Fiberglass(FRP/SMC) Car Bumper Mold

Innovation Professional Efficiency Win-Win

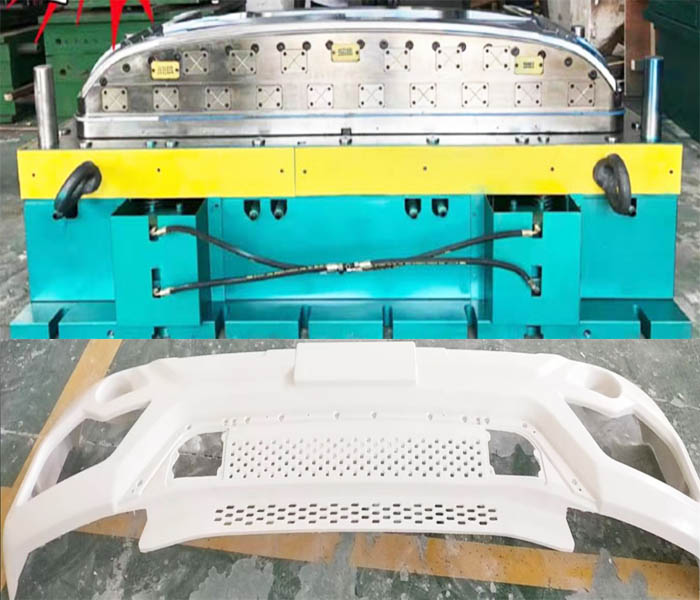

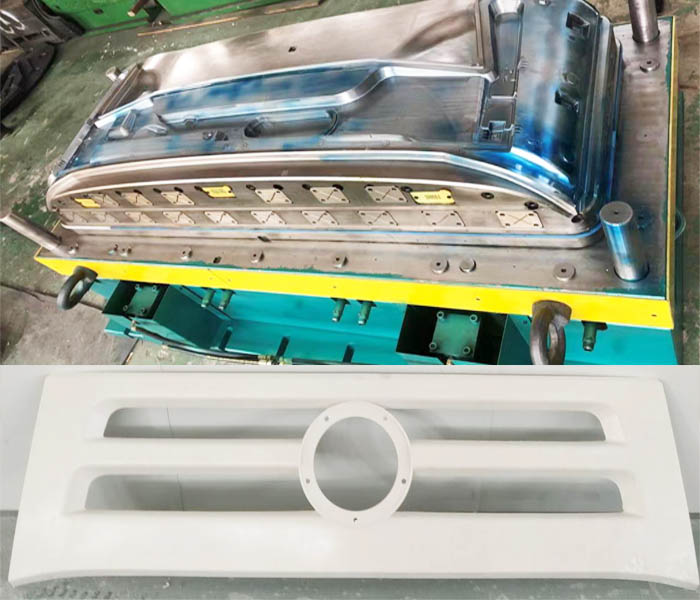

Various types and specifications of bumper moulds

Fiberglass(FRP/SMC) Car Bumper Mold Maker

Fiberglass car bumper mold manufacturers in China, also known as glass fiber reinforced plastic automotive bumper molds. Fiberglass material are widly used to make the front and rear bumpers of cars, trucks, and other vehicles. FRP is a lightweight, high-strength, and corrosion-resistant material commonly used in automobile manufacturing,which is compression molding.

Fiberglass FRP Bumper Mold

Fiberglass FRP bumper mold manufacturers play a key role in the automotive manufacturing industry, providing automakers with high-quality molds to produce safe, durable and aesthetically pleasing automotive bumpers. Their work is critical to the growth and innovation of the automotive industry

SMC Car Bumper Mold

SMC car bumper molds offer a combination of high strength, light weight, the ability to create complex shapes, and corrosion resistance, making them ideal for use in automotive manufacturing and other industries.These features contribute to the production of high-performance automotive bumpers

Composite Car Bumper Mold

Composite car bumper molds are used to make bumpers for automobiles and other vehicles. The materials used are composite materials, usually including glass fiber reinforced plastic (FRP) or carbon fiber reinforced plastic (CFRP), which are formed by compression molding by Hydraulic Press

