Key point of Injection Mold Maintenance,daily maintenance of injection molds is essential to ensure their longevity and optimal performance. Here are some steps that can be taken to maintain injection molds:

Table of Contents

Toggle1.Clean the mold surface for Injection Mold Maintenance

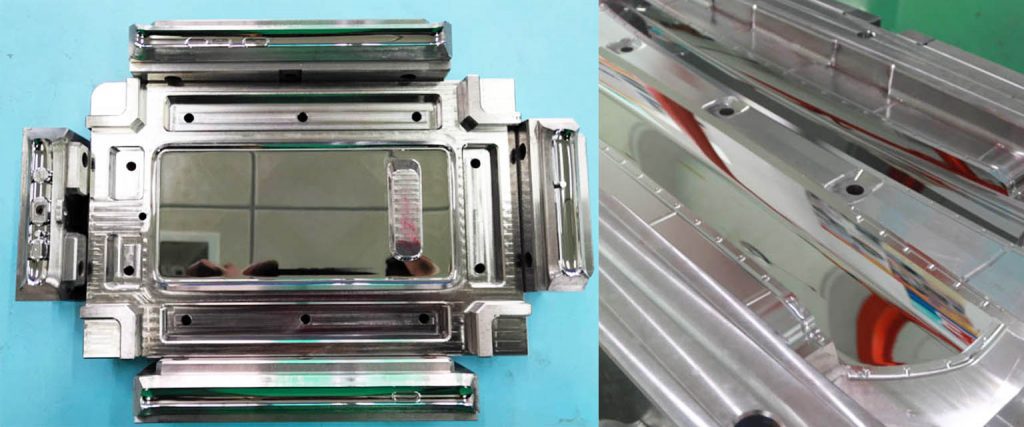

Before starting the production, clean the mold surface with a lint-free cloth or compressed air. Remove any dust or debris that has accumulated on the mold.

2.Lubricate the mold

Apply a thin layer of mold release agent or lubricant to the mold’s surface. This will help prevent sticking or galling of the plastic part.

3.Inspect the mold

Check the mold for any signs of wear or damage, such as cracks, scratches, or deformations. If any problems are found, contact a mold technician to have it repaired.

4.Check the cooling system

Make sure the cooling system is working correctly. Check for any clogged cooling channels or leaks in the water lines.

5.Check the ejection system

Make sure the cooling system is working correctly. Check for any clogged cooling channels or leaks in the water lines.

6.Store the mold properly

When the production is finished, store the mold in a clean, dry location away from sunlight and humidity. Cover the mold with a protective coating or film to prevent rust.

7.Follow the manufacturer's instructions

Always follow the manufacturer’s instructions for maintenance and storage of the mold. They may have specific recommendations based on the type of mold and plastic material being used.

By following these daily maintenance steps, you can help ensure the longevity and optimal performance of your injection mold.

After a production cycle is completed, the molds are generally stored in the warehouse until the next production cycle comes before taking them out for use. If you don’t pay enough attention to the preservation of the mold, the mold will be rusted and the surface finish will decrease during the storage period, resulting in a decline in product quality and a high rejection rate. Some molds are even difficult to reuse. cause great waste. The use and maintenance of the mold account for 15% to 20% of the factors affecting the service life of the mold. The service life of the mold is generally tens of thousands to hundreds of thousands of times according to the structure and shape of the product. If the mold is well maintained, its life will be extended by 2 ~3x is no lie. A pair of well-maintained and maintained molds can shorten mold assembly and debugging time, reduce production failures, make production run smoothly, ensure product quality, reduce waste loss, and reduce the company’s operating costs and mold costs. Investment, the next production cycle At the beginning, the enterprise can successfully produce the products of qualified quality. Therefore, for the processing of die-casting products, in the current fierce market competition, well-maintained molds can help enterprises.

1. After the mold is used for a long time, the cutting edge must be ground

After grinding, the cutting edge surface must be demagnetized, and it must not be magnetic, otherwise it is easy to block the material. Mold users should record in detail, count their use, care (lubrication, cleaning, rust prevention) and damage, so as to find out which parts and components are damaged, so it can provide information for finding and solving problems. As well as the molding process parameters of the mold and the materials used in the product, in order to shorten the test time of the mold and improve the production efficiency.

The properties of mould should be tested under the normal operation of injection molding machine, and final molded plastic part’s size should be measured. Through this information, the existing state of the mold can be determined, and the cavity, core, cooling system and The damage of the parting surface, etc., can be judged according to the information provided by the plastic parts, and the damage status of the mold and the maintenance measures can be judged.

2. Springs and other elastic parts are most easily damaged during use, and usually break and deform

The method to take is to replace. When the replacement is process, it have to pay attention to the specifications and models of springs. The specifications and models of the springs are confirmed by the three items of color, outer diameter and length, and can only be replaced if the three items are the same. The imported spring quality is more better.

3. During the use of the mold, the punch is prone to breakage, bending and gnawing, and the punch sleeve is generally gnawed

In general,damaged punches and sleeves are replaced with parts by same specification. The parameters of punch mainly include working part size, installation part size and length etc.

4. Fasten the parts

Fasten the parts, check whether the fastening parts are loose or damaged, and the method is to find parts of the same specification for replacement.

5. Pressing parts such as pressing plate, excellent glue, etc.

Unloading parts such as stripping plate, pneumatic top material, etc. During maintenance, check the relationship between the parts and whether there is any damage, repair the damaged parts, check whether there is air leakage with the pneumatic jacking material, and take measures for the specific situation. If the air pipe is damaged, please replace it.

It is necessary to focus on tracking and testing of several important parts of the mold: the function of ejection and guide parts is to ensure the opening and closing the mold of movement and the ejection of plastic parts. If any part is stuck due to damage, it will lead to production stoppage, so it should be maintained frequently. Lubrication of the mold thimble and guide post (the most suitable lubricant should be selected), and regularly check whether the thimble and guide post are deformed and surface damaged. Once found, they should be replaced in time;

After completing a production cycle, professional anti-rust oil should be applied to the working surface, motion and guide parts of the mold, and special attention should be paid to the protection of the elastic strength of the bearing parts with gears, rack molds and spring molds to ensure that they are always in the best working condition;

With the continuous production time, the cooling channel is easy to deposit scale, rust, sludge and algae, which makes the cooling channel section smaller and the cooling channel narrower, which greatly reduces the heat exchange rate between the cooling liquid and the mold, and increases the production cost of the enterprise. Therefore, attention should be paid to the cleaning of the flow channel;

For hot runner molds, the maintenance of heating and control systems is particularly important to prevent production failures.