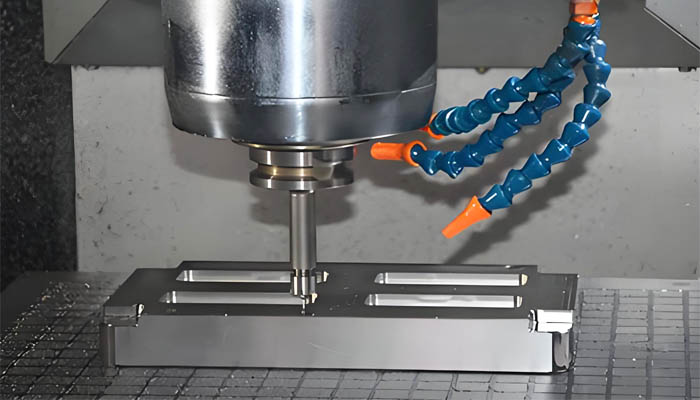

Rapid Prototyping Molds are a technology used to quickly manufacture molds or prototypes. It usually uses technologies such as 3D printing and CNC machining to go from design drawings to finished parts faster. Rapid prototyping molds can be used not only for making prototype injection molds, but also for other types of mold manufacturing

Prototyping injection molds processing

Prototype injection mold can helo you quickly verify your design, save costs, improve efficiency, and get your products to market faster

Purpose different

Prototype injection molds are mainly used for design verification and small batch production; the main purpose of rapid prototyping molds is to quickly manufacture molds or parts.

Technology different

Prototype injection molds are usually made using traditional injection molding technology, while rapid prototyping molds use advanced rapid prototyping technologies (such as 3D printing, CNC machining).

Time and Cost different

Rapid prototyping molds take less time and are less expensive to make, but may not have the durability and precision of traditional molds.

Therefore, although prototype injection molds can be made using rapid prototyping technology, the definitions and application scope of the two are slightly different.

Prototype injection molds are a temporary, lower-cost mold solution mainly used for product design verification and small batch production to ensure that the product meets the expected quality and functional standards before mass production

Injection rapid prototyping mold development trends

In recent years, the focus of manufacturing has shifted from cost and quality to time and responsiveness. Mold manufacturing is a key bottleneck restricting the development of my country’s automobile, home appliance, light industry and other industries. With the continuous advancement of rapid prototyping technology, the strength and precision of prototype parts are getting higher and higher.

Quickly bringing diversified products to the market is an important means for manufacturers to seize the market. Rapid response manufacturing has become a hot spot in international research. Rapid prototyping, rapid molding, and rapid manufacturing technologies provide advanced tools for enterprises to enhance their competitiveness. This technology is based on the layer-by-layer accumulation of materials and is considered a major breakthrough in the manufacturing field. It can manufacture a variety of sophisticated and complex molds, such as injection molds, die-casting molds and stamping molds.

Currently, this technology is widely used in automobiles, aerospace, ships, home appliances, industrial design, medical care, construction, handicraft production, and children’s toys. As technology continues to develop, its application scope is also expanding. In the automotive and home appliance manufacturing industries, mold-formed parts account for 50% to 70% of manufacturing man-hours. Rapid prototyping technology has gradually penetrated into the field of rapid mold manufacturing. Manufacturing various simple and economical rapid molds based on rapid prototyping methods has become a hot issue.