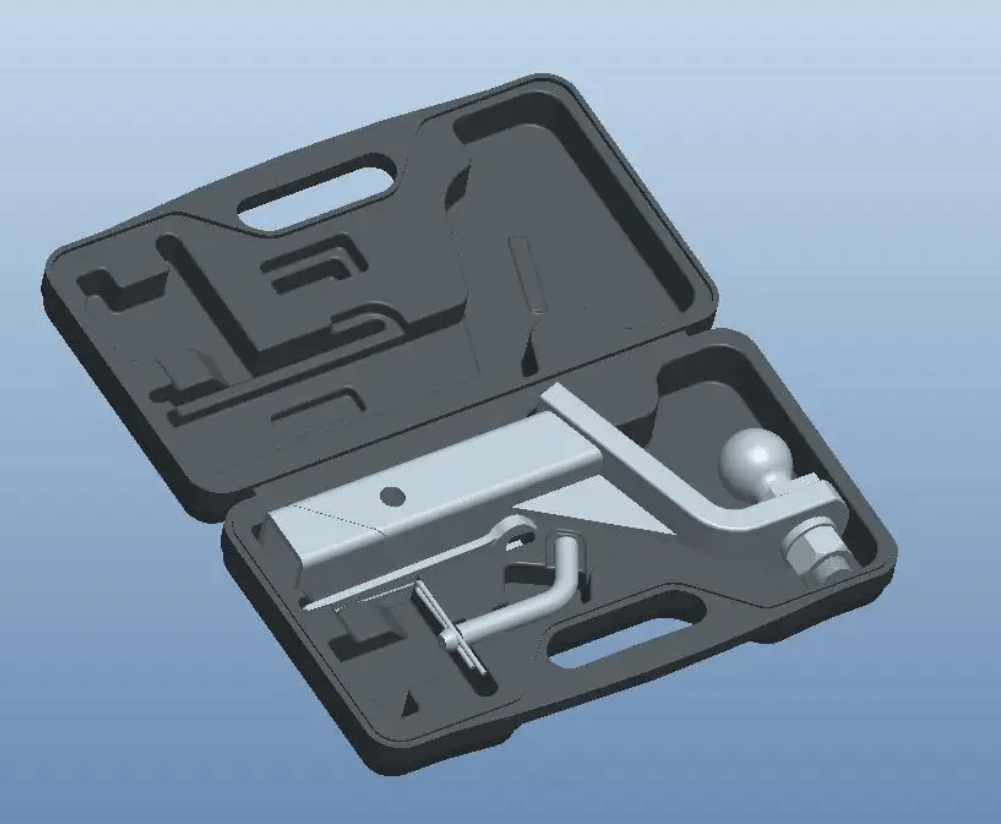

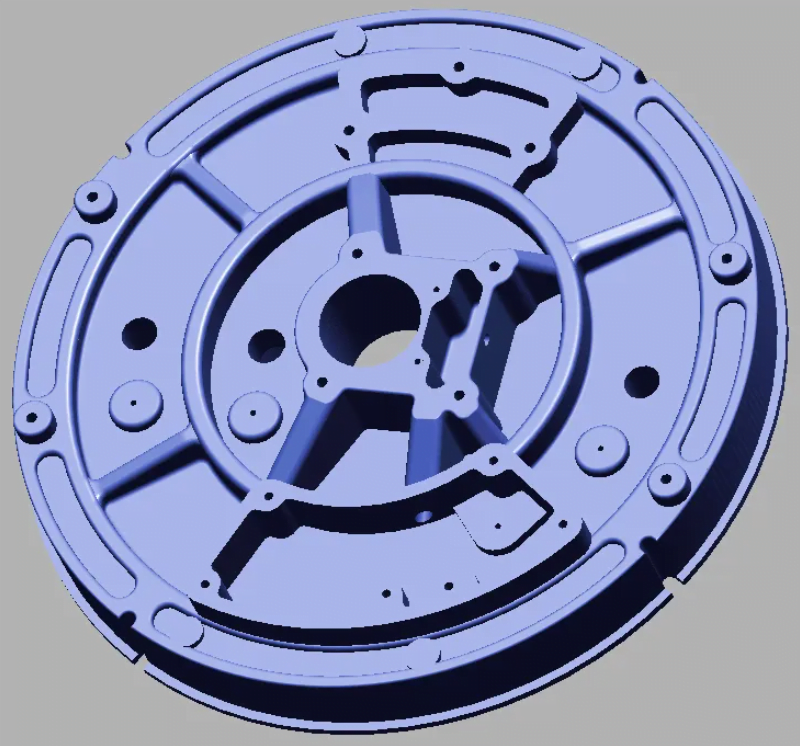

Plastic & Composites Part 3D Design

Product Design + Mass Production

From design to finished product, one-stop processing, full control

Products are the core lifeblood of an enterprise. The importance of product design to an enterprise is self-evident. How to do a good job in product design is an issue that every enterprise needs to attach great importance to.However, most small and medium-sized enterprises do not have the strength to independently complete the design and development of new products, and most of them need to seek the cooperation of product design companies, such as professional wsmcmold companies.

We provide you with professional product design solutions

Wsmcmold focuses on the design of plastic injection daily necessities, composite molded products, military products, auto parts products, home appliances, medical products and other fields. Supply chain integration services (mold design and production, small batch trial production, production supply control) and other service modules. Here you can enjoy the precise service process, our most cost-effective design, can help you save 35% of the cost.

We believe in the power of design, and believe that excellent design can not only create commercial value, but also create huge social value.

Structural Design Principles for Plastic Injection Molded and Composite Molded Part Development

1. The structural design should be reasonable: the assembly clearance should be reasonable, and all plug-in structures should reserve clearance; ensure sufficient strength and stiffness (safety test), and properly design a reasonable safety factor.

2. The structural design of plastic parts should comprehensively consider the manufacturability of the mold, and try to simplify the manufacturing of the mold.

3. The structure of plastic parts should consider its plasticity, that is, the injection molding production efficiency of parts should be high, and the scrap rate of injection molding should be reduced as much as possible.

4. Consider the ease of assembly production (especially not conflicting with assembly).

5. The structure of plastic parts should adopt a standard and mature structure as much as possible, the so-called modular design.

6. For universal/common use, try to use existing parts and do not open new molds.

7. Take into account the cost.

wsmcmold has its own complete product design process, which is also an effective guarantee for the project to be completed on time and with quality. Based on our many years of design experience, we will share the product design process and specifications, and the approximate process steps of product design development, so that everyone can have a better understanding of product design.

First of all, before starting the product design work, wsmcmold will have a deep understanding of the customer’s needs, including which functions the customer wants to achieve, the customer’s budget, the positioning of the product, the post-promotion model, and the strengths and weaknesses of market competitors.

Secondly, after understanding the needs of customers, it is necessary to conduct market research and dig deep into the pain points of consumers to ensure that the designed products are what consumers need. An excellent product comes out to meet the needs of customers, but also to meet the needs of consumers, to know ourselves and our enemies, we can win every battle!

Furthermore, through the above investigation, at this time, wsmcmold should have a certain understanding and idea of the product, how to realize the idea? That is to design the appearance and internal structure function of the product through the mode of hand-drawn sketches. This also includes the color of the product, the shape of the product, the functions it carries, the parts used, and so on.

Also, look for deficiencies and inconsistencies in your products and improve them. This is the most critical step that determines whether the product is truly completed.