Detection Standards for Disposable Virus Sampling Tubes,In the ongoing battle against infectious diseases, especially in the context of global pandemics, the reliability and accuracy of virus sampling and detection are of paramount importance. Disposable virus sampling tubes have emerged as essential tools in this fight, serving as the first line of defense for healthcare workers and diagnostic laboratories. However, to ensure the effectiveness of these tubes, it is crucial to establish robust detection standards. In this blog post, we will delve into the world of disposable virus sampling tubes and explore the critical aspects of setting detection standards for these lifesaving devices.

Table of Contents

ToggleDetection Standards for Disposable Virus Sampling Tubes

1. Detection Standards for Disposable Virus Sampling Tubes

Disposable virus sampling tubes are designed for the collection, transportation, and preservation of clinical specimens, such as respiratory secretions, to aid in the diagnosis of viral infections. These tubes play a pivotal role in the accurate detection of pathogens, including viruses like influenza, SARS-CoV-2 (the virus responsible for COVID-19), and more. They are used extensively in clinical settings, diagnostic laboratories, and during public health emergencies.

2. Virus sampling tube testing requirements

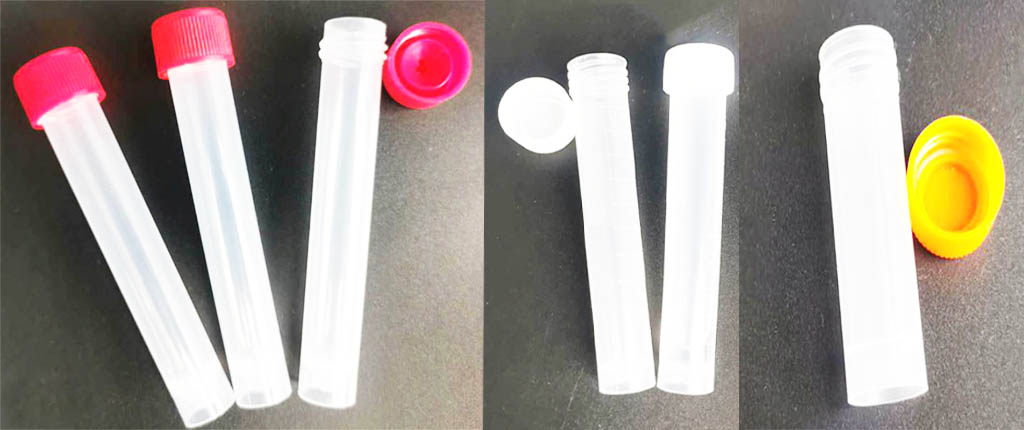

(1). Appearance: The outer packaging should be intact, the label should be complete, and the handwriting should be clear; the surface of the tube body should be smooth and smooth, without dirt, deformation, or cracks; the preservation solution should be clear, and there should be no visible foreign matter.

(2). Size: The virus sampling tube should conform to the marked design size and tolerance.

(3). Loading volume: The storage liquid loading volume should meet the requirements of the marked loading volume, and the deviation should be 0% to 10% of the marked value.

(4). Tightness: The tube body and cap of the virus sampling tube should be properly matched, and after the tube body and cap are tightened, they should have good airtightness.

(5). Acidity and alkalinity: The pH value of the preservation solution should conform to the marked value, with a tolerance of ±1.0.

(6). Microbial indicators: the total number of aerobic bacteria (CFU/mL) ≤ 200; the total number of mold and yeast (CFU/mL) ≤ 100.

(7). Virus preservation effect and virus inactivation efficiency: The manufacturer shall provide the virus preservation effect verification and virus inactivation efficiency verification documents.

3. Challenges in Virus Sampling and Detection

Before delving into detection standards, it’s essential to understand the challenges associated with virus sampling and detection:

Sample Contamination: Contamination risks during collection and transportation can lead to false positives or negatives.

Sample Integrity: Improper preservation and storage can degrade the sample, impacting the accuracy of results.

Sensitivity and Specificity: Detection methods need to be highly sensitive and specific to identify the virus accurately.

4. Key Components of Detection Standards

Establishing detection standards for disposable virus sampling tubes involves a comprehensive approach. Key components include:

Tube Design and Materials

Leakage Prevention: Ensuring airtight seals to prevent sample leakage during transportation.

Sample Preservation: Incorporating stabilizers to maintain sample integrity.

Sampling Procedure

Proper Training: Training healthcare workers in correct sample collection techniques to minimize contamination.

Detection Methodology

Validation: Rigorous validation of detection methods for sensitivity, specificity, and reliability.

Comparative Studies: Comparative studies to assess the performance of different tube designs and materials.

Virus sampling tube detection method

1. Appearance: Visually inspect the outer packaging of the sample, the surface of the tube body and the preservation solution, and the results should meet the requirements for virus sampling tube detection.

2. Size: use a general measuring tool to measure, and the result should meet the requirements for virus sampling tube detection.

3. Loading volume: use a general measuring tool to measure, and the result should meet the requirements of the virus sampling tube detection requirements.

4. Tightness: Unscrew the cap, pour out the preservation solution, and tighten the cap. Place the virus sampling tube in a container with an air extraction device, immerse it in water, and evacuate to a vacuum of 27kPa for 2 minutes. There should be no water ingress or bubbling in the tube, and the result should meet the requirements for virus sampling tube detection.

5. Acidity and alkalinity: Test according to the Pharmacopoeia of the People’s Republic of China 0631 pH value determination method. After the pH meter is calibrated with buffer solution, take 5 pieces of the preservation solution (5mL-10mL) of the test sample and pour it into a beaker and mix well, and measure its pH with a pH meter. After the readings are stable, read the pH value, measure the parallel samples with the same method, the error of the two measurements is ≤ 0.1, take the average of the two readings, and the results should meet the requirements of the virus sampling tube detection requirements.

6. Microorganisms: According to the Pharmacopoeia of the People’s Republic of China, Part 4 1105, the microbial limit of non-sterile products is checked; the membrane filtration method in the microbial counting method, after each filter membrane is rinsed with 500mL of washing liquid, the test is carried out according to the prescribed method, and the result should be consistent with the virus Sampling tube testing requirements.

7. Virus preservation effect and virus inactivation efficiency: The manufacturer should provide the virus preservation effect verification and virus inactivation efficiency verification documents. For inactivated virus sampling tubes, the verification document should include the time for effectively inactivating the virus, the conditions and maximum time for virus nucleic acid storage; for non-inactivated virus sampling tubes, the verification document should include the virus storage conditions and storage time.

8. Labels: At least the following contents or symbols should be on the package of each smallest sales unit

9. Instructions: There should be an instruction in each minimum sales unit, and the preparation of the instruction should comply with the provisions of GB/T9969.

Packaging: A single package should be the smallest package for use, and the smallest sales unit should be accompanied by an instruction manual, a quality certification mark or a product certification. Under the transportation conditions specified by the manufacturer, the packaging is not damaged, and the handwriting on the packaging label should be clear within the validity period.

Disposable virus sampling tubes are indispensable tools in the fight against infectious diseases. Establishing and adhering to robust detection standards is essential to ensure the accuracy and reliability of these critical devices. By addressing challenges, following regulatory guidelines, and embracing innovation, we can enhance the effectiveness of virus sampling and detection, ultimately contributing to better public health outcomes.