Compression molding SMC integral bathroom mold,SMC (Sheet Molding Compound) is an engineering plastic material widely used in the manufacture of composite materials of complex shapes. SMC overall bathroom mold is a tool used to manufacture overall bathroom products, such as bathtubs, showers, toilets, etc.

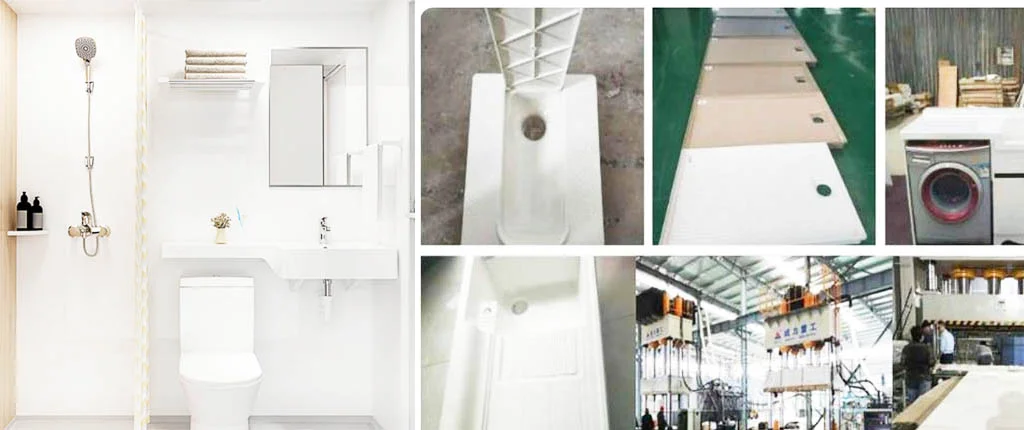

SMC overall bathroom is generally compression molded with SMC composite materials. SMC overall bathroom molding molds include bathtubs, bath racks, sinks, toilets, chassis, wall panels and other molds. Among them, SMC chassis and wall panels need to be molded at one time. Only hydraulic presses over 2500 tons can be produced. Molded SMC overall bathroom products, high density, high strength, smooth surface, excellent electrical insulation properties, mechanical properties, thermal stability, chemical corrosion resistance.

Table of Contents

ToggleCompression molding SMC integral bathroom mold feature

1. Material

SMC overall bathroom molds are usually composed of high-strength glass fiber reinforced thermosetting resins. This material has excellent mechanical properties, corrosion resistance and weather resistance, and is suitable for the manufacture of bathroom products.

2. Manufacturing process

Manufacturing SMC bathroom molds usually requires compression molding. During this process, the SMC material is heated and pressurized so that it flows sufficiently and fills the shape of the mold. The material in the mold is then cured at high temperatures to form the shape and structure of the bathroom product.

3. Production efficiency

The use of SMC integral bathroom molds can achieve mass production, improve production efficiency, reduce production costs, and ensure product consistency and quality.

SMC fiberglass bathroom floor mold tray (chassis) mould for the whole bathroom

1. SMC material (widely used in aircraft cabins, motor car inner walls), light material, high density, high strength, anti-aging, green environmental protection.

2. The chassis mold adopts a hydraulic press of more than 2000 tons, and the molding temperature is 156 degrees. The chassis and the water retaining flanging are molded at one time without any cutting and splicing, and there is no leakage like an “ashtray”.

3. Comes with 12%. The slope of the water, the “bottom of the pot” design, the floor drain is a low point, and the chassis can be flattened without leakage.

4. The thickness of the chassis is 3.5mm, and the thickness of the reinforcing ribs is 75mm, which strengthens the strength of the chassis and ensures that the chassis does not deform.

5. The overall bathroom mold can be customized according to customer requirements.

Measures to eliminate the "orange peel" of the workpiece

When it is found that the surface quality is not good, many people increase the polishing pressure and prolong the polishing time, which tends to make the surface quality worse.

The following methods can be used to remedy the above problems:

(1) Remove the defective surface, grind the particle size a little coarser than the previous one, and then grind it, and the polishing force is lower than the previous one.

(2) Stress relief is carried out at a temperature 25°C lower than the tempering temperature. Before polishing, use the finest grit size for grinding until a satisfactory effect is achieved, and finally polish with a lighter force.

The basic process of the SMC integral bathroom compression molding process is to put a certain amount of pretreated molding material into the preheated mold, and apply high pressure to fill the mold cavity with the molding material. Under a predetermined temperature condition, the molding compound is gradually solidified in the mold cavity, and then the SMC product is taken out from the mold, and then necessary auxiliary processing is performed to obtain the final product.

SMC bathroom molds are mainly used in the compression molding of shower room waterproof trays, washbasins, bathtubs, integral bathrooms and other products. The products have the characteristics of good surface finish, high strength, heat resistance and stability, and pollution resistance. Our company has rich mold production experience. , and provide customers with OEM services.