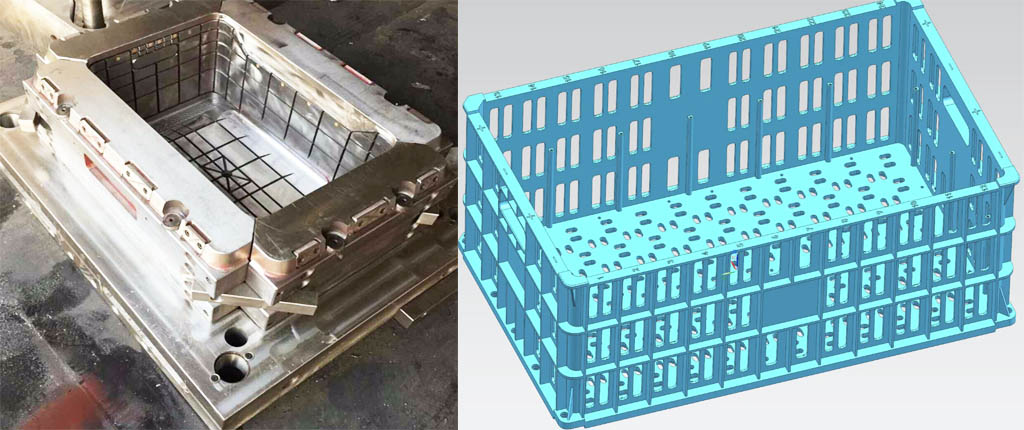

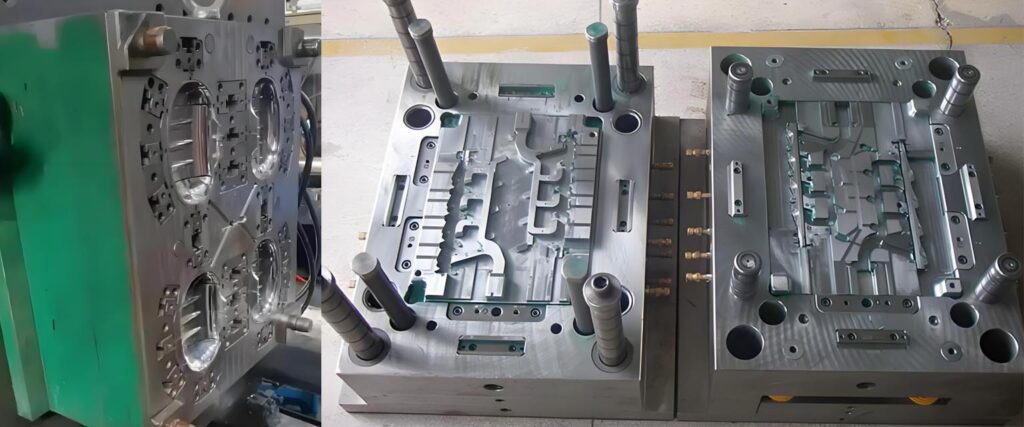

How Turnover Basket Molds Save Space and Costs? In the world of logistics and materials handling, space optimization and cost reduction are paramount. Plastic Injection Turnover basket molds have emerged as a game-changer in this regard. These versatile tools not only streamline operations but also offer substantial savings. In this blog, we’ll delve into the ways in which turnover basket molds can help businesses save space and cut costs.

Table of Contents

ToggleHow Turnover Basket Molds Save Space and Costs

The turnover basket, often referred to as the plastic basket due to its primary construction material, plays a significant role in various industries. These versatile containers are commonly used in industrial assembly line circulation and storage stacking, and they are often regarded as essential assets alongside turnover boxes and pallet boxes. In recent times, the utilization of turnover baskets has extended to the agricultural sector, gradually replacing traditional bamboo baskets for storing fruits and vegetables. This shift highlights the adaptability and efficiency of these plastic baskets in diverse applications.

1. Maximizing Storage Space

One of the primary benefits of turnover basket molds is their ability to maximize storage space. Traditional containers can be bulky and inefficient, taking up valuable real estate in warehouses and storage areas. Turnover baskets, on the other hand, are designed with stackability in mind. Their nestable design means they can be easily stacked when not in use, saving significant floor space. This space-efficient feature enables businesses to store more products in the same footprint.

2. Reducing Transportation Costs

Turnover basket molds also contribute to significant cost reductions in transportation. Their lightweight yet durable construction means they weigh less than many alternative containers. This reduced weight translates into lower shipping costs, as companies can transport more goods in a single shipment without exceeding weight limits. Additionally, their stackability simplifies loading and unloading processes, which can further reduce handling costs.

3. Enhancing Product Protection

Not only do turnover basket molds save space and reduce costs, but they also provide enhanced protection for the goods they contain. Their durable materials and robust construction shield products from damage during handling and transport. This, in turn, lowers expenses related to product replacement and repair.

4. Sustainable and Eco-Friendly

Modern businesses are increasingly concerned with sustainability and environmental impact. Turnover basket molds can contribute to a company’s eco-friendly initiatives. Many of these molds are made from recyclable materials, reducing the environmental footprint. Furthermore, the longevity of these molds ensures fewer disposals and replacements, aligning with sustainable business practices.

5. Versatility and Adaptability

Turnover basket molds are designed to be versatile and adaptable. They can be customized to meet specific needs and are suitable for various industries, from agriculture to manufacturing. Their flexibility extends to the types of products they can hold, making them ideal for both delicate and robust items.

Turnover basket classification

Turnover baskets come in various configurations, including mesh stackable, mesh coverable, and closed coverable types, each designed for specific industrial applications. Mesh stackable baskets are ideal for stacking purposes, while the coverable types are not meant for stacking but offer space-saving advantages post-use. Mesh baskets are suitable for stacking solid items, while closed containers can accommodate both solid and liquid items. In addition to their design, turnover baskets can be categorized into general turnover baskets and anti-static turnover baskets based on their performance characteristics. These distinctions enable businesses to choose the most suitable options for their specific needs.

The characteristics of the turnover basket

Turnover baskets offer a combination of economic advantages, environmental friendliness, hygiene, safety, and convenience. They are not only cost-effective and recyclable but also contribute to ecological preservation. These baskets are designed to be hygienic, resisting acid and alkali, preventing mold, moisture, and pests. They are a safe choice, free of nails, radiation, non-toxic, and odorless. Their hassle-free maintenance and easy handling make them a convenient choice. As the global economy continues to evolve and the agricultural industry expands in the new era, turnover baskets will play an increasingly pivotal role in supporting economic growth and sustainability.

In a world where efficient space utilization and cost reduction are key to success, turnover basket molds have proven their worth. By maximizing storage space, reducing transportation costs, enhancing product protection, and embracing sustainability, these molds offer businesses a multifaceted solution. As companies continue to seek ways to streamline operations and boost profitability, turnover basket molds are emerging as a valuable asset in the world of logistics and materials handling. They are not just containers; they are cost-saving, space-efficient, and sustainable solutions that make a real difference in today’s competitive business environment.