SMC Meter Box Mold

Revolutionize Your Meter Box Design with SMC Compression Meter Box Mold Magic! Unleash Style, Precision and Durability – Elevate Your Electric Meter Box to New Heights

Welcome to our world specializing in SMC Meter Box Mold (Sheet Molding Compound Electric Meter Box Mold)! As an indispensable part of the power system, the performance and quality of the meter box directly affect the stability and reliability of the power supply. In order to meet complex requirements such as high performance, weather resistance and corrosion resistance, we specialize in designing and manufacturing high quality compression SMC Meter Box molds.

SMC Meter Box Mold

BMC Meter Box Mold

Fiberglass Electric Meter Box Mold

What is SMC Meter Box Mold?

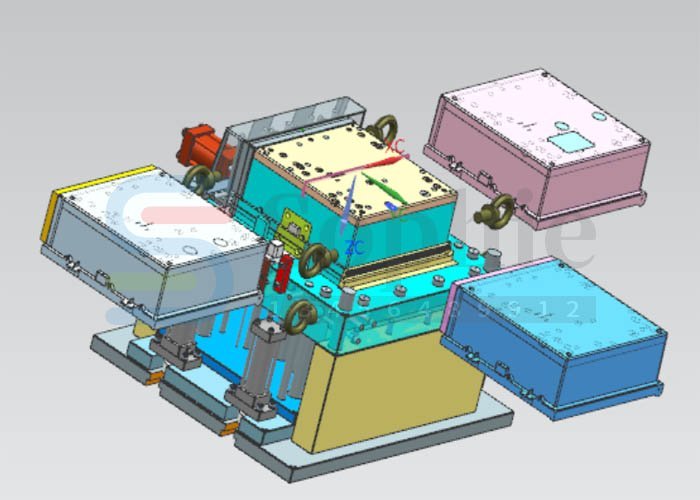

SMC Meter Box Mold is a mold specially designed for meter box manufacturing, using advanced Sheet Molding Compound (SMC) material,it is compression molding meter box mold. As a composite material, SMC mainly consists of high-strength glass fibers, strong resins and some effective fillers. Through precise mixing and processing, it creates end products with excellent mechanical properties and excellent durability.

During the mold design phase, we pay attention to every detail and strive to achieve a balance of excellent performance and high durability. This involves an in-depth understanding of the shape, size, structural requirements, and other special performance criteria of the meter box. Our mold design not only takes into account the beautiful appearance, but also focuses on ensuring that the meter box has key properties such as high strength, corrosion resistance and good insulation.

In the actual manufacturing process, we ensure the exquisite manufacturing of SMC Meter Box Mold through advanced processes. From the mixing of SMC materials, to filling in the mold, to high-pressure compression, solidification and final cooling and demoulding stages, every step is strictly controlled. This ensures high precision and consistency of the molded meter box casing.

We focus on achieving the best balance of performance and cost-effectiveness. Through sophisticated mold design and optimization of manufacturing processes, we aim to provide high-strength, corrosion-resistant, and well-insulated meter box casings while maximizing manufacturing efficiency and controlling production costs. This makes our SMC Meter Box Mold ideal for meeting high standards and demands.

In our philosophy, it is not just about manufacturing molds, but also about providing customers with reliable solutions. By focusing on quality, performance and innovation, our SMC Meter Box Mold will help you produce excellent meter box products and provide stable and reliable support for the power system.

SMC Meter Box Mold manufacturing Process Flow

The manufacturing process of SMC Meter Box Mold involves multiple steps, including material preparation, mold design and manufacturing, molding and curing. The following is the general SMC Meter Box Mold manufacturing process flow

Material preparation

- SMC material formula design: Determine the appropriate SMC material formula, including the proportions of glass fiber, resin, filler and additives, to meet the performance requirements of the meter box mold.

- Raw material preparation: Prepare various raw materials for SMC materials according to the formula to ensure that their quality meets the requirements.

