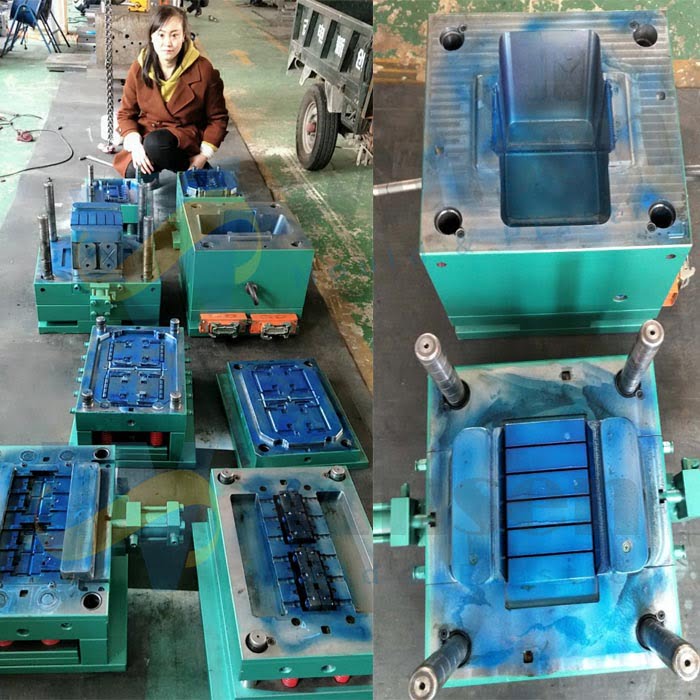

Plastic Injection Battery Box Mold

WS Mold is top on new energy battery box mold for various types and specification, a reliable plastic injection battery box mold manufacturer in China

