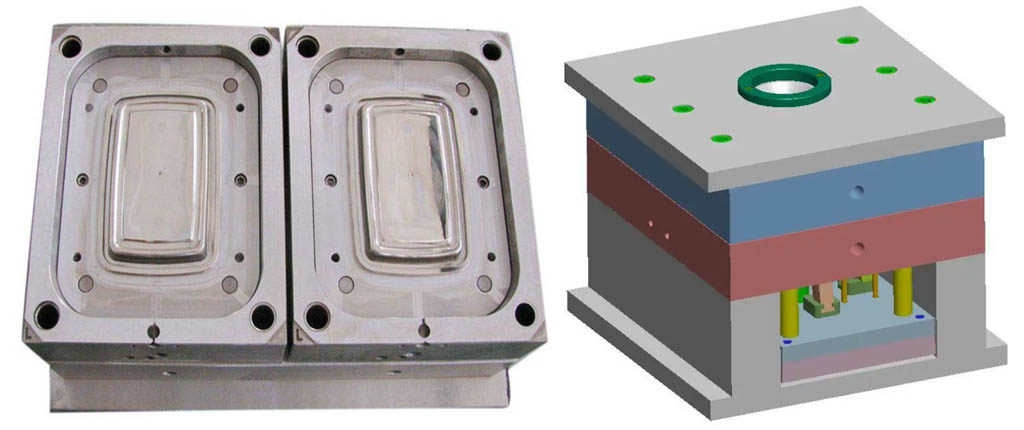

Plastic Injection crate box mold manufacturer,Taizhou WS Mold Factory is a well-established company with extensive expertise in the design and production of storage box molds, logistics box molds, sorting box molds, turnover basket molds, and turnover box molds of various specifications. Their years of experience and specialization make them a trusted name in the industry.

Table of Contents

TogglePlastic Injection crate box mold manufacturer

In today’s world, plastic injection mold manufacturers play a vital role, especially in the packaging industry. Among them, manufacturers of plastic injection crate box molds have a profound impact on the design and manufacturing of boxes used to store, transport and protect goods in daily life. In this article, we take a closer look at the critical role of plastic injection mold manufacturers and how they are shaping the future of packaging

1. Innovative design

Plastic injection crate box mold manufacturers are not just factories that make boxes, they are also innovative designers. They develop new plastic crate box molds to adapt to different types of goods, improve storage and transportation efficiency, and ensure that goods are safe and intact throughout the supply chain. This includes considering the strength, weight, size, stackability and other factors of the crate box mold to meet the diverse needs of customers.

2. Improve sustainability

As sustainability issues become increasingly important, plastic injection crate box mold manufacturers are also promoting environmental protection and sustainable development. They are committed to developing crate box molds made of recyclable materials to reduce waste and improve the effective use of resources, thereby reducing environmental impact.

3. Customized solutions

Every industry and every customer has unique needs. Plastic injection crate box mold manufacturers are able to provide customized solutions, designing and manufacturing crate box molds according to customer requirements. This customized nature makes them a valuable partner to a variety of industries, serving the needs of diverse industries, from food and healthcare to electronics and agriculture.

4. Improve production efficiency

The use of injection crate box molds helps improve production efficiency. They make the production of crate boxes faster and more precise, reducing manual work, lowering production costs and increasing production capacity.

5. Adapt to the needs of various industries

Plastic injection crate box mold manufacturers serve a variety of industries including agriculture, healthcare, retail, and industrial. Their versatile crate box molds can adapt to the needs of different industries, providing boxes suitable for a variety of uses.

6. Improve product protection

Packaging crate boxes are essential for the protection of goods, especially during transportation and storage. Design and technology improvements by plastic injection box crate mold manufacturers help improve product protection levels. They can integrate various special functions, such as shockproof, moisture-proof, temperature control, etc., to ensure that all types of goods are not damaged during long-distance transportation.

Crate turnover box molds are essential for mass-producing turnover boxes

Turnover boxes find extensive applications in various industries, including machinery, automotive, home appliances, light industry, electronics, and more. They boast qualities such as resistance to acid, alkali, and oil, are non-toxic, and odorless, making them suitable for storing even food items. With their well-thought-out design and high-quality construction, they are a valuable asset for the transportation, distribution, storage, and processing in factory logistics. These versatile turnover boxes can be seamlessly combined with different logistics containers and workplace equipment, making them indispensable in warehouses, production facilities, and beyond.

In today’s business landscape, logistics management is of increasing importance. Turnover boxes play a crucial role in standardizing logistics containers, supporting integrated management, and facilitating modern logistics management for production and distribution enterprises.

For those interested in exploring the market potential of turnover boxes, we encourage you to inquire about the latest developments in turnover box molds.

Turnover basket molds enable the fast production of turnover baskets

Turnover baskets, often referred to as plastic baskets due to their predominant plastic composition, serve as integral components in industrial assembly lines, circulation, and storage. They are commonly regarded as part of the “industrial three treasures,” alongside turnover boxes and pallet boxes. In recent times, turnover baskets have found application in the agricultural sector, replacing traditional bamboo baskets for fruits and vegetables.

These baskets come in various types, including mesh stackable, mesh coverable, and closed coverable, catering to different needs in warehouses, production lines, and internal factory operations. While stackable types are suitable for stacking, the collapsible types save space when not in use. Mesh baskets are ideal for stacking solid items, whereas the closed types can accommodate both solid and liquid items. Some are designed as disposable plastic crates. Turnover baskets can also be categorized as general or anti-static based on their performance.

Key attributes of turnover baskets include cost-effectiveness, environmental friendliness, hygiene, safety, and convenience. They are economical, recyclable, environmentally friendly, and capable of withstanding acid and alkali, preventing mold, moisture, and pests. Moreover, they are safe, with no nails, radiation, toxicity, or odor, and are easy to handle with minimal maintenance requirements. As the global economy evolves and the agricultural industry advances in the new era, turnover baskets are poised to play an increasingly vital role in the economy.

All in all, plastic injection box mold manufacturers do much more than just make boxes. They are innovators in the packaging industry, providing highly customized solutions that drive improvements in production efficiency while also making significant strides in the areas of sustainability and environmental protection. No matter your industry or needs, these manufacturers will continue to shape the packaging industry of the future.

No matter which industry you are in, plastic injection box mold manufacturers are your potential partners and will provide you with high-quality customized packaging solutions.