Learn from Plastic Injection Molds

Industry Experts

Precision plastic injection molds & Parts manufacturing, One-stop on-demand manufacturing service

Fast Cycle Time

Excellent cooling system design shortens the molding cycle time

Long Mold life

Selected mold steel escorts the life of the mold

Fast Delivery

Perfect management and equipment guarantee fast delivery within 15-30 days

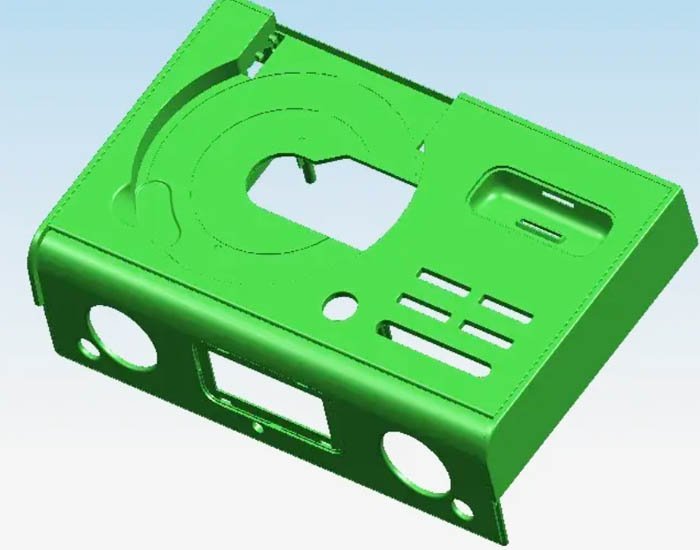

What Is Plastic Injection Molds

Plastic injection mold is the main tool for molding plastic products. It can produce plastic products with the same shape and size more quickly and quickly. For many products, injection molds are an important tool for them to produce various plastic products.

Plastic products produced by injection molds have the advantages of light weight, high strength, good toughness, corrosion resistance, good insulation, easy coloring, easy molding, and low cost, so they are favored by all walks of life.

Injection molds can easily and quickly provide plastic products with complete structures and precise dimensions.

Main types of plastic injection molds

1. Rubber injection molding: Rubber injection molding is a production method in which the rubber material is directly injected into the model from the barrel for vulcanization. The advantages of rubber injection molding are: although it is an intermittent operation, the molding cycle is short, the production efficiency is high, the blank preparation process is cancelled, the labor intensity is small, and the product quality is excellent.

2. Plastic injection molding: Plastic injection molding is a method of plastic products. The molten plastic is injected into the mold of plastic products by pressure, and the desired plastic parts are obtained by cooling and molding. There are mechanical injection molding machines dedicated to performing injection molding. The most commonly used plastics are polyethylene, polypropylene, ABS, PA, polystyrene, etc.

3. Molding and injection molding: The resulting shape is often the final product, and no other processing is required before installation or use as a final product. Many details, such as bosses, ribs, and threads, can be formed in a single injection molding operation.

Below we mainly introduce plastic injection molds

Plastic injection mold is a special tool used for the production of plastic products. The heated and molten plastic material is injected into the mold cavity through an injection molding machine. After cooling and molding, plastic products of the required shape and size are obtained. Injection molds are usually made of mold steel, which has high strength and wear resistance to ensure long-term use under high pressure and high temperature conditions. It is widely used in many fields, including automobile parts, electronic product casings, home appliances, medical equipment, etc.

Plastic mold is a tool that is matched with plastic molding machines in the plastic processing industry to give plastic products a complete configuration and precise size. According to the different molding methods, it can be divided into different types of molds

1. Injection Molds

It is mainly a molding mold that is most commonly used in the production of thermoplastic parts. The processing equipment corresponding to the injection mold is an injection molding machine. Under the push of the plug, it enters the mold cavity through the injection molding machine nozzle and the pouring system of the mold, and the plastic is cooled and hardened to form, and the product is obtained by demolding.

Its structure is usually composed of forming parts, pouring system, guiding parts, push-out mechanism, temperature regulation system, exhaust system, supporting parts, etc., and is made of plastic mold steel. The injection molding processing method is usually only suitable for the production of thermoplastic products. The plastic products produced by the injection molding process are very extensive. From daily necessities to various complex electrical appliances and auto parts, they are all formed with injection molds. One of the most widely used processing methods in the production of plastic products.