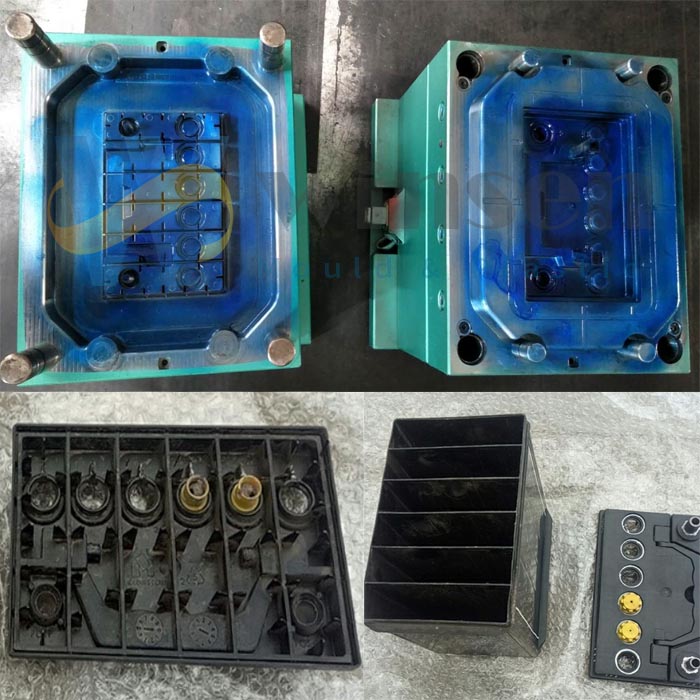

Plastic Injection Battery Box Mold Maker

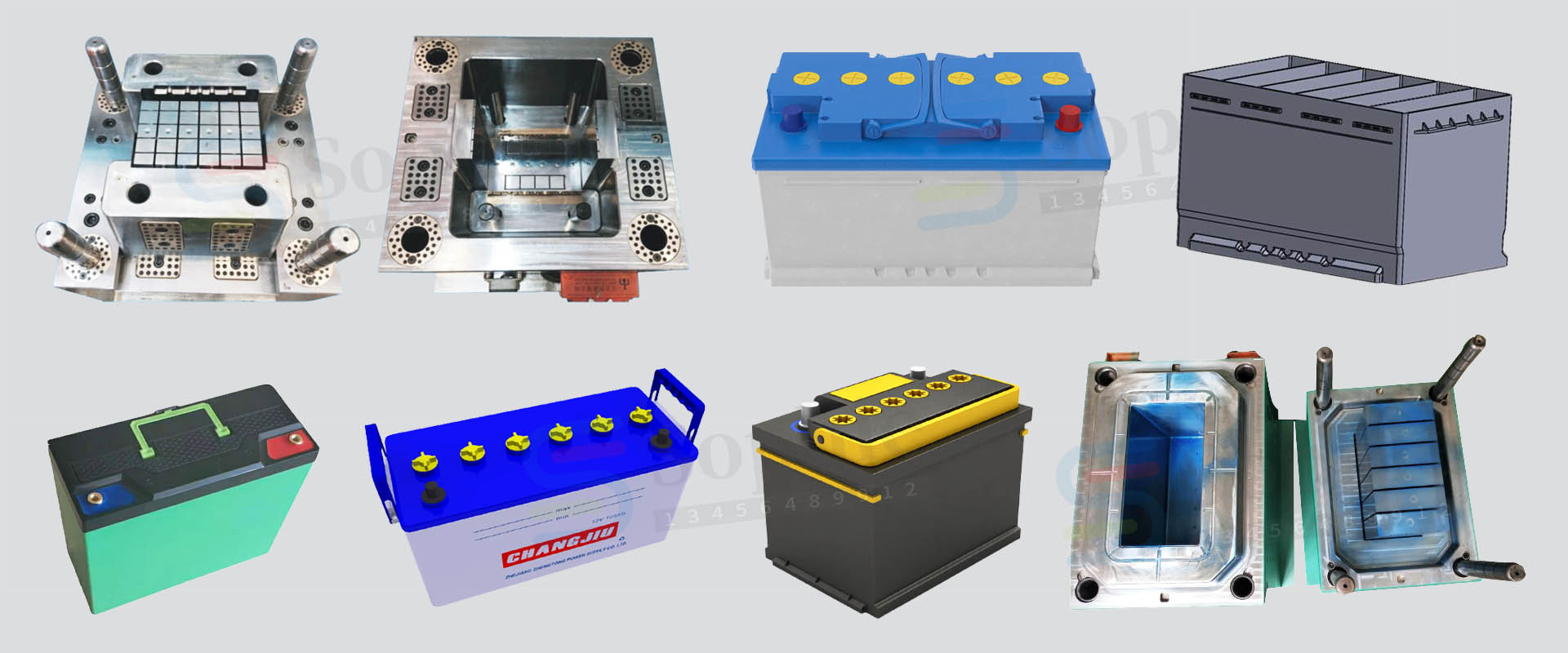

WS Mold is professional for new energy plastic injection battery box mold design and manufacturing. We have more than 20 years of experience in battery box and lid mold making. The battery box molds we produced contain automotive battery box series have Japanese vehicles standard N40, NS40, N50, NS60, N70, NS70, N90, N100, N120, NS120, N135, N150, N165, N180 and N200; UPS battery series like 55AH, 90AH, 100AH; Invertor battery series like IT 500; DIN battery series like DIN55, DIN66; Also have Europe vehicles standard LB1/L1, LB2/L2, LB3/L3, L4 and L5, any other types of plastic battery box mold customized according to customer requirements.

Plastic Injection Battery Box

Auto Battery Container

Plastic Injection Battery Shell

Plastic Injection Battery Case

Plastic Battery Box Mold

Automobile plastic injection battery box mold manufacturer, to create your own plastic battery box mold boutique mold, long mold life, stable quality.

