What is compression plastic moulding

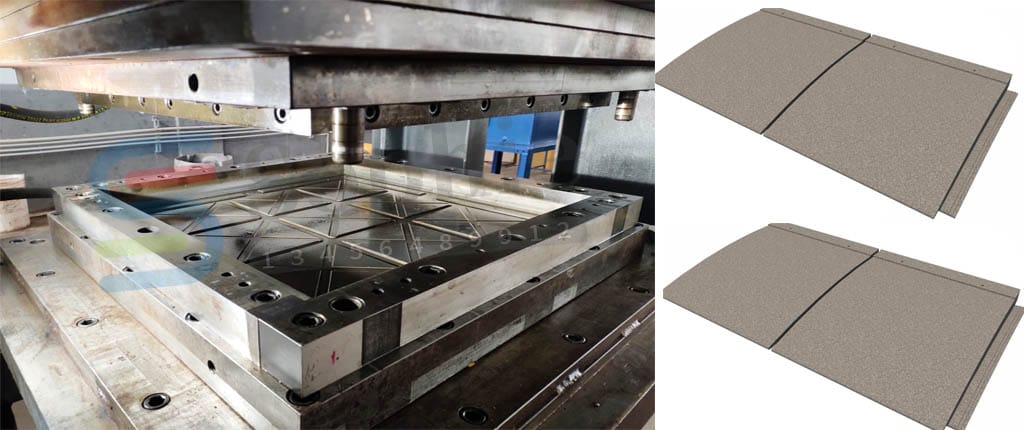

Compression plastic moulding is a method of molding plastic materials by pressure in a heated mold, usually used to produce thermosetting plastics and reinforced plastic products. This method is particularly suitable for producing plastic products with complex structures, precise dimensions or fine patterns.

Compression molding of plastics is a process that thrives under high-volume, high-pressure conditions, making it ideal for creating complex components with strong fiberglass reinforcements. This technique is particularly effective for producing large-scale parts with intricate details. It is also an economical choice due to its efficiency in material usage, resulting in minimal waste.

Table of Contents

ToggleWorking principle of plastic compression mold

The working principle of plastic compression mold includes the following steps:

- Raw material preparation: Select suitable plastic raw materials and perform pretreatment, such as drying, crushing, etc.

- Mold design: Design and manufacture corresponding molds according to the shape and size requirements of the product.

- Molding: Put the pretreated raw materials into the mold and perform compression molding under high temperature and high pressure conditions.

- Subsequent processing: Perform subsequent processing on the molded products, such as polishing, painting, etc., to meet the use requirements

In the compression molding process, the mold is usually composed of two or more parts that can cooperate with each other to form the desired product shape. After the mold is closed, the plastic material (usually pre-made granules, powders, sheets or fibers) is placed in the mold cavity. The mold is then closed on a press, and pressure and heat are applied to make the plastic material melt, flow and fill all parts of the mold cavity. After a certain period of curing or cross-linking reaction, the mold is opened and the molded plastic product is removed.

Application fields of plastic compression molds

Plastic compression molds are widely used in electrical, automotive, aerospace, industrial, agricultural, transportation, chemical, construction, machinery and other fields. They can be used to manufacture electrical insulation parts, switch parts, automotive parts, aircraft, rockets and other key parts of aircraft.

Compression molding in the plastic industry is characterized by its capability to handle high production volumes and exert substantial pressure, which is essential for shaping intricate and robust fiberglass composites. It excels at forming sizable parts with complex geometries and is favored for its economical nature, as it uses materials sparingly, leading to low waste output.

Typical thermosetting plastics used for in plastic compression molding

In the compression molding process, commonly used thermosetting plastics include have Phenolic resin (PF),Urea-formaldehyde resin (UF),Melamine-formaldehyde resin (MF),Unsaturated polyester resin (UF),Epoxy resin (EP),Silicone resin (SI),Polyurethane.

Features of plastic compression molding moulds

- Dimensional stability: high dimensional accuracy and good repeatability of products.

- High surface quality: products with good surface finish can be produced.

- High production efficiency: suitable for large-scale production with high degree of automation.

- Material diversity: various thermosetting and thermoplastic plastics can be used.

- Design flexibility: products with complex shapes can be manufactured

Features of plastic compression molding moulds

With the advancement of science and technology, plastic molding technology is also developing continuously:

Efficiency

By optimizing the process flow and improving the mold precision, the molding efficiency can be further improved and the production cost can be reduced.

Intelligence

With the help of advanced automation equipment and control systems, the molding process can be intelligently managed to improve production efficiency and product quality.

Environmental protection

Environmentally friendly plastic raw materials and green production processes are used to reduce environmental pollution in the production process and achieve sustainable development

Advantages and Disadvantages of Plastic Molding Molds

Advantages

Small loss of raw materials, low internal stress of products, and stable mechanical properties.

Small wear of mold cavity and low maintenance cost of mold.

Can form larger flat products with high productivity.

High dimensional accuracy of products, smooth surface, no need for secondary modification.

Disadvantages

Long molding cycle and relatively low efficiency.

Not suitable for products with complex shapes or special structural features.

Mold manufacturing is complex and requires large investment.

The design and manufacture of plastic compression molds is a complex process that requires consideration of multiple factors, including material selection, mold structure design, temperature control, and post-processing processes. As technology develops, plastic compression molds will continue to play an important role in multiple industries.

The design and manufacture of plastic compression molds need to comprehensively consider the shape, size, function and use environment of the product, as well as the selection of mold materials, processing technology and cost. With the development of technology, the application of plastic compression molds in the manufacturing industry will become more extensive.