2. Blowing Molds

A mold used to form plastic container hollow products (such as beverage bottles, daily chemical products and other packaging containers). The form of blow molding mainly includes extrusion blow molding and injection molding according to the process principle. The principle mainly includes extrusion blow molding, injection blow molding, injection extension blow molding (commonly known as injection stretch blow), multi-layer blow molding, sheet blow molding, etc. The equipment corresponding to blow molding of hollow products is usually called plastic blow molding machine, and blow molding is only suitable for the production of thermoplastic products. The structure of the blow mold is relatively simple, and the materials used are mostly made of carbon.

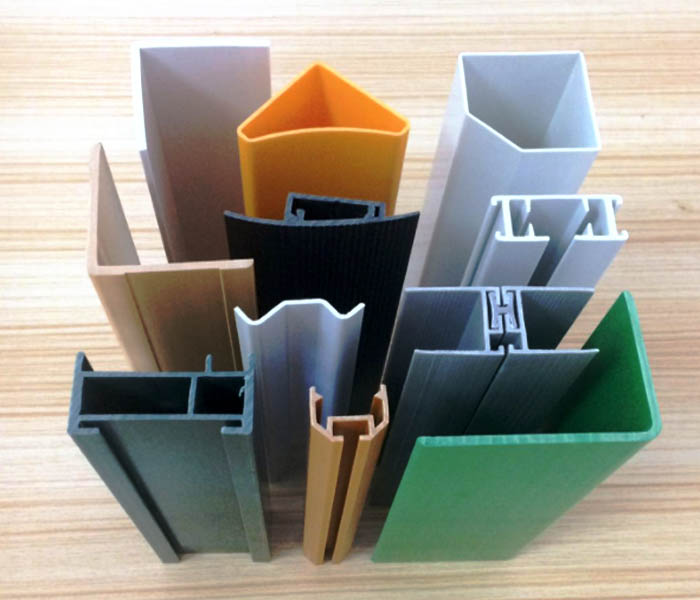

3. Extrusion Molds

A type of mold used to produce continuous-shaped plastic products, also known as extrusion molding head, is widely used in the processing of pipes, bars, monofilaments, plates, films, wire and cable cladding etc.

The corresponding production equipment is a plastic extruder, the principle of which is that the solid plastic is melted and plasticized under the conditions of heating and the screw rotation of the extruder, and is made into the same cross-section as the shape of the die through a die of a specific shape. Continuous plastic products. Its manufacturing materials are mainly carbon structural steel, alloy tools, etc., and some extrusion dies are also inlaid with wear-resistant materials such as diamond on the parts that need to be wear-resistant.

The extrusion process is usually only suitable for the production of thermoplastic products, which is significantly different from injection molds and compression molds in structure.

4. Blister Molds

A mold that uses plastic plates and sheets as raw materials to form some simpler plastic products. In the case of softening, it is deformed and attached to the cavity of the mold to obtain the desired molded product, which is mainly used in the production of some daily necessities, food and toy packaging products.

Due to the low pressure during molding, the mold material is mostly made of cast aluminum or non-metallic materials, and the structure is relatively simple.

5. Compression Mold

Including compression molding and injection molding two structural mold types. They are a type of mold mainly used to mold thermosetting plastics, and their corresponding equipment is a press molding machine.

Compression molding method According to the characteristics of plastic, the mold is heated to the molding temperature (generally 103°108°), then the measured compression molding powder is put into the mold cavity and the feeding chamber, the mold is closed, and the plastic is heated under high heat and high pressure. Soften the viscous flow, solidify and shape after a certain period of time, and become the desired product shape.

The difference between injection molding and compression molding is that there is no separate feeding chamber. The mold is closed before molding, and the plastic is preheated in the feeding chamber and becomes a viscous flow state. Under the action of pressure, it is adjusted and squeezed into the mold cavity to harden and form.

The compression mold is mainly composed of cavity, feeding cavity, guiding mechanism, ejecting parts, heating system etc. Injection molds are widely used in packaging electrical components. The materials used in the manufacture of compression molds are basically same as injection molds.