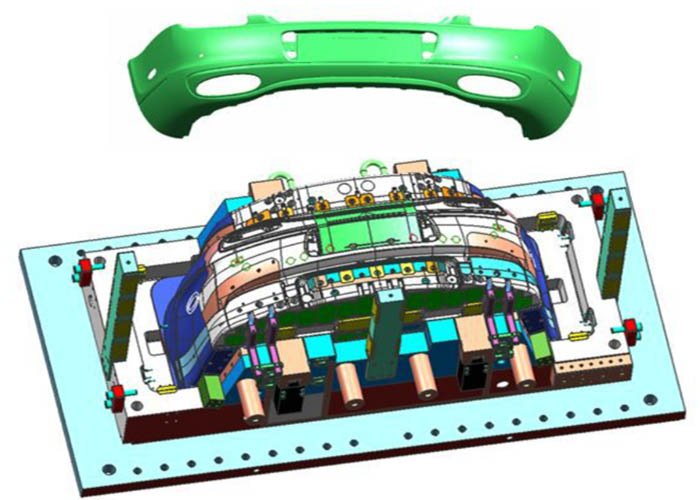

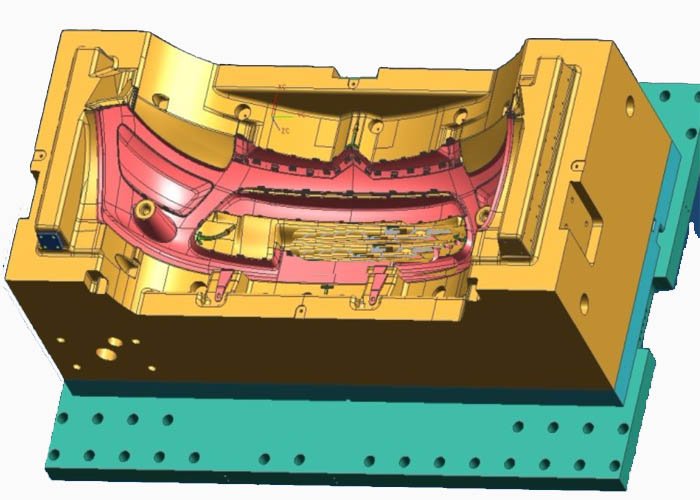

Plastic Injection Auto Car Bumper Mold

There are many plastic bumpers on the market, which are produced by injection molding bumper molds. Plastic injection car bumper molds also play a key role in the automotive manufacturing industry, they are a key tool for making high-quality automotive bumpers with good appearance and performance. These molds require a high degree of precision manufacturing and maintenance to ensure their performance and longevity.

High-quality auto bumper mould can increase injection speed and product consistency, productivity is critical to automotive manufacturing,thereby reducing production costs.

We adhere to the business purpose of “customer first, excellence, quality win”, welcome to inquire bumper molds.

WS MOLD is an expert in the industry when it comes to making fiberglass compression molding (SMC/BMC) bumper molds. Our molds are designed and manufactured with high precision to meet customers’ customized needs and high standards.

SMC FRP Car Bumper Mold compression Mold

Plastic Injection Auto Car Bumper Mould

Contact Us Now For Your Plastic Injection Car Bumper Mold and Composite Fiberglass SMC Compression Car Auto Bumper Mold Solution

Our Plastic Injection Molding and Fiberglass Compression Molding Bumper Molds feature high quality, precision and reliability. Whether it is in automobile manufacturing or other fields, we meet the needs of customers with professional mold making services and provide excellent solutions for their production.

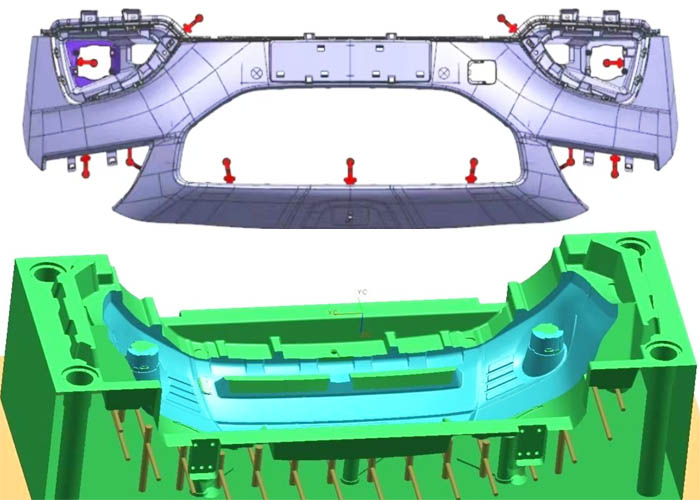

Automobile Car Bumper Mold Design

Automobile Bumper Mold

Car Bumper Mould

Automotive Bumper Mould

Why Choose Fiberglass FRP Car Bumper Mold

More and more people choose fiberglass(FRP) bumper moulds to produce fiberglass material bumpers, this is because FRP bumpers have some unique advantages that make them very valuable in automobile manufacturing and other fields, the following are FRP bumper molds The main features of :

Lightweight: FRP material is relatively lightweight, so the bumper made of FRP bumper mold has a lower weight. This helps improve the vehicle’s fuel efficiency and performance.

HIGH STRENGTH: Despite being lightweight, FRP bumpers have exceptional strength and stiffness, providing excellent crash protection and structural support.

Corrosion Resistance: FRP material has good resistance to corrosion, so it is not easy to rust or be damaged by environmental factors.

Complex shape fabrication: Fiberglass bumper molds can fabricate complex shapes and designs, including curves, bumps, and various design elements. This allows automakers to achieve more innovation and design freedom.

High temperature and chemical resistance: FRP materials generally have excellent high temperature and chemical resistance, allowing them to perform well in a variety of different environmental conditions.

Production efficiency: FRP bumper molds can usually achieve high production efficiency, which helps to reduce production costs.

Recyclability: FRP materials can be recycled, which helps to reduce waste and environmental impact, and meets the requirements of sustainable development.

Customer customization: Mold manufacturers usually customize FRP bumper molds according to customer needs and specifications, including customization in shape, size and design requirements.

Due to the above series of features of FRP bumper, this makes FRP bumper mold very popular.

Our company specializes in the production of FRP automobile bumper molds, with exquisite workmanship, reliable quality, reasonable price and exquisite workmanship, by introducing advanced CAE/CAD/CAM software and importing facilities, the company project manager is responsible for the whole process from order confirmation to delivery, and even after-sales service.

The company’s bumper mold design team has many years of experience in communicating with European and American customers, and always listens to customer needs.We are able to manufacture bumper molds of any kind and specification according to your requirements.

Sincerely welcome friends from home and abroad to visit us to talk about bumper mold. We will work with you with the best price and best delivery, so that our most valuable customers can seize market opportunities as soon as possible.