How are medical device molds potential ? In the modern medical field, medical equipment molds play an important role. More than just molds for producing medical devices, they have enormous potential to improve patients’ quality of life, make healthcare more efficient, and advance medical science. This article will explore the potential of medical device molds and introduce their importance in the medical field.

How are medical device molds potential

Medical device molds are used in almost all medical device parts, ranging from hyperbaric oxygen chambers to hearing aids, pacemakers, etc. Due to the precision requirements for the production of medical equipment parts and components, medical equipment molds occupy an important position in the medical equipment industry.

1. Innovation and Customization

Medical device molds enable medical device manufacturers to innovate and customize. This means the development of medical devices that are more efficient, safer, and better suited to specific patient needs. By using highly precise molds, medical devices can adapt to different body shapes and needs, providing better treatment results.

2. Cost Effectiveness

Medical device manufacturing involves high R&D and production costs. Mold technology helps reduce these costs. Customized molds can reduce raw material waste and improve production efficiency, thus saving money. This enables manufacturers to offer more affordable medical devices while maintaining quality.

3. High precision and consistency

Products manufactured from medical device molds often require high precision and consistency. This is important for critical performance parameters such as surgical instruments or pacemakers. Mold manufacturing ensures that every piece of equipment meets the same high standards, reducing potential defects and errors.

4. Reduced risk of infection

The design of medical device molds can help reduce the risk of infection. The antimicrobial and easy-to-clean design prevents the growth of microorganisms, reducing the risk of infection for patients while using these devices. This is particularly important in surgical theaters and intensive care units.

5. Rapid response and new diseases

When new diseases or epidemics emerge, medical device molds can quickly respond to market demand. For example, during the COVID-19 pandemic, moldmakers were able to make molds for ventilators and protective gear to meet the sharp increase in demand. This capability is critical to safeguarding public health.

6. Sustainability

Sustainable design of medical device molds helps reduce reliance on limited resources and reduces environmental impact. By embracing renewable materials and sustainable production methods, moldmakers can advance the sustainability agenda in medical device manufacturing.

After summarizing the above, it is not difficult to see that the potential of medical equipment molds goes far beyond the production of medical equipment. They can promote medical innovation, reduce costs, improve quality, reduce infection risks, respond to emergencies, and promote sustainable development in the medical field. Therefore, medical device molds play a key role in the modern medical field, providing a better future for patients and healthcare.

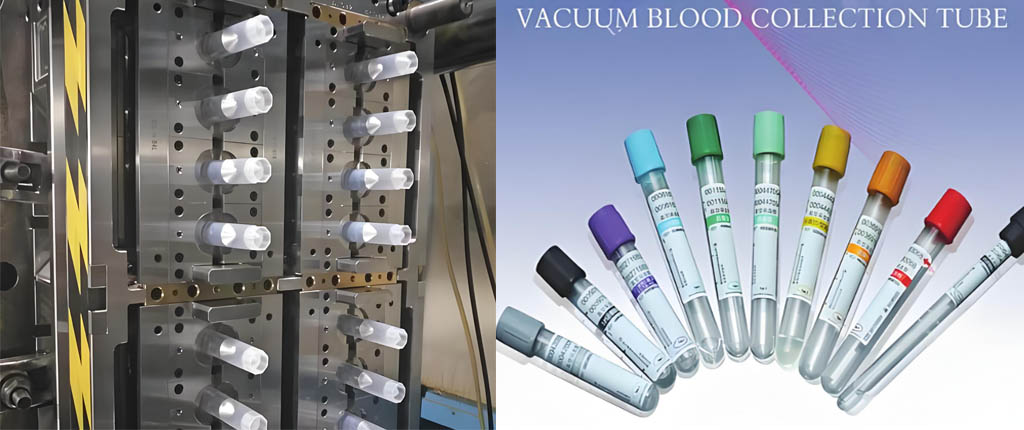

At present, my country only accounts for 2% of the world’s share of medical device molds, and the consumption ratio of drugs and medical devices is only 2.5:1, while the developed countries are 1:1; the per capita annual consumption cost of medical plastics in the United States is 300 US dollars, while China’s Only 30 yuan, showing great potential for development.