6. High expanded polystyrene molding molds

It is a kind of mold that uses expandable polystyrene (bead material composed of polystyrene and foaming agent) raw materials to form foam packaging materials of various desired shapes.

The principle is that expandable polystyrene can be steamed in the mold, including two types of simple manual operation molds and hydraulic straight-through foam plastic molds, which are mainly used to produce packaging products for industrial products. The materials for making such molds are cast aluminum, stainless steel, bronze, etc.

The mold manufacturing process is a complex process, from the steps of design, processing, assembly, debugging, etc., and finally it can be put into use. In the whole life cycle, the factors affecting the quality of mold mainly include the following ten aspects:

Factors Affecting Mold Quality

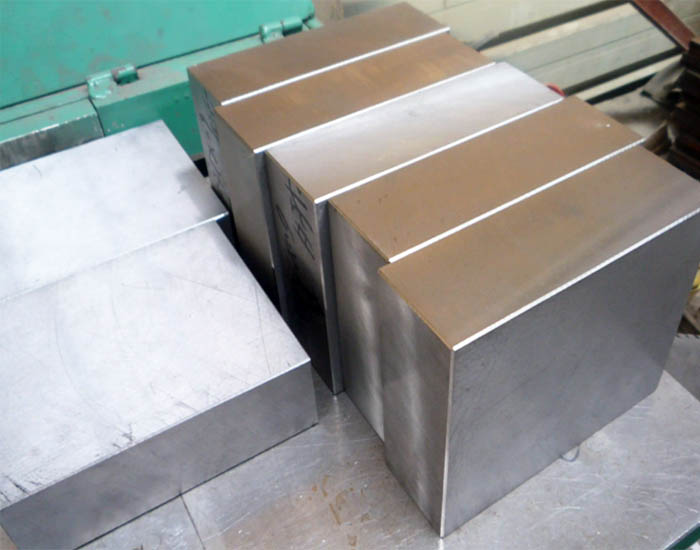

1. Molds Steel

Steel is the decisive factor for the quality of the mold, and choosing a reasonable steel is the top priority. The criteria for selecting steel are:

1). Requirements for injection molding materials: Different plastics should use different steels, such as high polishing requirements, corrosion resistance requirements, etc.;

2). Price: It is good that the steel can be used, not the more expensive the better; considering the cost factor of the mold, the mold steel should choose the material corresponding to the life of the mold to avoid unnecessary waste; generally, the life of P20 is about 300,000; 2738, 500,000 is no problem, H13/2344 is usually above 800,000-1 million, you can choose according to the situation;

3). Heat treatment: The surface treatment of the mold is also very important. Nitriding – can enhance the surface hardness of steel and effectively prolong the life of the mold; electroplating – can effectively modify the mold steel, and for some plastic parts that require high brightness and corrosion resistance, electroplating can be used to enhance and improve the performance of the steel.