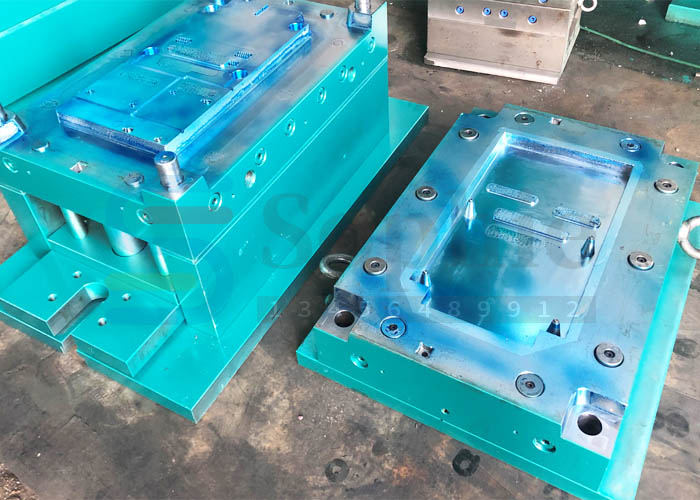

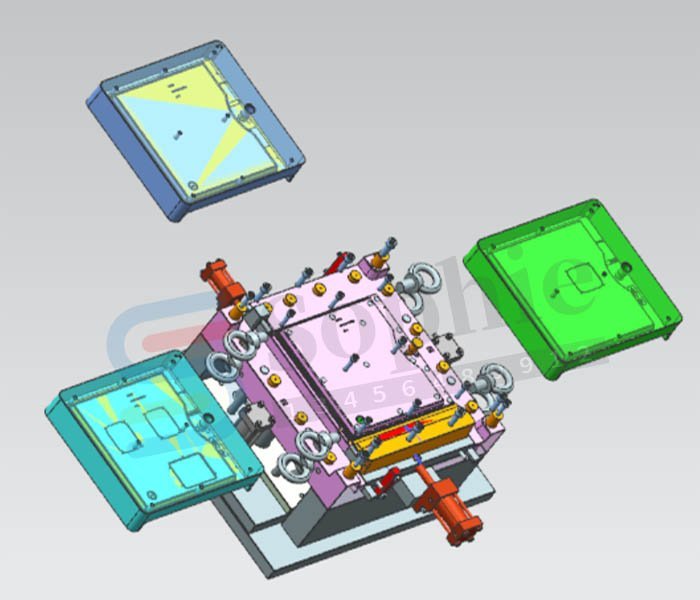

Mold design and manufacturing

- Meter box design: Design the model according to customer requirements and specifications of the meter box, including shape, size, wall thickness, etc.

- Mold design: Based on the design of the meter box, the SMC Meter Box Mold is designed, taking into account factors such as material flow, temperature and pressure during filling, compression and solidification.

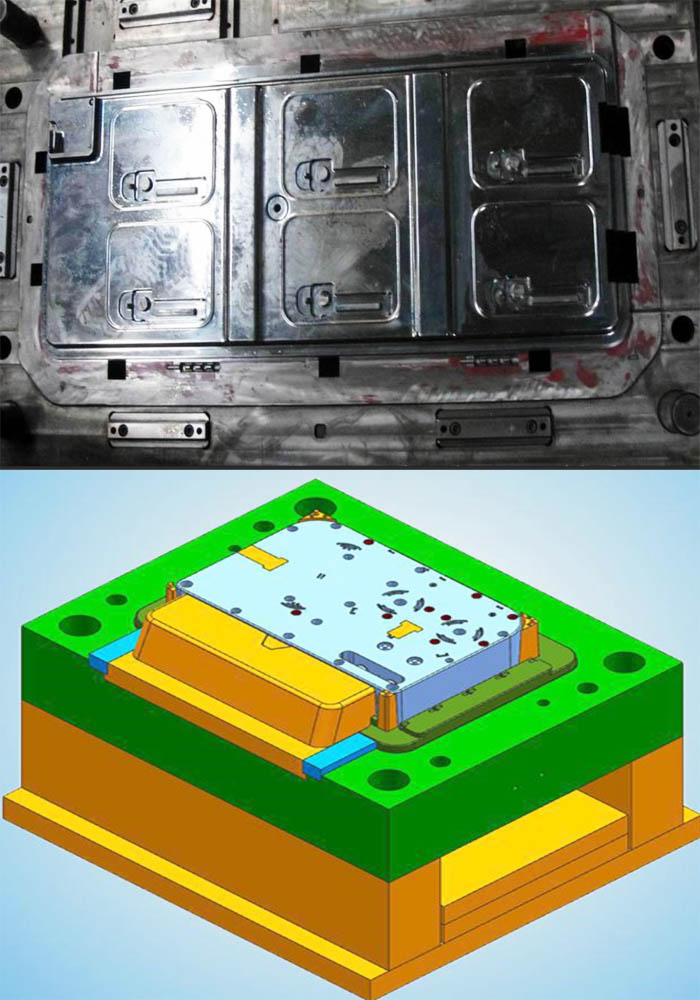

- Mold manufacturing: Use high-strength, heat-resistant materials to manufacture the SMC Meter Box mold to ensure it has sufficient durability and stability.