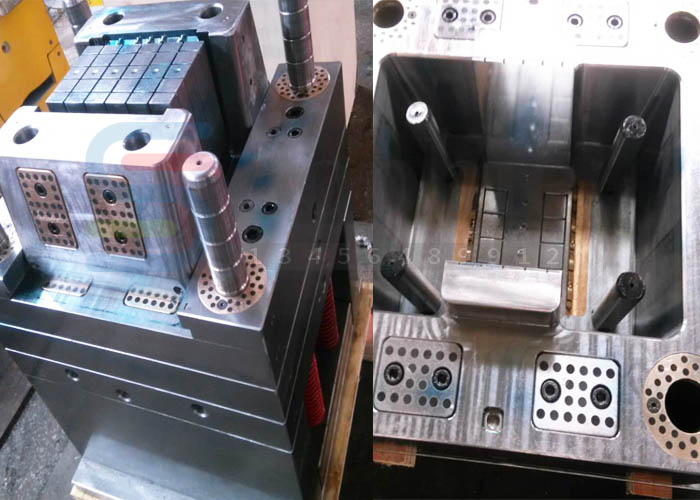

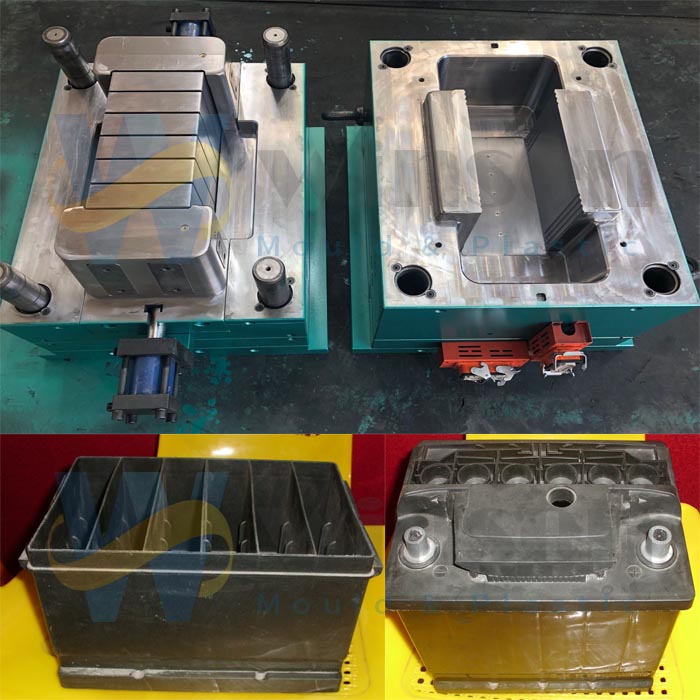

Auto Battery Container Mold

Auto Battery container Mold is widely used in the auto industry, it has many different models, such as N40, N50, N70, N100, N150, N180, L1, L2, L3, L4, L5.

Automobile Battery Shell Mold

Automobile Battery Shell Mold is usually made by P20H and H13 steel,and use the hot runner method, which can save waste and improve production efficiency.

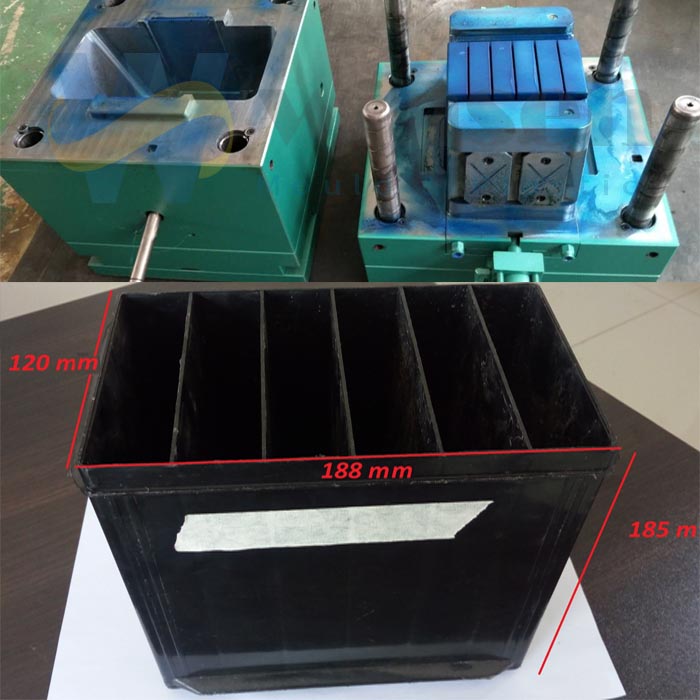

Plastic Battery Case Mold

PP plastic car battery case mold professional maker,many different model and size injection battery case molds are available.

