Plastic PVC Junction Box Molds for Electrical Solutions

Precision PVC Junction Box Molds to elevate Electricals,Safeguard Wiring,Plastic Electrical Junction Box Injection Mold is Cornerstone of Electrical Infrastructure

WS MOLD specialize in crafting high-quality injection mold Plastic PVC Junction Box Molds that are designed to meet the rigorous demands of the electrical industry. Our molds are precision-engineered for durability, safety, and ease of installation.

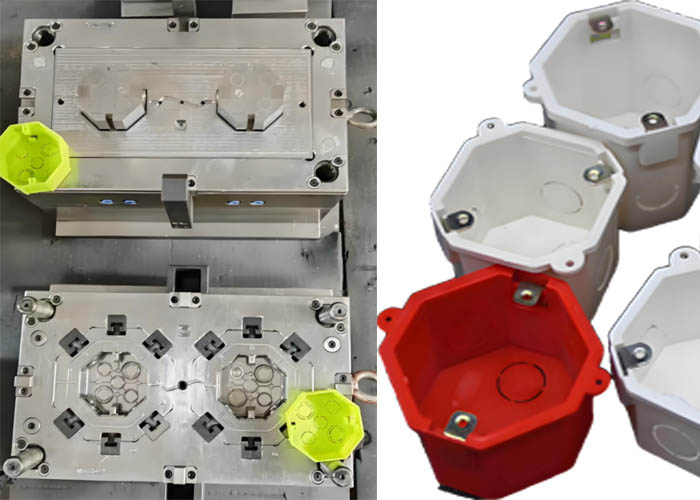

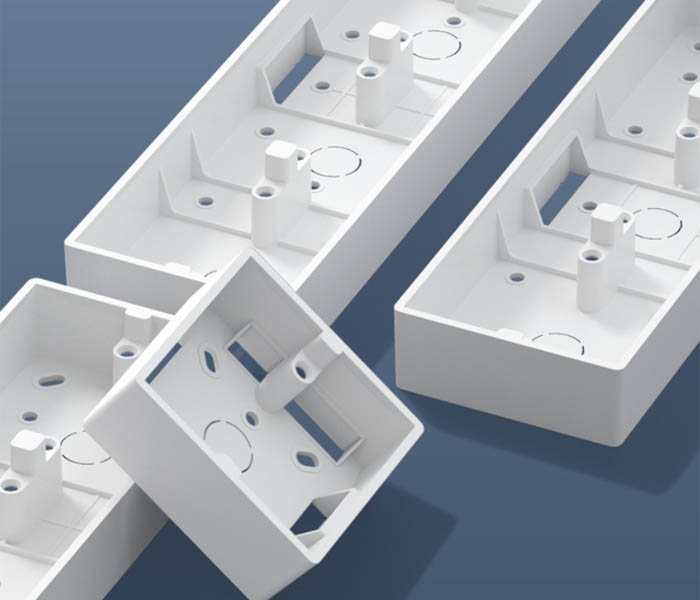

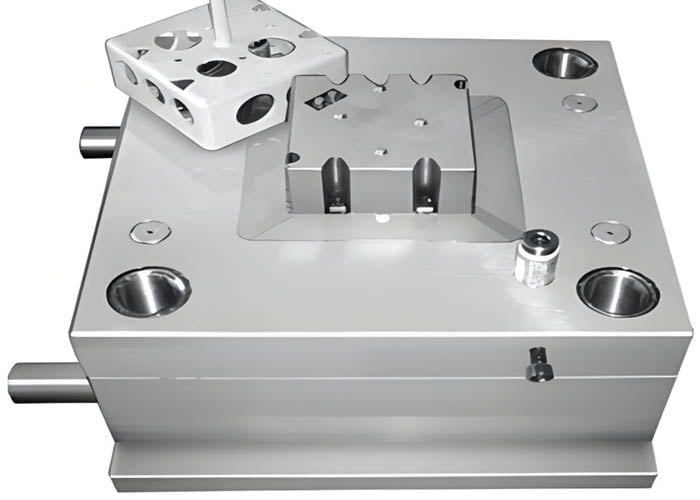

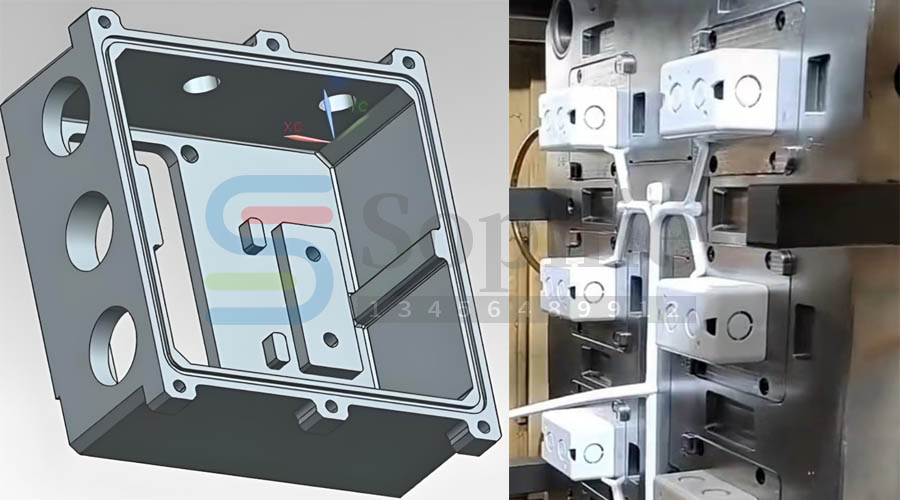

PVC Junction Box Mold

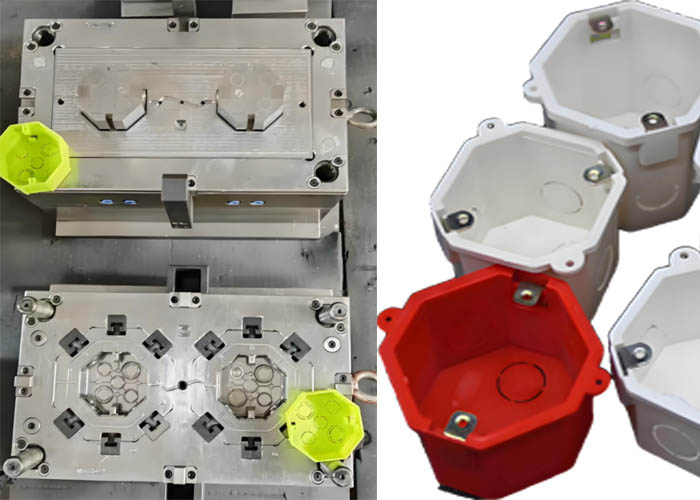

Plastic Junction Box Mold

Electrical Junction Box Mould

What is PVC Junction Box Mold

PVC Junction Box Molds are a tool used to manufacture plastic junction boxes.These molds are produced through injection molding to produce junction boxes used in protect wire connections in