Material mixing and filling

- Material mixing: Mix the pre-prepared SMC materials to ensure that the ingredients are evenly distributed.

- Filling the mold: Fill the mixed SMC material into the pre-designed SMC Meter Box mold.

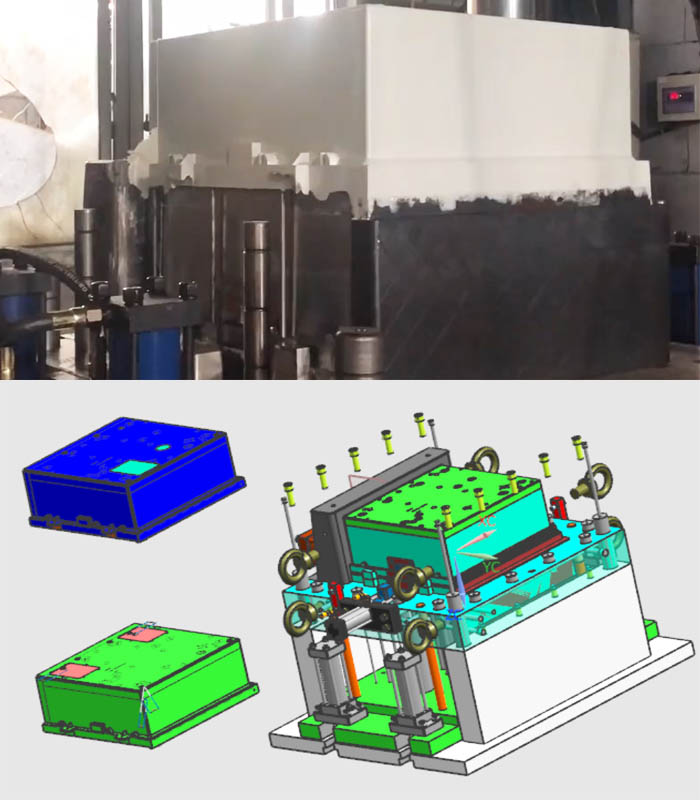

Compression and solidification

- Apply pressure: Use pressure equipment to apply high pressure to compress the SMC material into the desired shape in the mold.

- Curing process: Under certain temperature conditions, the SMC material is cured to ensure that it has the required hardness and strength.

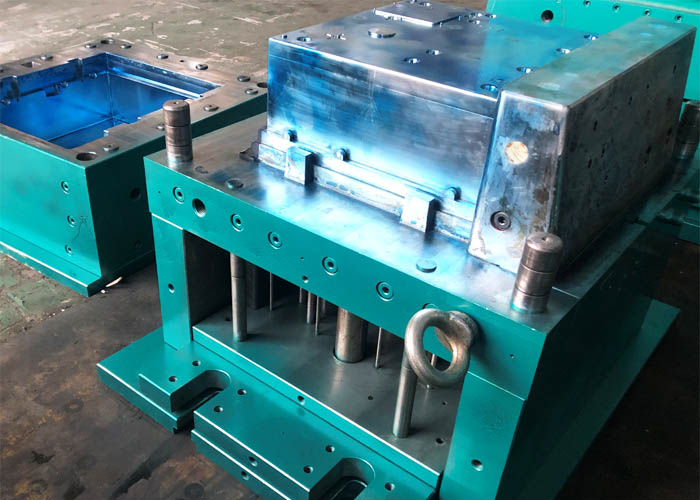

Cooling and demoulding

- Cooling: Cool the mold to ensure that the material in the formed SMC Meter Box mold can maintain the required shape and properties.

- Demoulding: Take out the cured SMC Meter Box from the mold, and be careful to prevent damage to the finished product.

