Hot phenolic resin prepreg process widely used in compression molding production,hot phenolic resin prepreg (thermoset resin prepreg) is a material commonly used in the manufacture of composite materials. Prepreg refers to the state in which fiber reinforced materials (such as glass fiber, carbon fiber, etc.) have been impregnated in a resin matrix, but not yet cured. Thermal phenolic resins are thermosetting resins that cure at high temperatures to form hard, heat-resistant materials, making them suitable for composites used in high-strength and high-temperature environments.

Table of Contents

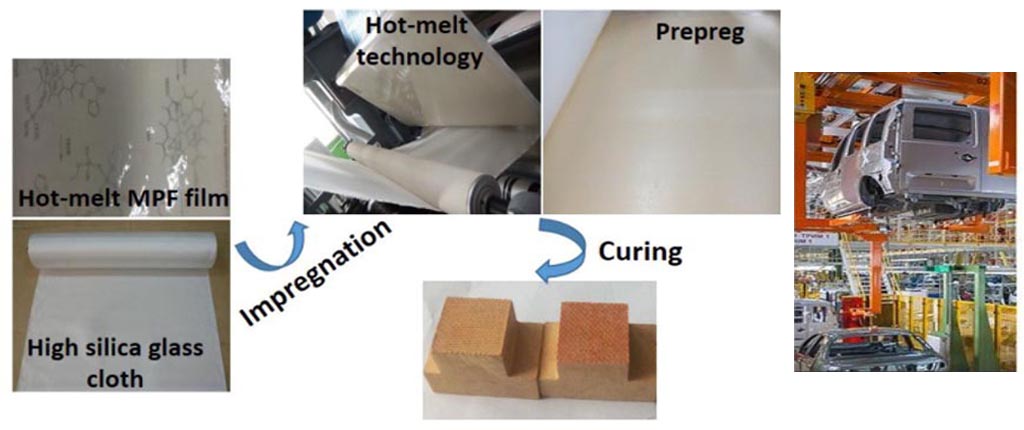

ToggleThe hot-melt film method is to melt the resin first, and then evenly coat the resin on the release paper to make a resin film. Finally, the carbon cloth is embedded in the resin film, and the prepreg tape can be obtained after pressing and cooling.

General Process Steps for Hot Phenolic Prepreg

1. Raw material preparation

Prepare the required hot phenolic resin, curing agent, solvent and fiber reinforcement materials (such as glass fiber cloth or carbon fiber cloth), etc.

2. Fiber pretreatment

Pretreatment of fiber reinforced materials, including removal of surface dirt, control of moisture content and orientation of fibers.

3. Impregnation

Impregnate the pretreated fiber reinforced material in hot phenolic resin to ensure that the resin fully penetrates between the fibers and forms a good bond between the resin and the fibers.

4. Extrusion or flattening

he impregnated fiber reinforced material is extruded or pressed to remove excess resin and air bubbles, so that the resin content of the prepreg is uniform.

5. Forming

Place the treated prepreg in the mold and form according to the design requirements.

6. Curing

Put the molded prepreg into a hot press or oven, and cure it under appropriate temperature and time conditions to completely harden the resin.

7. Cutting and processing

After the resin is fully cured, the composite material is cut and processed to meet the requirements of the final product.

The preparation process of hot phenolic resin prepreg needs to control parameters such as impregnation time, temperature and pressure to ensure the quality and performance of prepreg. In addition, pay attention to safety protection during operation and avoid contact with too much resin and toxic gases.

The specific process steps may vary depending on the manufacturing requirements, type of resin used and application of the composite material, and the above steps are for reference only. For the specific process in actual production, it is recommended to consult professional technicians or refer to relevant manufacturing guidelines.

The advantages of preparing prepreg tape by hot melt adhesive film method are:

(1). The hot-melt adhesive film method adopts solvent-free hot-melt processing, which can reduce the harm to the environment and operators.

(2). The thickness of the resin film is controllable, so the resin content in the prepreg tape can be precisely controlled.

(3). The porosity of the composite material prepared by the hot melt film method can be significantly reduced (no solvent is used, which greatly reduces the volatile content in the resin, which is conducive to the production of composite materials with low pore content and high mechanical properties) ).

(4). For the viscous body or resin film prepared from the resin matrix material, their technical indicators such as gel time and viscosity can be checked at any time, so that the quality of the prepreg can be strictly controlled. It can be seen that the preparation of prepreg by the hot melt adhesive film method not only avoids environmental pollution and personal injury, but also improves the quality of composite products, which is undoubtedly a low-cost and high-performance technology for advanced composite materials. an important development direction.

In view of the challenges and opportunities in the molding process of hot-melt resin and its composite materials, this project mainly discusses the resin matrix and the cured product of phenolic resin through the modification of the phenolic resin matrix and the comprehensive use of experiments, calculations and simulations. The correlation between the structure and the properties of the composite material, based on the study of the basic factors affecting the ablation resistance and mechanical properties of the composite material

Hot melt phenolic resin with the following characteristics

(1) Meet the hot melt process;

(2) The phenolic adhesive film can use the current curing process of wet-process phenolic resin-based composite materials;

(3) The hot melt phenolic resin-based composite material has excellent heat resistance and flame retardant properties;

(4) The mechanical properties of hot melt phenolic resin matrix composites are significantly improved.

Phenolic resin has the advantages of easy availability of raw materials, low price, simple production process and equipment, excellent heat resistance, mechanical properties, flame retardancy and good adhesion, cold resistance, electrical insulation, unique ablation resistance, etc., It has become an indispensable material in various industrial sectors. The preparation of prepreg tapes by hot melt film method (dry method) has attracted much attention in recent years.

Market prospects and applications of hot phenolic resin: rail transit, new energy,Military product industry, aerospace and defense, etc.;

Innovation point: Overcome the contradiction between poor film-forming property and high viscosity of phenolic resin.