Table of Contents

ToggleIntroduction compression molding helmet mold

Compression molding helmet molds is becoming more and more popular, becuase the demand for high-performance helmets in sports, military, and industrial safety applications is growing rapidly. To meet this demand, manufacturers are turning to advanced manufacturing techniques like compression molding to produce durable, lightweight, and cost-effective helmet molds. Armenia, with its emerging manufacturing sector, is becoming an attractive destination for composites compression helmet mold production.

In this blog, we’ll explore:

- The benefits of compression molding for helmet molds

- Why Armenia is a strategic location for helmet mold production

- The role of composite materials in enhancing helmet performance

- Future trends in helmet manufacturing

Why Compression Molding for Helmet Molds?

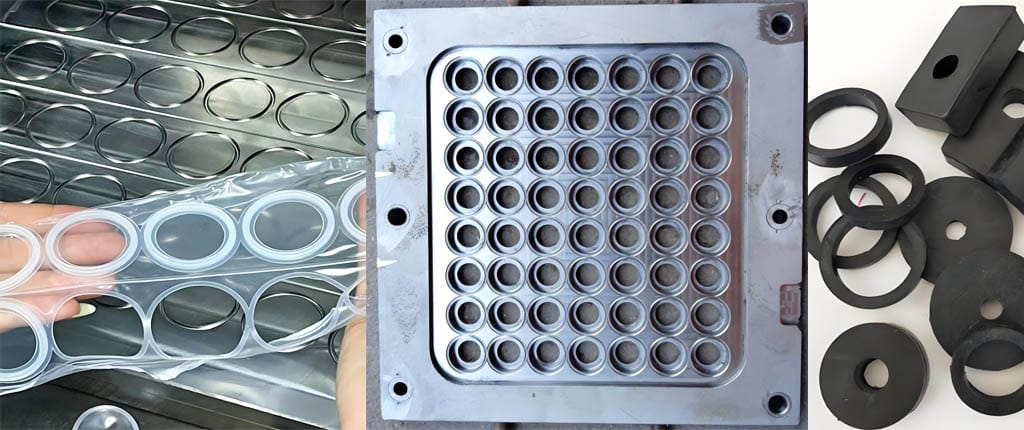

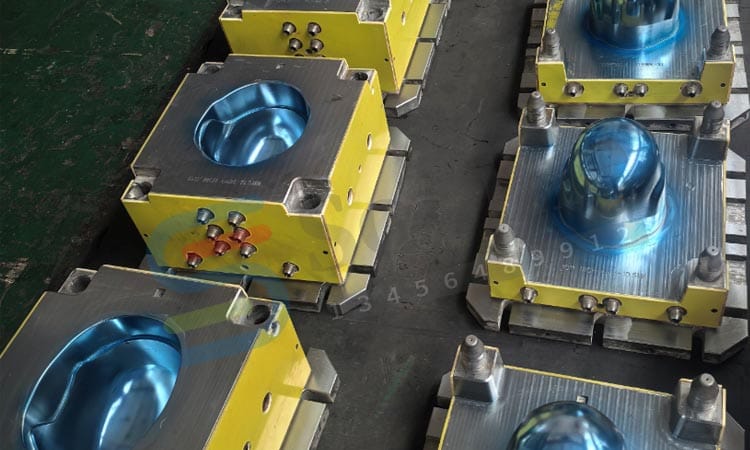

Compression molding is a manufacturing process where a preheated composite material is placed into a mold cavity and compressed under high pressure and temperature until it cures into the desired shape. This method is ideal for producing high-precision helmet molds due to several advantages:

1. High Strength & Lightweight Properties

Helmets made through compression molding using carbon fiber, fiberglass, or Kevlar composites offer superior strength-to-weight ratios compared to traditional materials like steel or plastic. This ensures better protection without compromising comfort.

2. Cost-Effective for Mass Production

Once the mold is designed, compression molding allows for high-volume production with consistent quality, reducing per-unit costs—a critical factor for manufacturers supplying global markets.

