Folding plastic crate mold technology,when it comes to plastic box manufacturing, mold technology is crucial. Plastic folding box mold technology plays a vital role in the logistics, storage, transportation and retail industries. This article will take an in-depth look at plastic folding box mold technology, understanding its importance and how it affects the production and logistics industry.

Table of Contents

ToggleFolding Plastic Crate Mold Technology

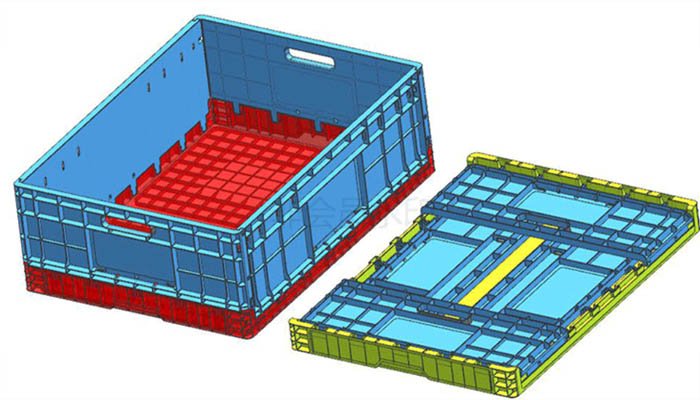

Folding plastic crate mold technology refers to the advanced methods and techniques used to create molds for collapsible plastic crates. This technology plays a crucial role in manufacturing efficient, space-saving, and durable crates for various industries.

The Importance of Folding Plastic Crate Mold Technology

1. The criticality of product design

The design of plastic folding boxes is crucial to mold technology. Appropriate design can make folding boxes more efficient during transportation and storage, reduce space occupation, reduce costs, and improve logistics efficiency.

2. Manufacturing cost

Mold technology can directly affect the manufacturing cost of folding boxes. A well-designed mold can improve production efficiency and reduce scrap rates, thereby saving production costs.

3. Quality Control

The accuracy and quality of the mold will affect the quality of the final product. A high-quality mold can ensure the dimensional consistency and structural strength of the folding box to meet the needs of different industries.

4. Customization and innovation

The mold technology of plastic folding boxes also allows customization and innovation. Manufacturers can develop unique designs and specifications based on customer needs to meet specific uses.

Key aspects of plastic folding crate mold technology

1. Mold Material selection

Mold technology should consider the plastic material used. Different materials have different properties, such as strength, wear resistance, chemical resistance, etc. Choosing the right materials is critical to the performance of your product.

2. Mold design

The design of the mold needs to consider the structure, shape and size of the folding box. This includes the hollow portion of the mold to allow the plastic to be injected and formed into the desired shape.

3. Cooling system

The mold requires an effective cooling system to ensure that the plastic can cool and harden quickly after injection. This helps increase production speed and reduce costs.

4. Automation technology

Modern mold technology also involves automation, such as automatic opening and closing of molds, mold temperature control and automatic discharge of finished products. These technologies increase production efficiency.

5. Maintenance and Repair

Molds require regular maintenance and repair to ensure their performance and longevity. This requires specialized knowledge and skills.

Application fields of plastic folding crate mold technology

1. Logistics and warehousing

Plastic folding boxes are often used in the storage, transportation and logistics fields of goods. They save space, reduce shipping costs, and improve inventory management efficiency.

2. Retail

In the retail sector, folding boxes can be used to display and store merchandise. They can be adjusted based on seasonality and sales needs, providing retailers with flexibility.

3. Agriculture

Plastic folding boxes are also widely used in the agricultural field. They can be used to store and transport produce to ensure product freshness and quality.

4. Manufacturing

In manufacturing, folding boxes are used for storage and transportation of parts. They can help reduce inventory costs and increase production efficiency.

Core tool for Large-Scale folding plastic crate Production

The plastic crate, derived from plastic pallets, is a spacious and versatile container ideal for factory logistics and product storage. It offers the advantages of folding, stackability, space efficiency, and cost savings. Primarily used in packaging, storing, and transporting a variety of items, from auto parts to textiles and produce, it serves as a highly adaptable logistics solution.

In recent years, with the continual growth in the number of retail enterprises and the scale of logistics distribution in our country, the utilization of logistics folding turnover boxes has significantly expanded. Consequently, the demand for storage space and operational areas has surged, leading to a widespread issue of turnover box losses. To address this challenge, an effective solution is required to minimize storage costs, prevent turnover box losses, and enhance overall logistics efficiency. The folding crate serves as an excellent solution to tackle these challenges.

Our company manufactures folding plastic crate using new PP and PE materials, enhancing their durability, impact resistance, and resistance to extreme temperatures. This extends the service life and substantially reduces storage and logistics costs. In all aspects, folding turnover boxes outperform traditional ones and are poised to replace them in the future market. They have found extensive use in closed-loop distribution systems, including major supermarket chains, 24-hour convenience stores, distribution centers, department stores, and various industries like clothing, home appliances, and food processing. Additionally, our folding turnover boxes can be pallet-stacked, facilitating mechanized handling, streamlining circulation, and significantly reducing storage and transportation costs for users.

In summary, plastic folding crate mold technology plays a key role in modern logistics, manufacturing and retail. Through carefully designed molds, appropriate material selection, and efficient production processes, manufacturers can improve product quality, reduce costs, and meet the needs of different industries. This makes plastic folding boxes an indispensable part of today’s supply chain and storage and transportation management.