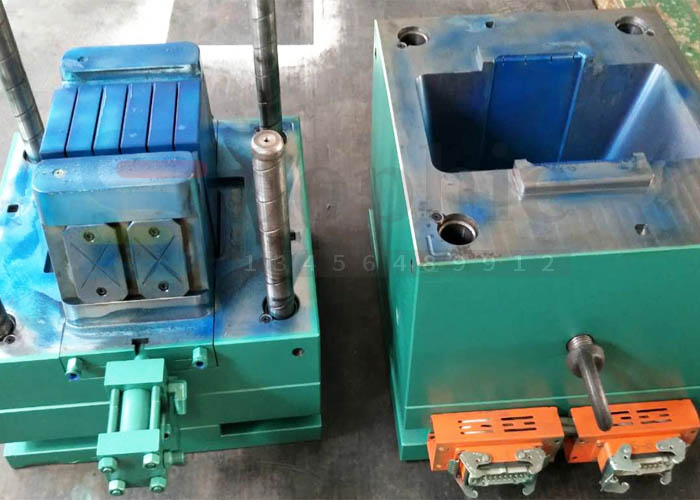

Car battery container mold

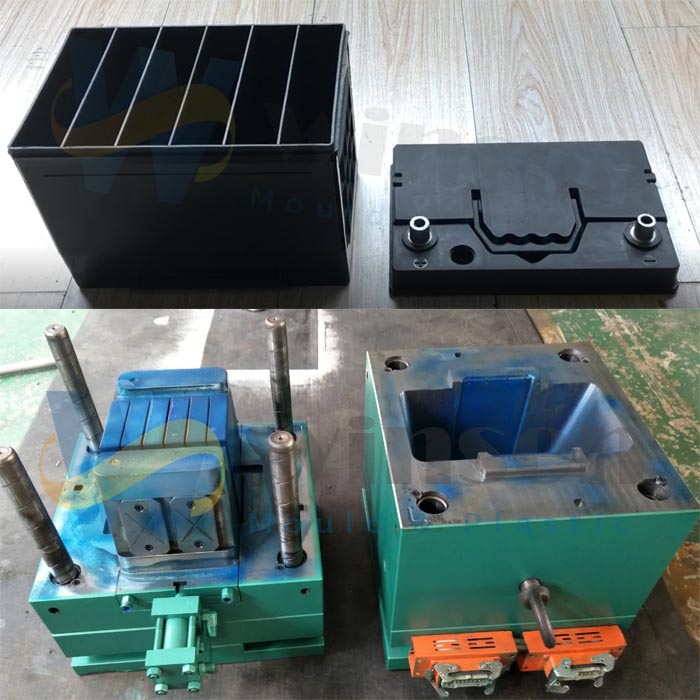

A complete set of plastic car automotive battery container molds includes battery box body molds, lid molds, handle molds, plug molds, etc.

Battery Box Cover Mold

The battery box cover mold is one of the parts of the battery box mold. There are many types of battery container covers.

Plastic Injection Battery Box Handle Mold

plastic battery box handle mold for battery container, it will make by 4 cavities mold or 8 cavities handle molds by hot runner or cold runner.

Plastic Injection Battery Box Lid Plug Mould

Generally, we make Battery box lid plug mold with 12 or 24 cavities,It is recommended to make a hot runner mold for injection molding

Car Auto Battery Box Mold

Plastic Battery Container Injection Mold

Automobile Battery Shell Mold

Automobile Battery Plastic Case Mold

Contact Us For More Technology

The battery box produced by the battery box mold is widely used in automobile industry, welcome to contact us for more information about the plastic injection battery box mold technology..

Why are battery box molds popular

New energy vehicles are becoming more and more popular at present, and the demand for battery boxes is also increasing, so battery box molds have become popular.

Car battery box will protection from leaks or explosion for vehicles. A battery box is installed on the vehicle floor in an area behind the rear tire in race applications.

