Compared with general SMC, the SMC in the SMC laundry tub mold has stricter material requirements, so pay attention to the quality management of raw materials and strictly control the accuracy of the formula. The surface quality of SMC products has an important relationship with the selection of raw materials, such as the use of low-roughness resin, and the resin and fiber are precisely matched.

Table of Contents

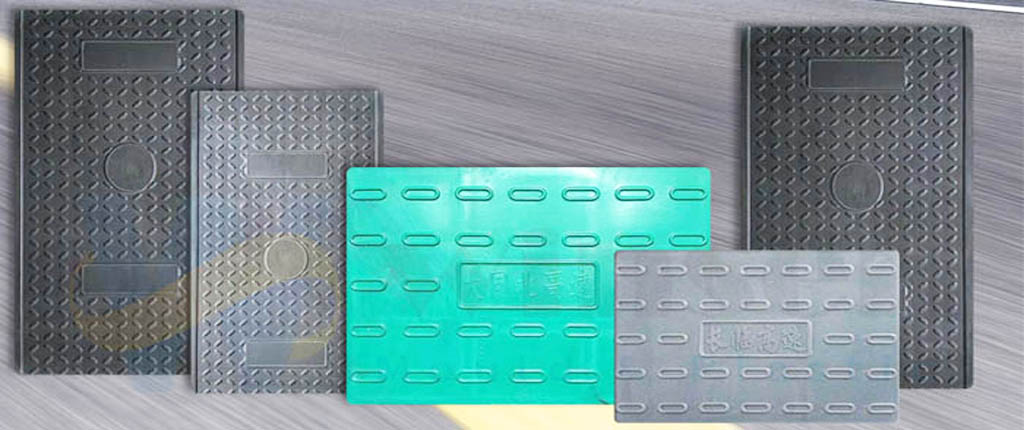

ToggleKey Maintenance Tips for Cable Trench Cover Mould,maintaining the functionality and longevity of cable trench cover moulds is essential for ensuring consistent quality in the production of these vital infrastructure components. In this article, we will explore the key maintenance tips that can help optimize the performance of cable trench cover moulds, enabling smoother manufacturing processes and extending their operational lifespan.

Key Maintenance Tips for Cable Trench Cover Mould

1. Regular Cleaning Routine

Keeping the cable trench cover moulds clean is the foundation of effective maintenance. After each production cycle, thoroughly clean the moulds to remove any residue, debris, or leftover materials. A combination of compressed air, brushes, and mild cleaning solutions can help ensure that the mould surfaces remain free from contaminants that could affect the quality of the finished products.

2. Inspection for Wear and Tear

egular inspections are crucial for identifying any signs of wear and tear. Check the cable trench cover mould surfaces, edges, and cavities for any signs of damage, such as cracks, scratches, or deformations. Early detection of such issues can prevent production defects and reduce the need for extensive repairs later on.

3. Lubrication and Surface Treatment

Proper lubrication of the cable trench cover mould surfaces is vital to facilitate the release of the finished products. Apply a suitable mould release agent to prevent sticking and ensure smooth ejection. Additionally, consider applying surface treatments that enhance the durability and resistance of the moulds against the materials and conditions they come into contact with.

4. Temperature and Humidity Control

Extreme temperatures and humidity levels can impact the performance of cable trench cover moulds. Maintain a controlled production environment to prevent rapid temperature changes that could cause thermal stress. This control will help minimize the risk of warping, cracking, or other deformations in the moulds.

5. Storage and Handling Practices

When not in use, store the cable trench cover moulds in a dry and protected area to prevent exposure to moisture, dust, and other contaminants. Handling the moulds with care, avoiding impacts or rough handling, also contributes to their longevity.

6. Professional Maintenance and Repair

While regular maintenance is crucial, there may come a time when professional maintenance or repair is required. Engage with experts who specialize in mould maintenance and repair to address any significant issues promptly and effectively.

7. Documentation and Tracking

Maintain a comprehensive record of maintenance activities, inspections, repairs, and any modifications made to the moulds. This documentation helps track the history of the moulds and provides valuable insights into their performance and maintenance needs over time.

In conclusion, adhering to a well-structured maintenance regimen is paramount for optimizing the performance and extending the lifespan of cable trench cover moulds. By implementing these key maintenance tips, manufacturers can ensure consistent product quality, minimize downtime, and maximize the return on their mould investment.

What are the precautions for the daily maintenance of the trench cover produced by the cable trench cover mold?

1. When the prepared cover plate is transported to the stacking yard, there will be a double support point between each block. It should be ensured that the double support point is kept in a balanced state, and the electrostatic discharge can be guaranteed for more than eight hours. If If it is summer, you can reduce the release time accordingly. In addition, there is a cover that can retain water.

2. Make sure to water at least 3 times a day, pay attention when watering, and pour up and down along the cover. Especially when the weather is dry, the frequency of watering should be increased, especially in summer and at night. Make sure that the sealing cover is kept wet and can harden in the first time. When the temperature is less than 5 degrees Celsius, it should be covered. When the temperature is below zero, the cable trench cover should be placed indoors as much as possible to prevent cracking.

3. After the cable trench cover is cured, its factory strength should be increased accordingly, and it must exceed 80% of the design strength. Therefore, for the designer, it takes a certain amount of energy and effort. The above are the matters that need to be paid attention to in the maintenance process of the cable trench cover. In addition to these, there are actually many more. No matter what material the cover is, it must be maintained, otherwise, no matter how good the performance is, it will be easy to repair damage. You should not lose the big by the small, or you will regret it too late.