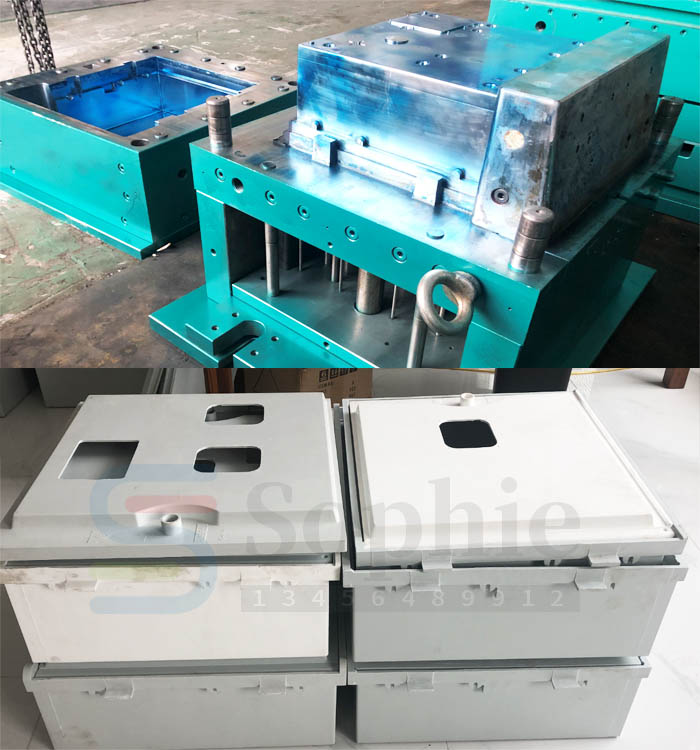

Post-processing and finishing

- Trimming: Trim the finished product after demoulding to ensure that the edges are smooth.

- Surface treatment: Surface treatment can be carried out as needed, such as grinding, spraying, etc., to improve the appearance quality.

Quality inspection

- Appearance inspection: Check the appearance of the finished product to ensure there are no cracks, bubbles and other defects.

- Dimensional inspection: Measure the dimensions of the finished product to ensure it meets the design requirements.

- Performance test: Carry out necessary performance tests, such as mechanical strength, insulation, etc.

Packaging and delivery

- Packaging: Properly package the finished product to prevent damage during transportation.

- Delivery: Deliver the final SMC Meter Box Mold product to the customer.

The entire process requires precise control and quality management to ensure that the final product meets design standards and customer requirements.

Why choose our SMC Meter Box Mold?

We not only provide excellent products, but also focus on customer satisfaction. By partnering with us, you will receive high performance, reliable and affordable SMC Meter Box Mold, providing a trustworthy solution for your power system.

High-precision design: Our SMC Meter Box molds are precision-engineered to ensure that the shape and size of the meter box accurately meet specifications.

High-quality material selection: The use of high-quality SMC materials ensures that the meter box mold has excellent mechanical strength, weather resistance and corrosion resistance.

Exquisite workmanship: We have advanced manufacturing processes and technologies, and every step from material mixing to mold forming is strictly controlled to ensure the consistency and quality of the final product.

Customized design: Based on different customer needs, we provide flexible customized design options to meet the requirements of various meter box shapes and specifications.

Sustainability: We are committed to environmental protection and sustainable development, selecting recyclable materials and energy-efficient processes to reduce environmental impact.

If you are interested in our SMC Meter Box Mold or have any customization needs, please feel free to contact us. Our professional team will wholeheartedly provide you with technical support and consulting services. Choose us, choose high quality and reliability guaranteed.

The importance of SMC meter box mold

SMC (Sheet Molding Compound) meter box mold plays a key role in the manufacturing of meter boxes. Its quality and design directly affect the performance, appearance and production efficiency of the final product. The following is the importance of SMC meter box mold:

Material filling and fluidity

The design of the SMC meter box mold determines the filling and fluidity of the SMC material in the mold. Excellent mold design ensures that the material fills the mold evenly, avoiding air bubbles, even distribution and poor flow, thus ensuring the quality of the final meter box.

Precise size and appearance

The high-precision design of SMC meter box molds ensures that the final product meets the design specifications and has consistent size and appearance. This is crucial to meeting customer requirements and improving market competitiveness.

Improved production efficiency

Excellent mold design can improve production efficiency and reduce production costs. By reducing scrap rates, increasing production speed, and reducing equipment downtime, SMC meter box molds can bring higher production efficiency.

