Revolutionizing Plastic Packaging: Plastic Injection 80L Bucket Molds for Venezuela

Discover how we bring premium plastic injection bucket mold technology to Venezuela to meet the unique needs of the local market.

In today’s globalized world, the demand for plastic bucket molds continues to grow, especially in regions that seek efficient and environmentally friendly packaging solutions. Venezuela, with its rich natural resources and growing industrial market, has an urgent need for high-quality plastic bucket molds. This article will share how we brought advanced injection bucket mold technology to Venezuela, as well as the challenges and opportunities in the process.

Table of Contents

ToggleThe Introduction of Plastic Injection Bucket Molds to Venezuela

Importance of injection bucket molds

In the plastic products industry, molds are the key to producing high-quality plastic buckets. A good mold not only ensures product consistency and precision, but also improves production efficiency and reduces costs. We focus on designing and manufacturing injection bucket molds that can meet different market needs.

Demand analysis of the Venezuelan market

The demand for plastic buckets in the Venezuelan market is mainly concentrated in the fields of packaging, storage and transportation. We conducted an in-depth analysis of the local market and understood the specific needs of customers, including the size, shape, chemical resistance and durability of the buckets.

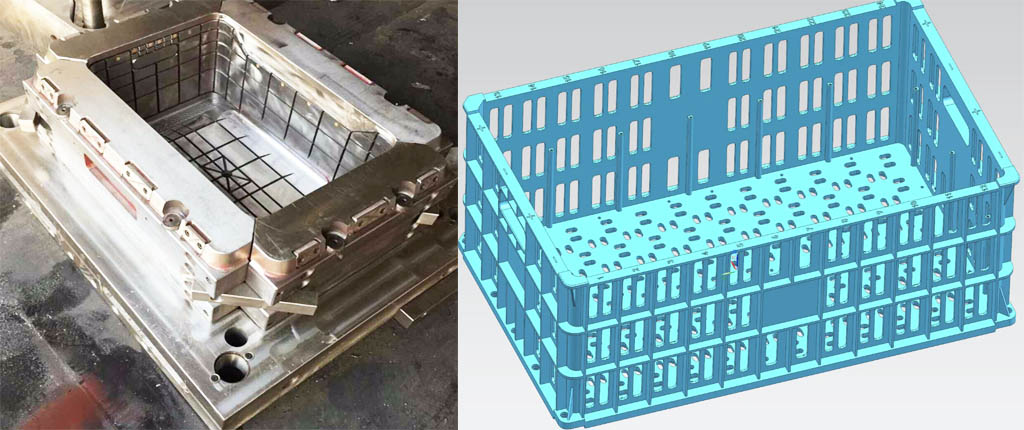

Customized plastic injection bucket molds design

Based on market analysis, we provide customers with customized plastic bucket mold design solutions. Our team of designers and engineers work closely to ensure that each injection bucket mold meets specific functional and aesthetic requirements.

Material selection and technological innovation

In terms of material selection, we use high-performance steel and advanced surface treatment technology to improve the durability and corrosion resistance of the bucket mold. At the same time, we are constantly exploring new manufacturing technologies, such as 3D printing, to shorten the plastic injection barrel mold development cycle.

Challenges and opportunities of cross-cultural cooperation

The cooperation with Venezuelan customers has made us deeply realize the importance of cross-cultural communication. We overcame language and cultural differences by establishing effective communication channels to ensure the smooth progress of the plastic injection pail molds project.

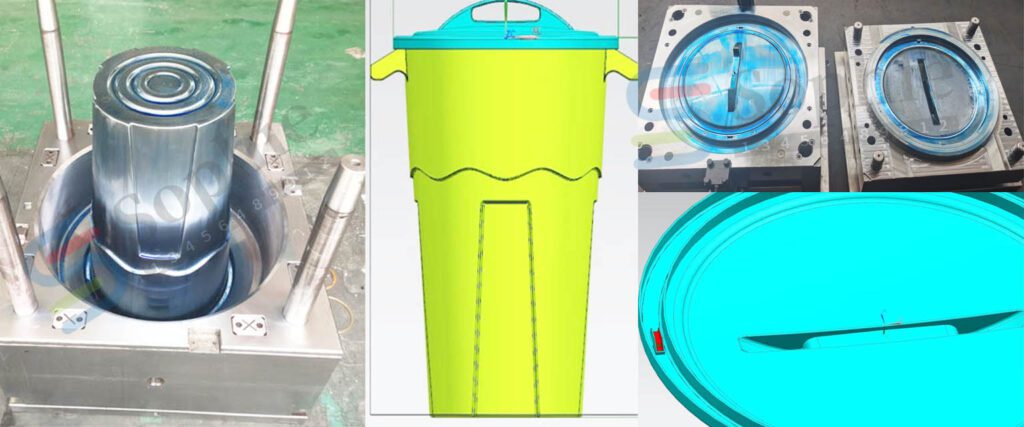

Plastic injection bucket molds details

The details of the bucket mold we designed and made are as follows:

- Capacity:80L

- P20 steel

- 1 cavity

- Hot runner

- Mold size: 860*860*940MM

- Mold weight: 5240KG

- Cycle time:35-40s

Plastic injection bucket lid molds details

The details of the plastic bucket lid mold we designed and made are as follows:

- P20 steel

- 1 cavity

- Hot runner

- Mold size: 910*800*480MM

- Mold weight: 1480KG

- Cycle time:25-30s

Project Implementation and Customer Feedback

During the plastic barrel mold manufacturing process, we pay attention to every detail to ensure that the injection barrel mold quality meets the highest standards. After the project was completed, we received positive feedback from customers, who expressed high satisfaction with our products and services.

Continuous Service and Support

We not only provide one-time plastic injection bucket mould manufacturing services, but also provide customers with continuous technical support and after-sales service. We believe that this long-term partnership is the key to business success.

Continuous Service and Support

We not only provide one-time plastic injection bucket mould manufacturing services, but also provide customers with continuous technical support and after-sales service. We believe that this long-term partnership is the key to business success.

Summary and Outlook

Through this cooperation with Venezuela, we not only consolidate our professional position in the plastic bucket mould industry, but also demonstrate our ability to cooperate across cultures. Looking to the future, we will continue to expand the international market and provide high-quality injection bucket mold solutions to global customers.

Although the competition in the plastic bucket mold industry is fierce, we are confident that we can maintain our leading position in the market through continuous technological innovation, customized services and cross-cultural cooperation. We look forward to working with partners from more countries to create more value.