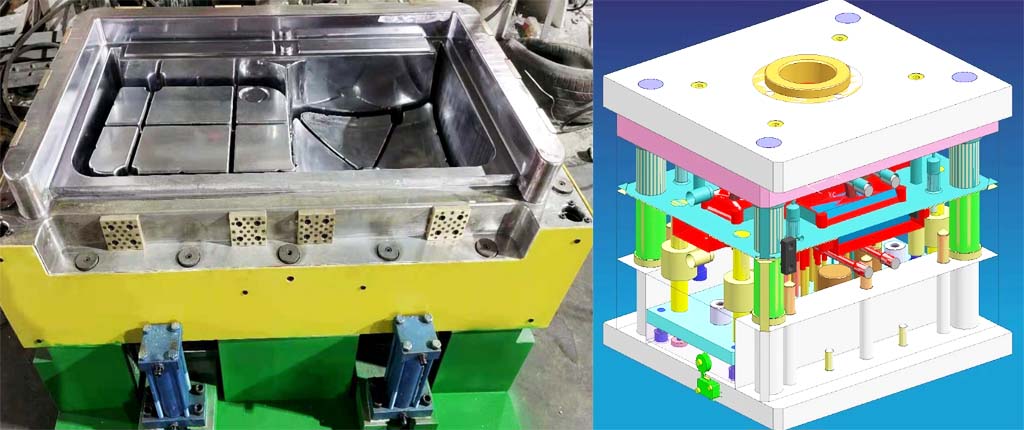

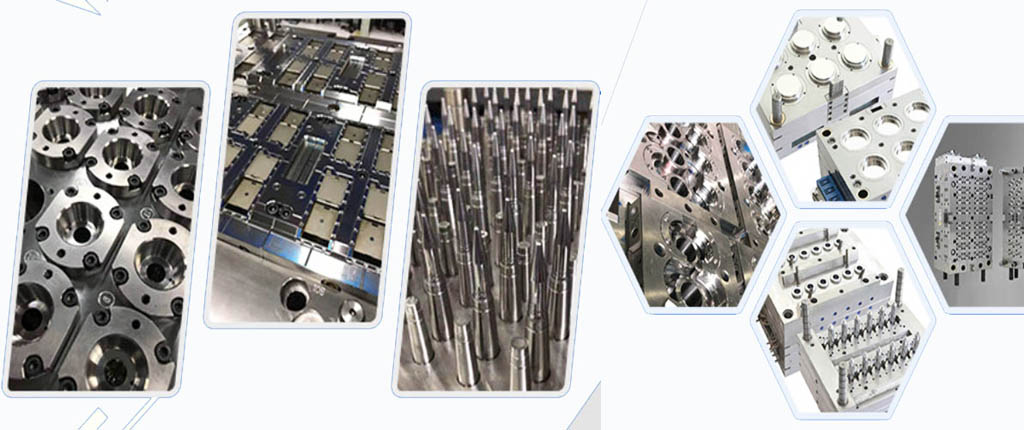

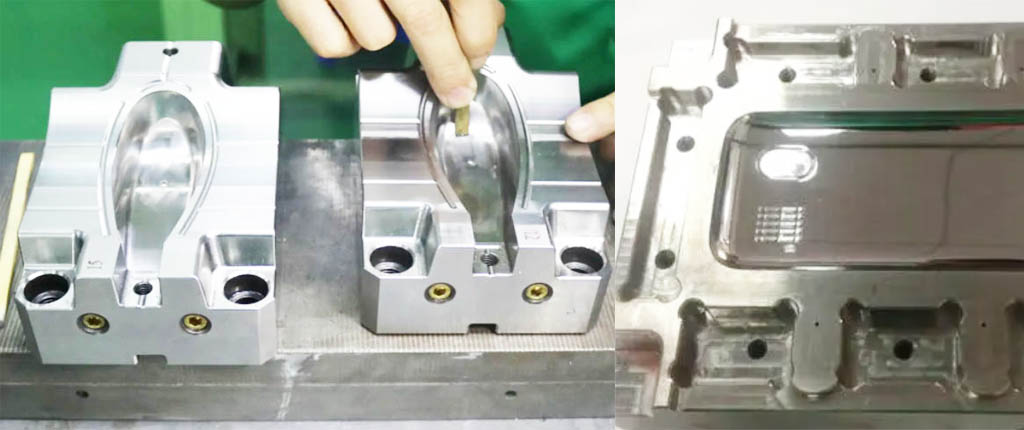

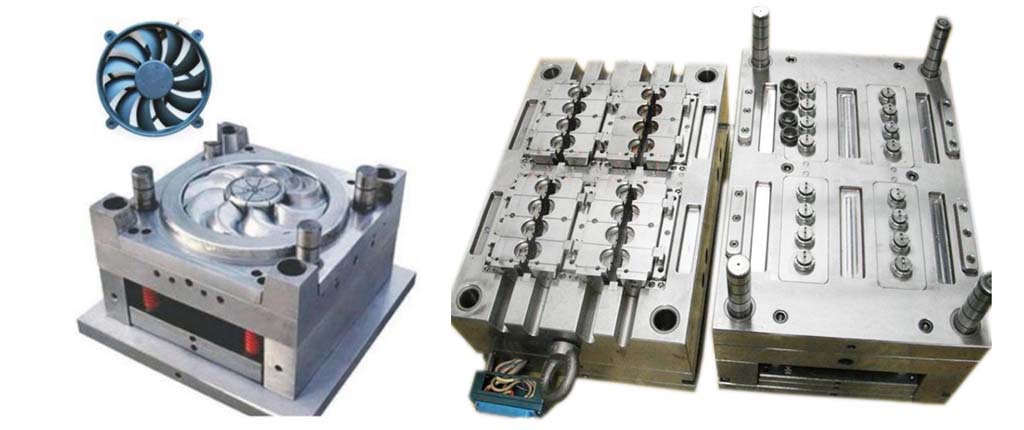

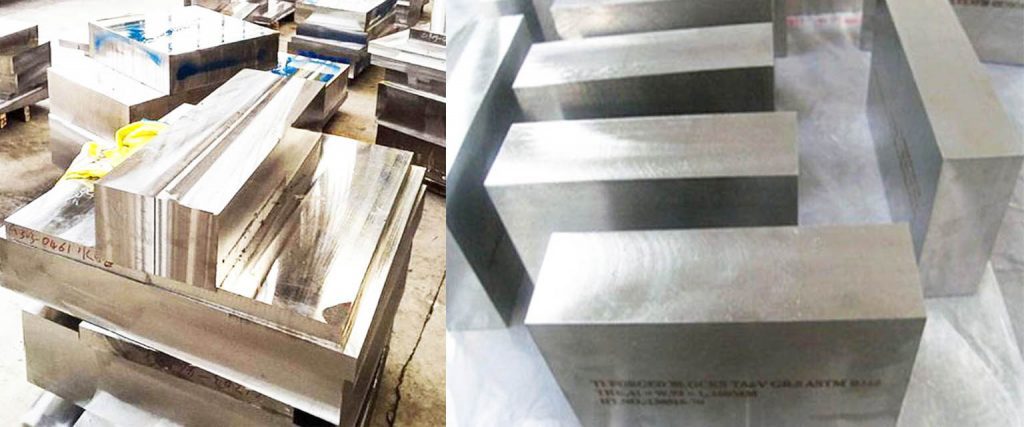

Plastic injection molds are tools that are designed to shape molten plastic material or resin. This is done by injecting the material into a mold cavity, which is then cooled and solidified to create a finished product. These molds can be made from various materials such as steel, aluminum, or copper.

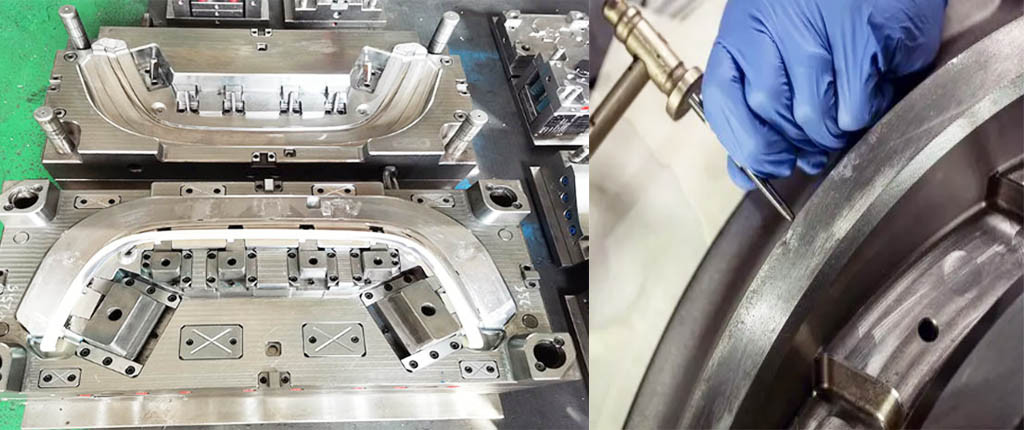

Composite compression molding molds are also tools used to create composite materials such as fiber-reinforced plastics. This process involves placing the fibers into the mold cavity, and then injecting a resin or binder to hold the fibers in place. The mold is then compressed, allowing the material to set and take on the desired shape.

Both plastic injection molds and composite compression molding molds are used in the manufacturing industry to make a wide range of products. These molds are typically designed and created by skilled engineers and mold makers, and can be customized to meet specific product needs.