Key points for manufacturing fast food box mould ? When it comes to making fast food box molds, there are some key points that require special attention. These points are crucial to ensure a high-quality and efficient plastic injection foox box mold manufacturing process. In this article, we’ll dive into these points to help you understand the key considerations for manufacturing fast food box molds.

Table of Contents

ToggleKey points for manufacturing fast food box mould

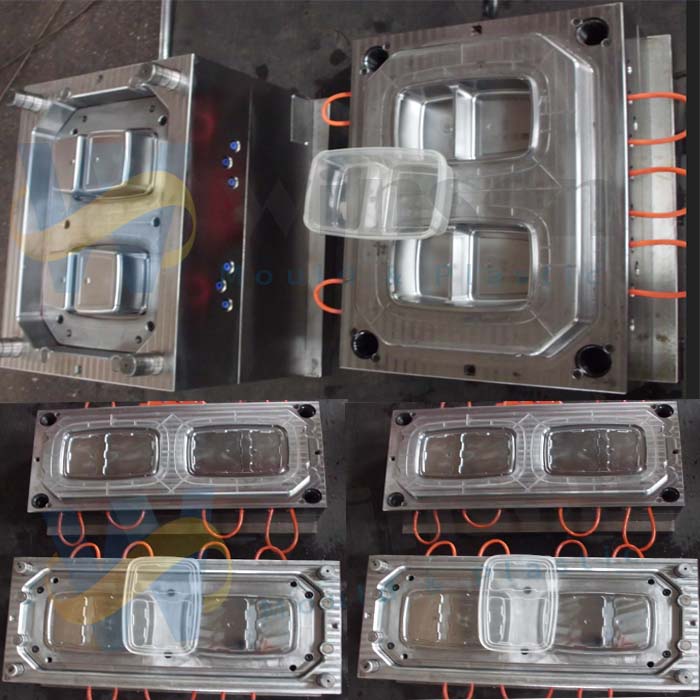

As we advance into the era of increased social connectivity and the reduction of manual labor, the value of our time continues to escalate. The takeaway industry is experiencing rapid growth, resulting in a tremendous surge in the demand for fast-food containers designed for takeout purposes. This surge has given rise to a thriving market for thin-walled molds, including those used for fast-food containers. In this article, we will outline the key inspection criteria for single cavity, two cavity and four cavity food box molds.

1. Food Box Mold Material selection

The first step in making a fast food box mold is choosing the right material. Typically, stainless steel is a common choice due to its excellent corrosion resistance, ease of cleaning, and food safety. Ensure selected materials comply with relevant food safety standards and requirements.

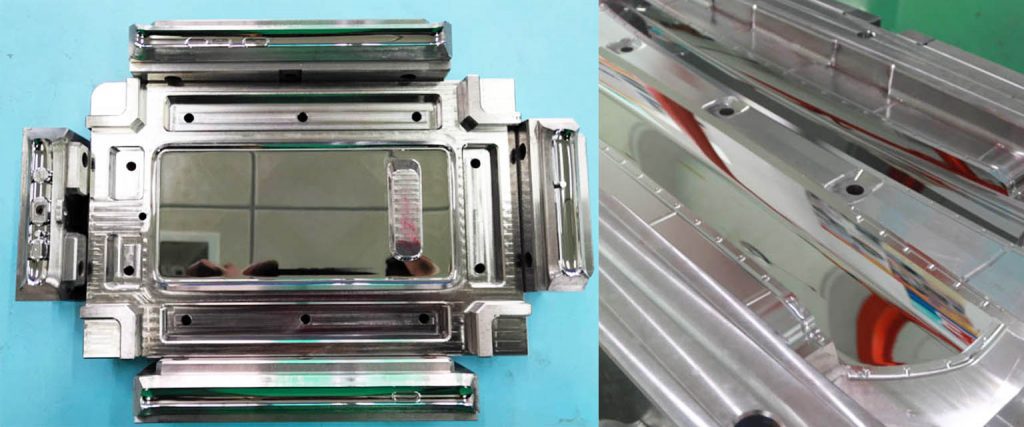

Thin-walled molds, like those used for fast food containers, typically have product wall thicknesses ranging from 0.4mm to 0.8mm. To accommodate such thin walls, high-speed injection molding machines such as Dekumar’s are employed, with injection speeds reaching 350-450mm/s. Due to the necessity of withstanding high pressures, these molds are constructed using high-hardness steel. Materials like Sweden’s 100 Saint’s S136 and Taiwan’s Zhongli’s H13 quenched steel are commonly used, achieving a hardness of HRC42-45 degrees after the quenching process. This choice of steel is essential to prevent mold deformation under the sustained conditions of high speed and pressure, as it ensures the prevention of product flash, ultimately keeping costs in check.

2. Food Box Mold Design accuracy

The design accuracy of the food box mold is crucial. Each part must fit precisely to ensure that the final snack box is consistent in size and shape. Any design deviations can lead to production issues, so ensuring the mold is designed with impeccable accuracy.

The design of thin-walled molds requires careful consideration of several critical factors. These factors include determining the product’s parting surface, designing the appropriate wall thickness for the product, ensuring effective mold exhaust, planning the mold waterway system, and establishing the optimal positions and directions for mold vents. These considerations have a direct and significant impact on the ultimate success or failure of a thin-walled mold

3. Ventilation and cooling system

Integrating effective ventilation and cooling systems into food box molds can help increase production efficiency. Proper ventilation prevents bubbles and deformation within the mold, while cooling systems can reduce production cycles and increase output.

4. Food Box Mold maintenance

Mold maintenance is a key factor in ensuring long-term efficient operation of the food box mold. Regular inspection and maintenance of molds can extend their service life, reduce breakdowns in production, and ensure consistent products are manufactured.

5. Manufacturing process

Manufacturing fast food box molds requires a high degree of machining skills such as milling, drilling and wire cutting. Best manufacturing practices are followed to ensure every step is performed with high precision.

6. Testing and Quality Control

Molds need to undergo rigorous testing and quality control before being put into use. This includes integrity testing and performance testing to ensure the food box mold meets requirements, resulting in a high-quality product.

7. Customer needs

Most importantly, make sure you work closely with your customers to understand their specific needs. Fast food box molds should be designed and manufactured as per the customer’s specifications and requirements to meet their expectations.

8. Full Automation is Essential for Food Box Mold Production

Thin-walled products represent a sector characterized by slim profit margins but rapid turnover. Integrating a manipulator into the process can significantly enhance production efficiency. The manipulator aids in direct stacking, while conveyor belts facilitate seamless packaging and swift shipment

Choose the appropriate foox box size and shape

Currently, available options in the market for fast food boxes include both round and rectangular shapes. The standard capacities typically range from 500ml, 750ml, to 1000ml. It’s worth noting that round-shaped containers tend to be slightly lighter in weight compared to their square counterparts

To sum up, manufacturing fast food box molds requires precision craftsmanship and expertise. Following these points can ensure the high quality, reliability and durability of the mold, improve production efficiency and meet customer needs. Whether you are a professional in making molds or someone interested in this field, these points will be helpful to you.