electrical installations. It is usually made of polyvinyl chloride (PVC) material with good insulation and corrosion resistance,which is widely used in the electrical field due to its insulation properties and corrosion resistance.

PVC electrical junction boxes offer a cost-effective and user-friendly solution for electrical installations. The lightweight nature of these boxes facilitates easy handling and installation, with the added benefit of simple hole punching on the back or sides for wiring access. Additionally, the inclusion of integrated wire clamps in many models contributes to a more economical project, streamlining both the process and the overall expenses.

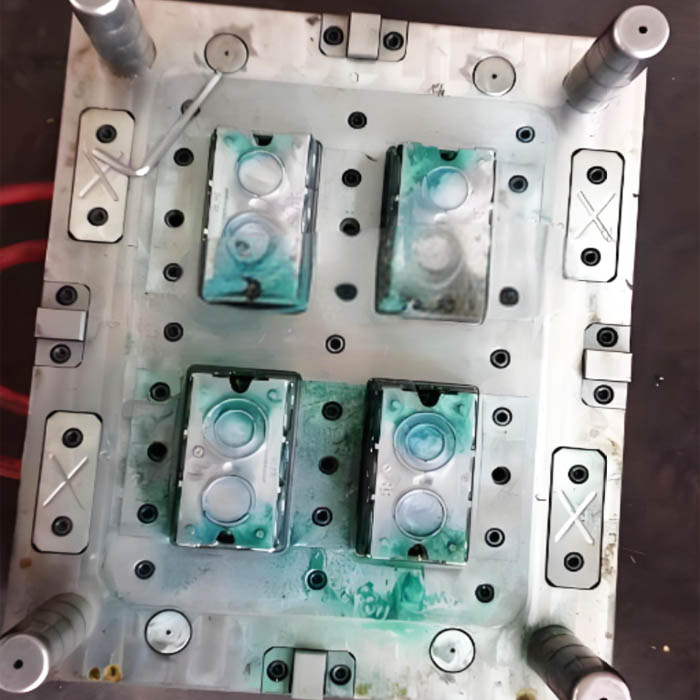

To achieve the necessary levels of dust and water resistance, such as IP66 or IP67 ratings, junction boxes are often manufactured using a dual-injection molding process. This method ensures a sealed design that meets stringent dustproof and waterproof specifications.