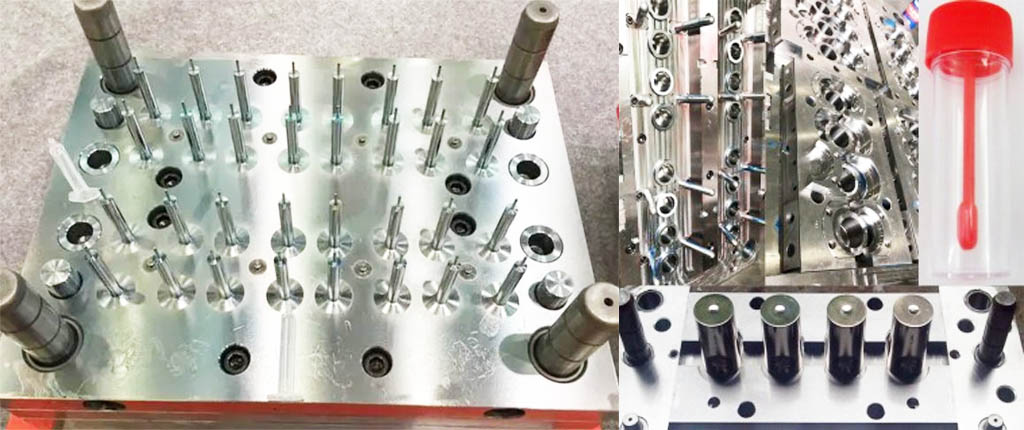

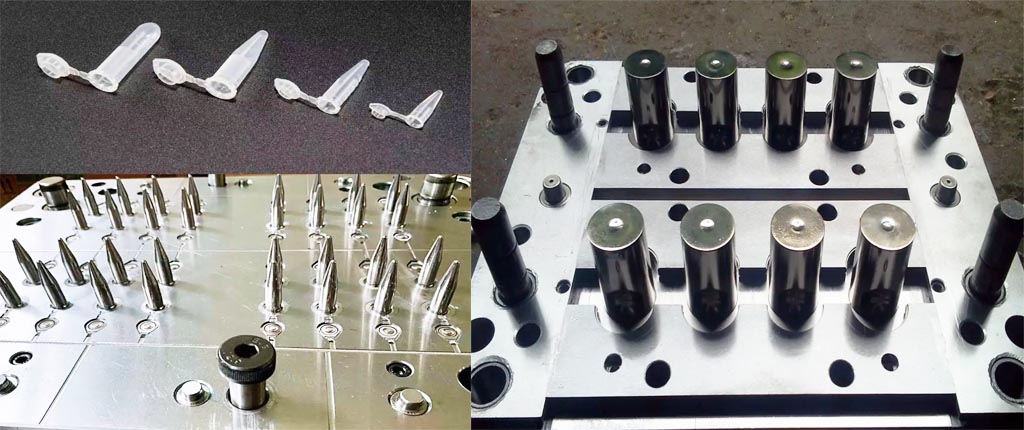

The laboratory consumable molds we can produce include nucleic acid extraction tube molds, virus detection card molds, virus sampling tubes, precision medical molds, medical molds, medical device molds, centrifuge tube molds, tip molds, PCR molds.

Taizhou WS(WINSEN) MOLD company focuses on the research and development of precision molds and product processing for disposable medical consumable plastic products moulds, and can design and manufacture various molds according to customer requirements. The company has a group of mold engineers who have been engaged in mold manufacturing for more than 20 years, as well as experienced product designers. The company has complete production equipment, thoughtful service, punctual delivery, quality assurance and reasonable price. Our company’s business philosophy: win customers by integrity, seek long-term cooperation by quality. Welcome customers and friends to inquire and cooperate.