We can provide one-stop service from Battery Box Mould design to manufacturing, to final product injection molding, saving customers’ cost and time, our company produces a series of auto parts molds, welcome to consult.

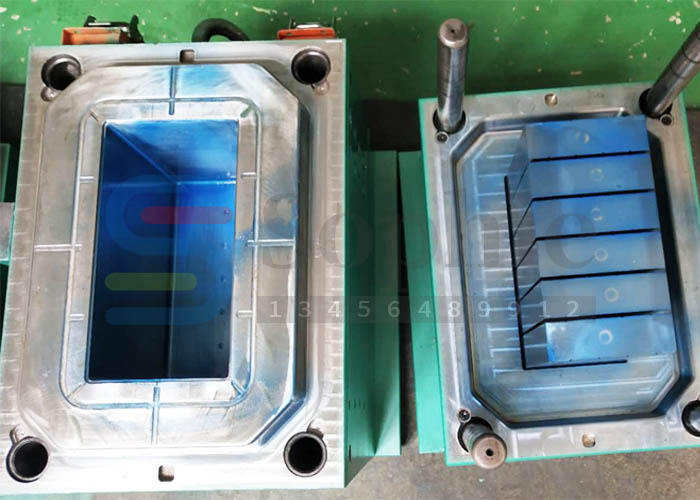

Basic features of battery box mold

Mould Name: Plastic injection Battery Box case Mould

Product size: All kinds of specification

Cavity: 1 cavity

Mould main material: H13 and P20 H

Mold injection system: 7 point hot runner

Mold ejection system: ejector plate

Mold cycle time: 30-45S

Delivery time: 50 working days

Mould Features: Have a good cooling system and stable injection production.

WS is a professional manufacturer of automotive battery box case shell molds in taizhou China. Various models and specifications of battery container molds can be customized.

Battery box is container or case that surrounds the car automotive battery. It can be made of plastic PP and ABS material.

Battery box is container or case that surrounds the car automotive battery. It can be made of plastic PP and ABS material. The function of auto battery box is to protect the battery and the vehicle in the event. It also can protects the battery from the elements and possible damage in an accident.

We use digital mold technology to design and manufacture the battery box mold. In recent years, many domestic mold companies have begun to apply digital mold technology to mold development, design, manufacturing and testing, which has improved the reliability of mold design, shortened the mold development cycle, and achieved good results. good economic benefits. It is expected that digital mold technology will gradually become the mainstream technology of mold manufacturing, and will be adopted by more mold enterprises.

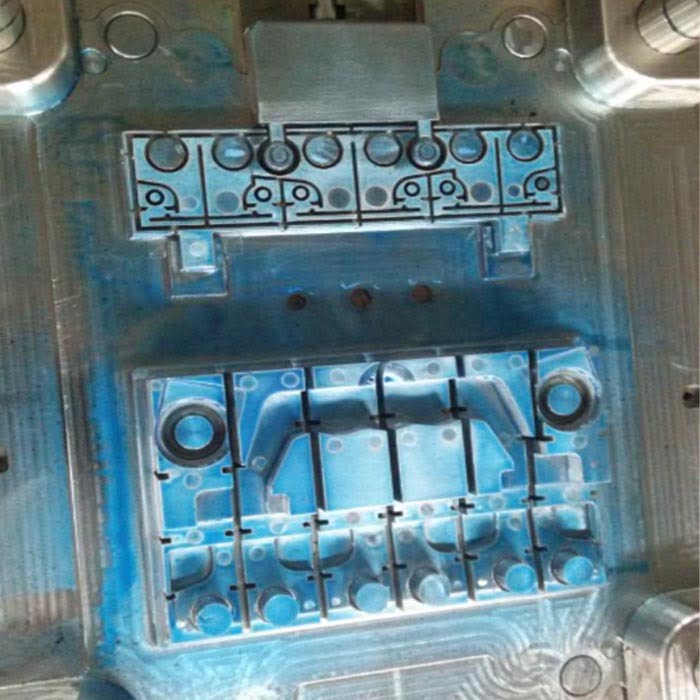

Introduction of car battery box cover mold

The battery box lid mould is one of the parts of the battery box mold. There are many types of battery container covers. There has one cover as a whole, and there are 2-3 covers welded together. No matter which type of lid molds, we can make it and help you provide professional services for Battery Box Lid Mould Plastic Injection Battery Container Cover Mold.

