Factors Influencing Mold Surface Polishability.The surface finish of a plastic injection mold and composites material compression mould plays a crucial role in the quality of the final products it produces. Achieving a high level of polish on mold surfaces is essential for applications where aesthetics, precision, and functionality are paramount. However, mold surface polishability is influenced by a variety of factors that manufacturers need to consider. Let’s explore these factors in detail:

Factors Influencing Mold Surface Polishability

1. Mold Material

The choice of mold material significantly impacts its polishability. Some materials, like tool steels and certain aluminum alloys, can be polished to a very high degree due to their fine grain structure and smooth surface. Other materials, such as rougher cast metals, may not achieve the same level of polish.High-quality steel is an important for obtaining good polishing quality. Various inclusions and pores of steel will affect the polishing effect. To achieve a good polishing effect, the workpiece must be marked with the surface roughness of polishing at the beginning of machining. When a workpiece is determined to need mirror polishing, it must choose steel with good polishing performance and undergo heat treatment, otherwise it will not meet expectations. Effect.

2. Mold Surface Hardness

Harder mold materials tend to be more challenging to polish due to increased resistance to abrasion. While these materials offer excellent durability, achieving a high polish may require more time and effort.

3. Mold Surface Texture and Grain

The inherent surface texture and grain of the mold material can affect polishability. Materials with finer grains tend to be easier to polish to a smooth finish. However, coarse grains may make it more difficult to achieve a mirror-like polish.

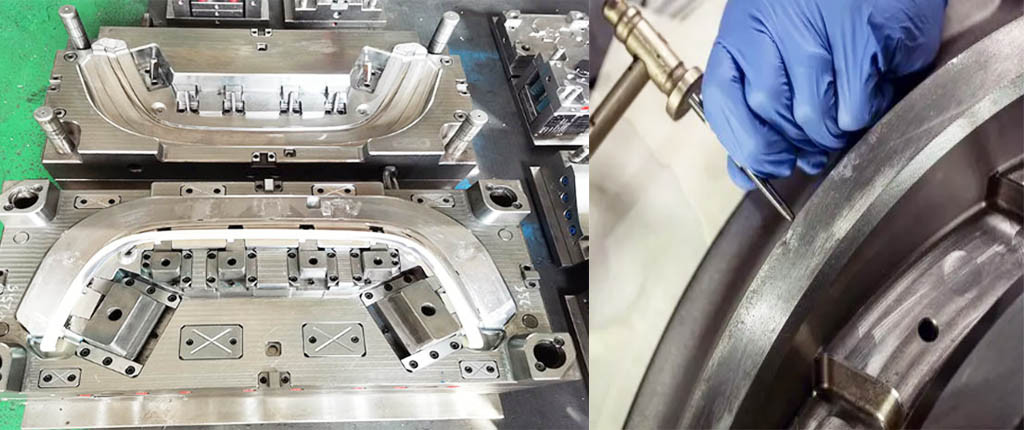

4. Mold Geometry

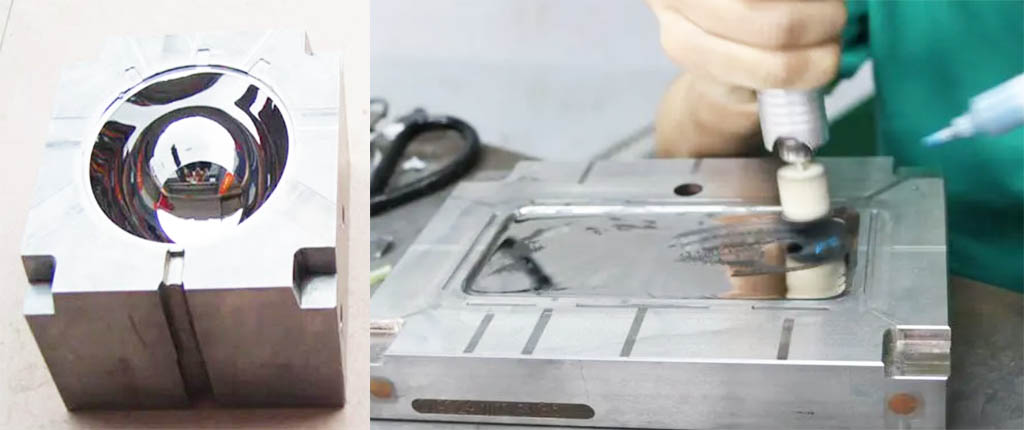

The complexity of the mold’s geometry can impact polishability. Molds with intricate designs, tight corners, and deep crevices may require specialized polishing techniques and tools to ensure uniform surface finish.

5. Mold Cooling Channels and Ejector Pin Marks

Move on to a fine-grit polishing compound to achieve a smoother finish. Fine polishing should help eliminate the finer scratches left by previous steps and bring out a higher level of shine.

6. Mold Surface Treatment

Previous surface treatments, such as nitriding or coatings, can affect how easily a mold can be polished. Some treatments may enhance the mold’s surface hardness but could require additional steps to achieve the desired level of polish.If the heat treatment is not appropriate, the hardness of the steel surface is uneven or the characteristics are different, which will cause difficulties in polishing.

7. Surface condition of workpiece

During the machining process of the material, the surface layer will be damaged by heat, internal stress or other factors, and improper cutting parameters will affect the polishing effect.

EDM surfaces are more difficult to grind than machined or heat treated surfaces, so EDM finishing should be used before the end of the EDM process, otherwise a hardened thin layer will form on the surface. If the EDM finishing standard is not selected properly, the depth of the heat-affected layer can be up to 0.4 mm. The hardened thin layer is harder than the matrix and must be removed. Therefore, it is good to add a rough grinding process so that provide a good foundation for polishing.

8. Mold Age and Wear

Over time, molds can develop wear, scratches, and imperfections due to repeated use. Older molds might require more extensive polishing efforts to restore their original finish.

9. Mold Polishing Techniques

The methods and tools used for polishing greatly influence the final surface finish. Proper selection of abrasive compounds, polishing pads, and techniques is essential to achieve the desired level of polish.Since polishing is mainly done manually, human skills are still the main factor affecting the quality of polishing.

10. Mold Operator Skill and Expertise

The skill level of the person performing the polishing is critical. Experienced polishers are better equipped to identify potential challenges and employ appropriate techniques to achieve optimal results.

11. Mold Budget and Time Constraints

The resources available for polishing, including time and budget, can impact the extent to which a mold can be polished. Achieving an extremely high polish may require more time, effort, and specialized tools.

12. Surface Imperfections and Defects

Molds with pre-existing imperfections, defects, or scratches may require additional effort to remove these blemishes during polishing.

In conclusion, achieving a high level of mold surface polishability involves a careful consideration of various factors, including the mold material, geometry, cooling channels, and the expertise of the polishing team. By addressing these factors and using appropriate techniques, manufacturers can produce molds that result in products with superior aesthetics, precision, and functionality.

In generally,polishing technology affects surface roughness. In fact, good polishing technology needs to cooperate with high-quality steel and correct heat treatment process to obtain satisfactory polishing effect; on the contrary, if polishing technology is not good, even if the steel is good, it will not be able to achieve a mirror effect.