How to Maintain Plastic Injection Mold ? Regular maintenance of the mold and keeping the machinery, raw materials and workshop clean help to ensure the normal progress of mold making, so how to maintain it? WS Mould will give you a brief introduction.

Table of Contents

ToggleHow to Maintain Plastic Injection Mold

Keeping the parison head clean is an important prerequisite for extrusion blow molding of high-performance products. Streamlined or chrome-plated mold runners can reduce the appearance of parison streaks.

When the expanded parison is in contact with the mold cavity, the temperature is high, which can To properly offset the impact of the parison stripes on the appearance of the product, several methods for cleaning the machine head are introduced below.

1. Manual cleaning method

Before disassembling the machine head, use an electric heater to heat it above the melting point of the plastic. The acetylene flame cannot be used for heating, because it affects the size and shape of the mold and the mandrel, which will cause local overheating and warping of the mold. Remove the heater and remove the handpiece for cleaning. The melt on the machine head can also be removed by high-speed air flow, but the oxidized melt still needs to be wiped off with brass cotton. When manually cleaning the machine head, avoid scratching the runner, especially the mold area, the workload of this method is Large, can cause physical and often metallurgical damage to the metal on mold runner walls.

2. Solvent cleaning method

That is to say, cleaning is performed by acidic or alkaline chemical substances, organic or inorganic solvents, wherein the acid or alkali chemical cleaning method has low equipment cost, but high chemical cleaning cost and low cleaning efficiency.

3. Ultrasonic cleaning method

This method has good cleaning effect, but has high equipment and chemical costs, and has corrosion problems. It is best used for post-cleaning to remove inorganic residues. In addition, there are cleaning methods such as salt bath, oven or fluidized bed.

Mold maintenance

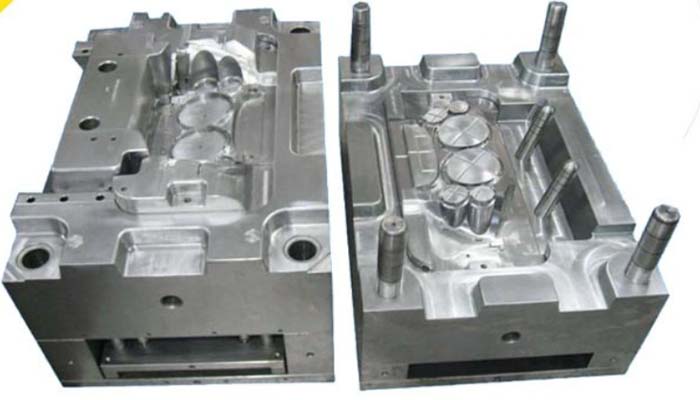

Plastic injection molds are made for producing a large number of identical plastic parts. As these molds are typically made from hardened steel or aluminum, they require proper maintenance to ensure prolonged life and optimum performance. Here are some tips for maintaining plastic injection molds:

1). Clean the mold regularly: The mold should be cleaned regularly to remove any dirt or debris that may accumulate inside. This can be done with a soft brush, compressed air or with a cloth.

2). Lubricate periodically: Lubrication is critical for keeping the mold functioning correctly. Apply a thin layer of grease or oil to all the moving parts such as the ejector pins, guide pins, and bushings.

3). Inspect regularly for wear and damage: Regularly examine the mold for any signs of damage, wear or warping. The most common issues are surface scratches, cracks or pitting. Be sure to inspect the mold body, cavities, and cores.

4). Repair or replace any damaged parts: if any parts show signs of damage or wear, replace them immediately or repair as soon as possible. Be sure to use parts that match the original design specifications to ensure proper functionality.

5). Store the mold carefully: When not in use, plastic injection molds should be stored properly to prevent corrosion, rust or contamination. A dry, cool place such as a climate-controlled storage area helps to maintain the condition of the mold.

By following these maintenance tips, plastic injection molds can operate excellently for the long term, and produce high-quality parts more consistently.

The cavity of the mold should be highly polished, and it should be polished regularly during the production process. Polish the cavity with polishing agent and tissue paper. A small amount of polishing agent penetrates into the surface of the cavity, and then polish the cavity with clean tissue until a mirror surface appears. The tissue paper should be replaced frequently when polishing to avoid scratching the mold cavity, skilled molding workers should repair the worn clamping edges of the mold, and the guide posts and guide sleeves of the mold should be regularly lubricated to ensure the two mold halves are aligned and extend the life of the mold , Whenever production stops or blow molds need to be stored, compressed air should be used to blow out the cooling channels of the mold, and a protective agent should be applied to the mold cavity to avoid corrosion.