WS MOLD is offering plastic injection mould for Battery box lid,battery container cover mold supplier in huangyan.

The battery box lid molding can generally be make as a 1 cavity mould, 2 cavities molds, using a hot runner or a cold runner injection. For the battery container cover mould of 2 small cover welding type, the small cover can be make a 4 cavities molds.

We produce dozens of sets of battery box moulds every year, which are sold at home and abroad, and are deeply recognized and appreciated by customers.

WS is located in the beautiful East China Sea “Mold Town” – Huangyan, Zhejiang. It is a mold manufacturer mainly focusing on plastic injection molds.

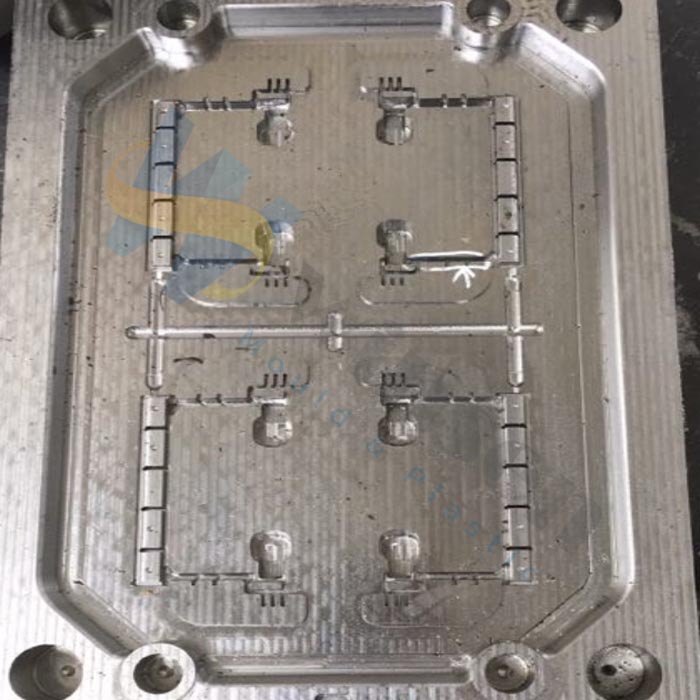

Battery Box Handle Mold Plastic Battery Container Case Handle Injection Mold

We are a factory specializing in the design and manufacture of plastic injection molds, and we are quite experienced in Plastic Battery Container Case Handle Injection Mold. The company recruits talents from all walks of life, including mold engineers with rich experience in Huangyan, as well as senior engineers and managers from other places, to provide customers with high-quality handle molds at reasonable prices. Our molds have been exported to Europe, America, Japan, and South Korea. , some countries in Africa and the Middle East.

The company will serve our customers wholeheartedly with new thinking, new concepts and new technologies. We warmly welcome customers at home and abroad to visit us, and we would like to express our gratitude to customers who have always supported and cared for our company!

Battery Box Lid Plug Mold Plastic Injection Mold For Battery Container Cover

We have made various plug molds for battery container cover,We will provide a complete set of injection molding solutions according to customers’ budget plans and needs. Standard injection mold, 1 year free warranty.

Don’t look at the small plug, but the mold is very complicated to make. If it is not professionally produced, there will be the risk of mold scrapping.We produce many plug moulds every year and have enough experience to provide you with a successful production.

Welcome to inquire, come to drawings and sample processing.

Our molds always adhere to the belief, and do our best to combine design and multiple quality assurance, and perfectly express the interpersonal relationship and the adaptability of the times.

Welcome to inquire, come to drawings and sample processing.

Our molds always adhere to the belief, and do our best to combine design and multiple quality assurance, and perfectly express the interpersonal relationship and the adaptability of the times.