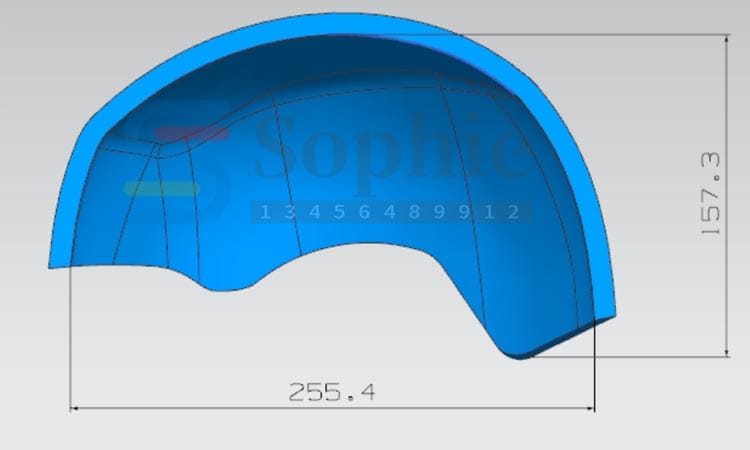

3. Complex Geometries & Customization

Compression molding enables intricate designs, including multi-density liners and impact-absorbing structures, which are essential for helmets used in sports (e.g., cycling, football) and military applications

4. Durability & Impact Resistance

Composite materials used in compression molding provide excellent energy absorption, crucial for helmets designed to protect against high-impact collisions.

Why Armenia for Helmet Mold Production?

Armenia is emerging as a competitive hub for advanced manufacturing, including composite helmet mold production. Here’s why:

1. Skilled Workforce & Engineering Expertise

Armenia has a strong tradition in engineering and material sciences, with universities and technical institutes producing skilled professionals in composite manufacturing and mold design.

2. Strategic Location & Trade Advantages

Situated between Europe and Asia, Armenia offers cost-effective production with access to key markets. Free trade agreements with the Eurasian Economic Union (EAEU) and other regions make exporting helmet molds easier.

3. Growing Composites Industry

Local companies are investing in advanced composite materials and molding technologies, making Armenia an ideal partner for helmet manufacturers looking for high-quality molds.

4. Government Incentives for Manufacturing

Armenia’s government supports industrial growth through tax benefits and grants for manufacturers, encouraging foreign investment in compression molding and composite production.

The Role of Composite Materials in Helmet Molds

Modern helmets rely on composite materials to achieve optimal performance. Key materials used in compression-molded helmet molds include:

- Carbon Fiber: Extremely strong and lightweight, ideal for high-performance helmets.

- Fiberglass: Cost-effective while maintaining good impact resistance.

- Kevlar & UHMWPE (Ultra-High-Molecular-Weight Polyethylene): Used in military and ballistic helmets for superior protection.

- Thermoset Resins (Epoxy, Polyester): Provide excellent curing properties in compression molding.

These materials allow for multi-layered helmet designs, combining rigid outer shells with energy-absorbing inner liners for maximum safety.

Future Trends in Helmet Mold Manufacturing

As technology evolves, helmet production is set to improve further:

1. Smart Helmets with Embedded Sensors

Future helmets may integrate impact sensors, communication systems, and augmented reality (AR) displays, requiring advanced mold designs.

2. Sustainable Composites

Eco-friendly materials like flax fiber composites and bio-resins are gaining traction, aligning with global sustainability goals.

3. Automation & AI in Compression Molding

Automated presses and AI-driven quality control will enhance precision and reduce defects in helmet mold production.

Conclusion

The combination of compression molding technology, composite materials, and Armenia’s manufacturing potential makes it an exciting time for helmet production. Whether for sports, military, or industrial use, high-quality helmet molds produced through compression molding offer unmatched safety, durability, and cost efficiency.

For manufacturers looking to source or produce composite compression helmet molds, Armenia presents a compelling opportunity with its skilled workforce, strategic location, and growing composites industry.

Are you interested in compression-molded helmet molds for your business? Partner with experts in Armenia to leverage cutting-edge manufacturing solutions!