Key Concerns in Automotive Interior Mold Production.In the field of automobile manufacturing, the quality and design of interior parts are crucial to the overall impression of the vehicle. In the manufacturing process of interior parts, the quality and design of the mold are also crucial. This article will explore key issues in automotive interior mold production and how to address them to ensure high-quality interior parts manufacturing.

Table of Contents

ToggleKey Concerns in Automotive Interior Mold Production

The mold manufacturing industry has experienced rapid development in recent years, driven by the increased demand for mold replication, which effectively enhances production efficiency and reduces costs. Despite playing a significant role in this fiercely competitive market, mold manufacturing enterprises face substantial competition among themselves. This intensifying competition raises the bar for product quality, leading to an increasing number of factors that require careful consideration during the production process. Today, we will delve into the challenges that mold manufacturers in the automotive industry must address during the production of interior molds.

1. Material selection and durability

The material selection of automotive interior molds directly affects the quality and life of the product. Abrasion resistance, pressure resistance, and high temperature stability are key considerations. Reasonable selection of durable materials can not only increase the service life of the mold, but also reduce production costs and reduce the frequency of mold replacement.

2. Design accuracy and process optimization

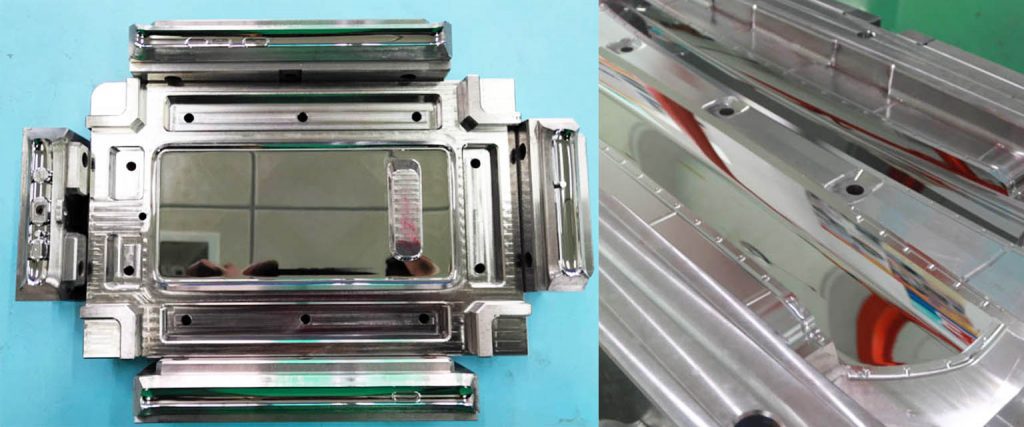

The design accuracy of interior parts plays a decisive role in the appearance and internal layout of the vehicle. In the mold design stage, it is necessary to focus on the optimization of accuracy and process to ensure that the mold can accurately reproduce the design drawings and produce high-quality interior parts.

3. Production efficiency and automation

With the development of the automobile industry, production efficiency and automation have become increasingly important. Optimizing the production process and adopting automation technology can improve the efficiency of mold production, reduce labor costs, and ensure the stability of the production line.

4. Testing and Quality Control

Quality control is an integral part of automotive interior mold production. Establishing an effective inspection system, including strict inspection of molds and finished products, can help identify potential problems and ensure production consistency and quality.

5. Environmental protection and sustainability

In today’s society, environmental protection and sustainability are the focus of the manufacturing industry. Choosing environmentally friendly materials and production processes, as well as optimizing waste treatment processes, can help reduce negative impacts on the environment and are in line with the concept of sustainable development.

6. Innovation and technological upgrading

The continuous pursuit of innovation and technological upgrading is the key to maintaining competitiveness. Paying attention to the latest mold manufacturing technology and design concepts and introducing new technologies in a timely manner will help improve the quality and production efficiency of interior molds.

Time needed for Automotive Interior Mold formation

In the manufacturing process of automotive interior molds, one crucial aspect to consider is the precise duration of product production, as it significantly influences production efficiency. Those familiar with materials are aware that the molding time varies for different materials, leading to considerable differences in the molding time of automotive interior molds. While some molds can be shaped quickly, others may require a more extended period for formation. To enhance production efficiency, it is essential to focus on the specific timing of mold formation.

Temperature needed for Automotive Interior Mold production

The crystallization temperature and speed vary significantly among different materials. While plastics may seem similar to the naked eye, the molding temperature requirements for distinct plastic particles are entirely diverse. Inadequate temperature control poses the risk of mold deformation, leading to size discrepancies. This impact is substantial, emphasizing the crucial importance of comprehending the molding temperature for each type of plastic particle during the production process.

For automotive components and various molds, we extensively employ the CAD/CAE/CAM system in the design, modeling, and programming phases of plastic mold product development. This ensures our capability to produce molds that are high-quality, precise, and well-defined. Our expertise allows us to create molds of excellent quality based on user-provided drawings or samples, offering considerate service with a quick turnaround to meet customer requirements. Additionally, we offer a comprehensive range of services, including mold design, mold development, and injection molding, all within a single business entity.

In the production of automotive interior molds, the solutions to the above key issues will directly affect the quality and market competitiveness of the final product. Therefore, manufacturers need to constantly pay attention and take effective measures to solve these key issues to ensure high-quality manufacturing of automotive interior parts.