Plastic injection mold for automotive battery box to Mexico,plastic injection molding for automotive battery box components: Powering the Mexican automotive industry

Table of Contents

ToggleWith the rapid development of the global automobile industry, automobile manufacturers have an increasing demand for high quality, high performance parts. As an indispensable part of modern manufacturing, plastic injection molding technology is providing efficient and economical solutions for the production of automotive parts. Among them, the demand for automotive battery box component molds is particularly significant. Our company recently successfully sent a batch of precision plastic injection batter box parts molds to Mexico to help the development of the local automobile industry.

The Rise of the Mexican Auto Industry

As one of the world’s important automobile manufacturing centers, Mexico has achieved remarkable results in automobile production and export in recent years. Key advantages include:

Strategic location

Mexico’s close proximity to the United States, the world’s largest automotive market, makes it an ideal production base for many automakers.

Preferential policies

The Mexican government has provided a series of preferential policies and investment environment for the automobile industry, attracting a large number of international automobile companies to settle in.

Labor advantage

Mexico has a large number of well-trained labor resources, providing a solid manpower foundation for automobile manufacturing.

The Importance of Modern Plastic Injection Molding Technology

inject plastic raw materials into the mold and obtain the required parts after cooling and molding. Compared with traditional manufacturing methods, plastic injection molding has the following advantages:

Efficient production

Injection molding technology can produce a large number of parts in a short time to meet the needs of mass production.

Cost savings

Since the mold can be reused, the production cost of a single product is greatly reduced.

High precision

Modern injection molding technology can produce parts with extremely high precision, meeting the automotive industry’s demand for high-precision parts.

Material diversity

Injection molding technology can use a variety of plastic materials, and the most suitable material can be selected according to different needs.

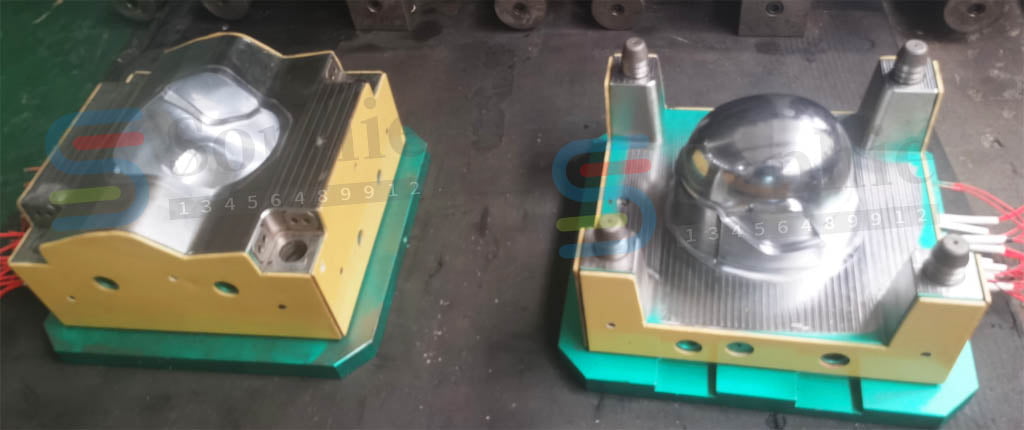

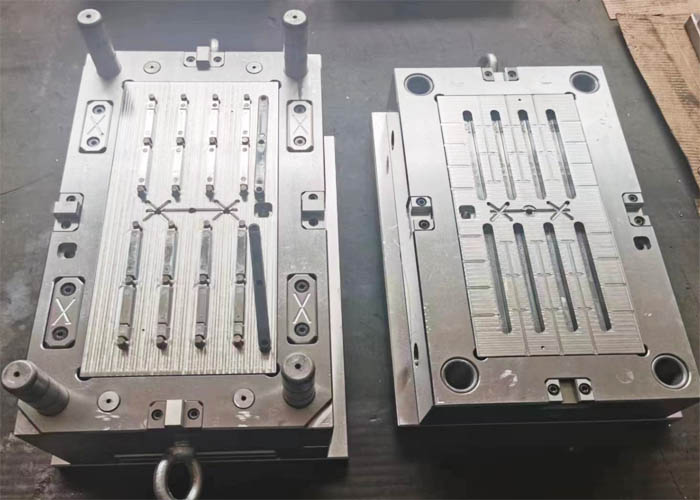

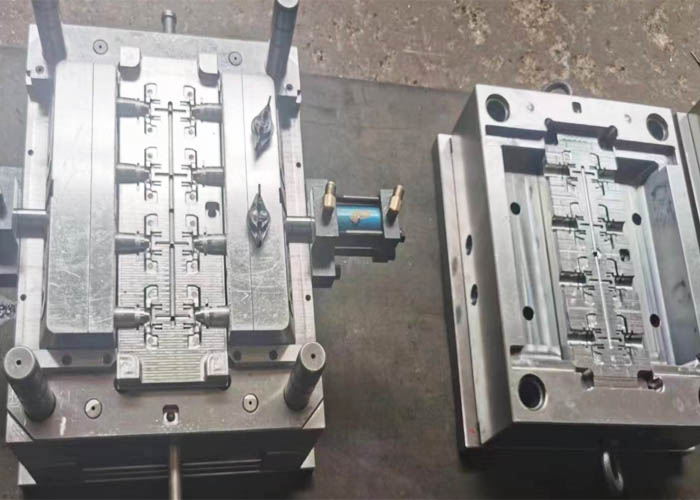

Our plastic injection molds: quality meets innovation

The plastic injection car battery box parts mold sent to Mexico this time is the result of our company’s years of technology accumulation and innovation. We strictly follow the following principles during the mold design and manufacturing process:

High-quality materials

Use high-strength, wear-resistant mold steel to ensure long life and stable performance of the mold.

Precision manufacturing

Using advanced CNC processing technology and precision testing equipment to ensure the dimensional accuracy and quality consistency of each set of molds.

Customer customization

Personalized design according to customer needs to meet the requirements of different models and battery box specifications.

Environmentally friendly production

Pay attention to environmental protection during the production process, adopt low-energy consumption and low-emission manufacturing processes, and comply with international environmental protection standards.

With the successful shipment of this mold, we look forward to establishing closer cooperative relationships with Mexican automobile manufacturers to jointly promote the development of the global automobile industry. We will continue to uphold the principles of quality first and customer first, continue to innovate, provide better products and services, and contribute to the sustainable development of the global automotive industry.

In the future, we will continue to be committed to technological progress and product optimization, meet market challenges, seize development opportunities, and contribute to the prosperity of the global automobile manufacturing industry.