In the market, the dimensions that are frequently in high demand for plastic junction boxes as follows:

Small junction box

40mm x 40mm x 20mm

50mm x 50mm x 30mm

Medium junction box

60mm x 60mm x 40mm

80mm x 80mm x 50mm

Large junction box

100mm x 100mm x 60mm

120mm x 120mm x 80mm

Deep junction box

150mm x 150mm x 100mm (larger depth, suitable for more wiring needs)

Other special sizes, depending on specific projects or customer requirements, there may be other non-standard sizes.Above size reflecting their popularity for various electrical applications.

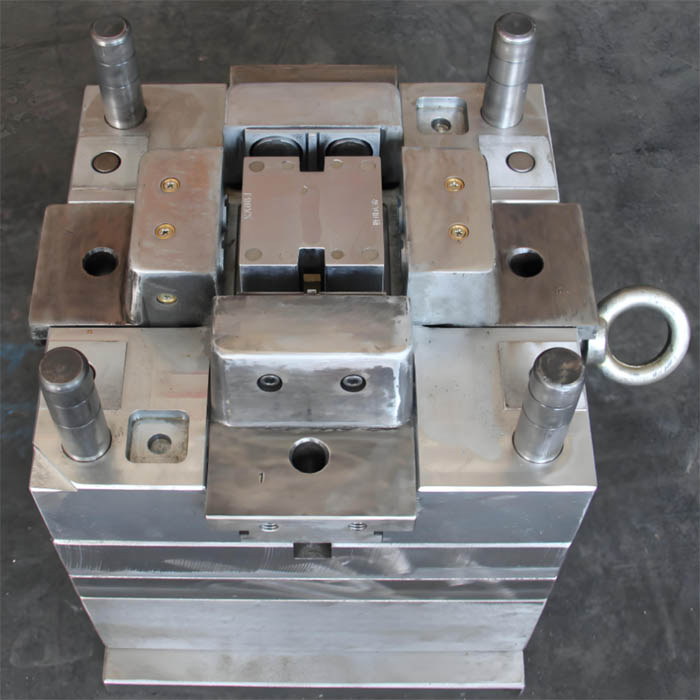

PVC Junction Box Molds Technical Specifications

PVC Junction Box Molds technical specifications usually include the following key aspects:

- Material: PVC junction box molds are usually made of high-quality steel, such as “DIN 1.2316, DIN 1.2738, DIN 1.2344, M300, 718, P20”, etc.

- Number of mold cavities: It can be a single-cavity or multi-cavity design to meet different production needs.

- Mold size: The specific size of the mold will depend on the required size of the junction box, for example, the mold may be suitable for 450T Injection Molding Machine.

- Surface treatment: The mold surface may undergo processes such as “Diamond Polish” to ensure the surface quality of the molded part.

- Mold life: The design life of high-quality PVC junction box molds can reach 500,000 ~ 1,200,000 shots.

- Mold design software: Software such as “UG, Proe, CAD” may be used in the design process.

- Delivery time: The time from mold order to delivery is usually within the range of 35-75 work days.

- Mold accessories: The accessories used in the mold meet the standards of DME, HASCO, LKM and so on.

- Cooling system: The mold may be equipped with “In core baffle cooling and in cavity plate chain drilling type cooling” system to ensure the efficiency of the molding process.

- Mold manufacturing culture and service: The manufacturing process focuses on responsibility and quality control to ensure the precision and durability of the mold.

These technical specifications ensure that PVC Junction Box Molds can meet the high standards of the electrical industry, while ensuring high efficiency of production and high quality of products.

PVC Junction Box Application Areas

PVC Junction Boxes are widely used in a variety of fields, mainly due to their durability, cost-effectiveness, and ability to protect electrical connections. Here are some of the main application areas of PVC Junction Boxes:

Industrial Environments

PVC Junction Boxes play an important role in industrial environments. They are often used to protect wire connections, switches, and other electrical equipment to ensure safety and reduce electrical hazards.

Commercial and Industrial Buildings

In commercial and industrial buildings, such as offices, factories, warehouses, and retail spaces, PVC Junction Boxes are used as reliable enclosures for lighting systems, switchboards, control circuits, and machinery.

Hazardous Environments

In commercial and industrial buildings, such as offices, factories, warehouses, and retail spaces, PVC Junction Boxes are used as reliable enclosures for lighting systems, switchboards, control circuits, and machinery.

Outdoor Applications

Due to the excellent resistance of PVC material to environmental factors, PVC Junction Boxes are ideal for outdoor use, such as outdoor lighting systems, irrigation systems, and landscape installations.

Special Applications

In special industries such as mining, PVC Junction Boxes are used due to their explosion-proof properties to ensure electrical safety in locations with explosive atmospheres.