High temperature and high pressure resistance

SMC meter box molds need to be able to withstand high temperature and high pressure environments to ensure that the SMC material can maintain the required shape and performance during the curing process. High-quality mold materials and manufacturing processes are key to ensuring this resistance.

Mold surface quality

The quality of the mold surface directly affects the appearance of the SMC meter box. Smooth, clear, and flawless mold surfaces can create a high-quality meter box appearance and enhance the product’s market image.

Diversity and customization capabilities

SMC meter boxes may need to cope with the production needs of different specifications and models, so mold design needs to have flexibility and customization capabilities to meet the special needs of different markets and customers.

Cost-effectiveness

Well-designed SMC meter box molds not only improve production efficiency, but also help reduce production costs. Greater cost efficiencies can be achieved by reducing scrap rates, increasing production speeds and extending mold life.

Market Applications of SMC Meter Box Mold

SMC Meter Box Mold is mainly used in the manufacturing process of electric meter boxes in the market. The following are its main application areas in the market:

Electric power industry: SMC Meter Box Mold is mainly used in the electric power industry to manufacture meter boxes installed outside buildings. These meter boxes are used to measure and record electrical energy usage and are the basis for electricity supply and billing.

Construction and Residential Projects: In construction and residential projects, a large number of meter boxes are required to provide independent metering of electricity to each user. SMC Meter Box Mold is used to produce these meter boxes to meet the electrical needs of buildings and residential buildings.

Industrial field: Industrial sites usually also need electric meter boxes to monitor and measure electric energy usage to ensure the normal operation of production equipment. SMC Meter Box Mold plays a key role in manufacturing these industrial meter boxes.

Renewable energy projects: With the promotion of renewable energy, such as solar and wind energy projects, meter boxes are needed to monitor and meter the generation and use of renewable energy. SMC Meter Box Mold also plays an important role in these projects.

Smart Grid: With the development of smart grid, meter boxes need to adapt to new smart meters and communication technologies. SMC Meter Box Mold can be designed and manufactured according to the requirements of these new technologies to support smart grid requirements.

Overall, the application scope of SMC Meter Box Mold in the market mainly covers multiple fields related to meter box manufacturing and power supply. With the development of power systems and the continuous advancement of technology, the demand for high-performance, durable and customized meter boxes will continue to grow, driving the application of SMC Meter Box Mold in the market.

Market Trends of SMC Meter Box Mold

SMC Meter Box Mold is affected by multiple trends in the market, which reflect the development direction of the industry and the needs of the market. The following are some trends that SMC Meter Box Mold may face in the market:

Intelligent and digital needs

As the power system changes to intelligence, the design and manufacturing of meter boxes may need to adapt to the installation of new smart meters and monitoring systems. SMC Meter Box Mold will face higher requirements to support the digital and intelligent functions of the meter box.

Green and Sustainable Development

As concerns about environmental protection and sustainable development rise, the demand for SMC Meter Box Mold manufactured using environmentally friendly materials and processes is likely to increase. Manufacturers may increasingly focus on using renewable materials and reducing the environmental impact of their production processes.

Increased demand for customization

The industry has an increasing demand for customized products to adapt to the special requirements of different regions and projects. This will require SMC Meter Box Mold to be flexible and customizable to meet the special needs of different markets and customers.

The importance of weather resistance and corrosion resistance

Meter boxes installed outdoors need to have good weather resistance and corrosion resistance to cope with various climate conditions. Therefore, the demand for the performance of SMC Meter Box Mold products in this area is likely to increase.

Emerging market demand

In emerging markets, such as Asia, Africa, and Latin America, the development of power infrastructure is likely to drive growing demand for meter boxes, thereby affecting the market for SMC Meter Box Mold.

Technological innovation and material improvement

With the continuous innovation of technology, the requirements for the performance of SMC materials used in meter box molds are also constantly increasing. Manufacturers may seek more advanced materials and manufacturing processes to improve SMC Meter Box performance and reliability.

Overall, the market trend of SMC Meter Box Mold will be affected by multiple factors such as the development of the power industry, increased environmental awareness, and technological innovation. Manufacturers need to pay close attention to these trends and constantly adapt products and production processes to adapt to changes in the market and meet evolving customer needs.