Residential Applications

In residential settings, PVC junction boxes are commonly used for electrical connections to lighting fixtures, ceiling fans, power outlets, and switches.

Manufacturing Facilities

In the manufacturing industry, PVC junction boxes require very reliable and well-protected electrical systems to deal with hazards such as flying debris and splashing water.

Medical Facilities

PVC junction boxes in medical facilities need to be highly reliable and easily accessible to protect life safety.

Marine Environments

In marine environments, such as ports, docks, or ships, PVC junction boxes need to be able to withstand waves, wind, corrosive salt water, and even possible submersion.

The variety of designs and sizes of PVC junction boxes allows them to meet different installation needs, while their excellent moisture and weather resistance, as well as cost-effectiveness, make them an indispensable component in modern industrial environments.

Why choose our PVC Junction Box Molds

There are many reasons to choose our PVC Junction Box Molds, here are some key points that highlight the advantages of our products and why customers may benefit from them:

- High-quality materials: Our molds are made of high-quality steel, which ensures the durability and long life of the molds.

- Precision engineering: The mold design is precisely calculated and manufactured to ensure the dimensional accuracy and surface finish of the PVC junction box.

- Customization service: We provide customization services to design and manufacture molds according to the specific needs of customers, including the number of mold cavities and the type of plastic material.

- Advanced manufacturing technology: The latest CNC machining, heat treatment and surface treatment technologies are used to ensure the accuracy and durability of the molds.

- High-efficiency production: Our molds are designed to improve production efficiency and reduce production cycle time, allowing customers to respond quickly to market needs.

- Cost-effectiveness: Compared with similar products, our molds offer a higher cost-effectiveness, helping customers reduce production costs.

- Wide application: Our PVC junction box molds are suitable for a variety of electrical installations, including industrial, commercial and residential uses.

- Technical support: We provide comprehensive technical support and consulting services to help customers solve any technical problems encountered during mold use.

- Fast delivery: We promise to deliver the mold within the agreed time, ensuring that the customer’s production plan will not be affected.

- Continuous innovation: We continuously invest in R&D to improve existing products and develop new technologies to meet the changing needs of the market.

Choosing our PVC Junction Box Molds means choosing reliability, efficiency and professional service, which will bring long-term value to your project.

Testimonials

My Happy Clients!

Purchase process

Below is a brief description of the purchasing process to help potential customers better understand how to buy PVC junction box molds from us:

Step1 : Contact us with your specifications

Customers get in touch with us through the contact information we provide and provide the required specifications and detailed requirements. This may include the size of the mold, design details, material type, expected production volume, etc.

Step2 : Our team will provide a custom quote

Our team will provide a customized quotation based on the specifications and requirements provided by the customer. This quotation will detail the cost of the mold, production time, and any other factors that may affect the final price.

Step3 : Confirm your order and enjoy a seamless production process

After reviewing the quotation and agreeing to all terms, the customer confirms the order. Once the order is confirmed, we will start the production process to ensure that the mold is produced as per the customer’s requirements and schedule.

Step4 : Production Process of Step 3 Continuation

After the order is confirmed, customers can expect a seamless production process. Our team will ensure production efficiency and quality control, regularly updating customers on the production progress.

Step5: Delivery and Follow-up Support

After completing production, we will arrange delivery and ensure that the mold is delivered on time. In addition, we provide ongoing technical support and customer service to help customers solve any installation or production process problems.

Through this process, we ensure that every customer can get the custom PVC junction box mold they need while enjoying a professional and personalized service experience

Contact us to start your cooperation journey

How to contact us

- Free consultation: Contact us now and our team of experts will provide you with a free consultation service to answer all your questions about PVC junction box molds.

- Personalized solutions: Tell us your project needs and challenges, and we will discuss and develop personalized solutions with you.

- Quick response: We promise to respond to your inquiries quickly to ensure that your needs are promptly attended to and handled.

- Flexible cooperation model: Whether you are looking for a one-time purchase or a long-term partnership, we can provide flexible cooperation models to meet your needs.

Take the first step

Take action now

Contact us by phone, email or online form, our customer service team is ready to assist you at any time.

Use our online consultation tool to have a real-time conversation with our sales representative and get instant feedback

Visit our website to browse more detailed information and successful cases about PVC junction box molds.

Seize the opportunity and create a better future

We look forward to working with you to jointly promote your electrical project to success. Don’t hesitate, contact us now and let our plastic PVC junction box mold become the cornerstone of your project success.

Ready to enhance your electrical projects with our Plastic PVC Junction Box Molds? Contact us today to discuss your requirements and get a free consultation.Through this information, we hope to provide customers with a comprehensive window into our products and services and encourage them to take action and connect with us.