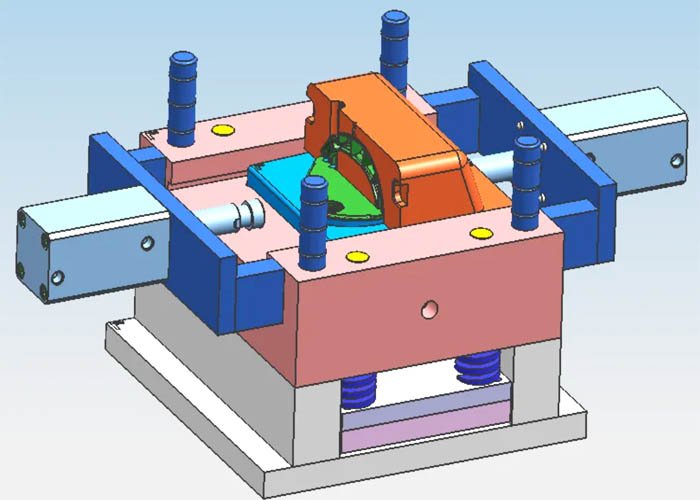

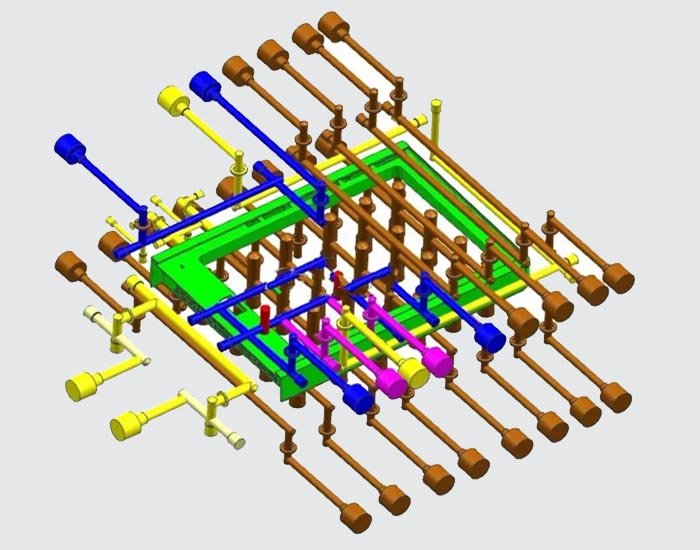

2. Structural design

The mature mold structure not only takes into account the material properties of the product – shrinkage rate, molding temperature, elastic tensile deformation coefficient, etc., but also takes into account the cooling water path, the speed of opening and closing the mold, etc. Reasonable mold structure can effectively prolong the life of the mold and ensure the smooth production of the mold. Improve efficiency and reduce costs.

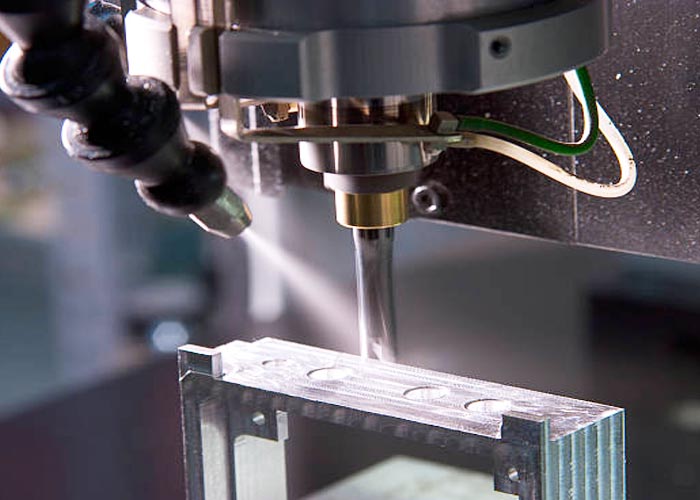

3. Mold processing

If a worker wants to do a good job, he must first sharpen his tools. The arrangement of the mold process is particularly important. A reasonable process arrangement can speed up the production cycle, shorten the processing time, and effectively save costs. And more importantly, accurate and reasonable processing can ensure the stability and prolong the life of the mold in the production process.

Some machining errors will lead to mold welding, no matter how good the welding is, it is a loss to the mold; poor processing may also affect the mold action, reduce the life of the mold, and cause the mold to crack or even in the production process. break.

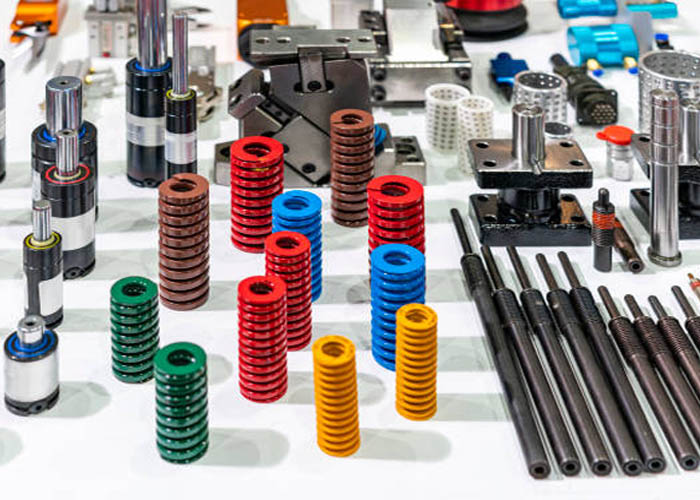

4. Standard parts

It is the lowest piece of wood that determines the capacity of the bucket. But it’s often not noticed when doing it. The same is true for the mold. Although the standard part does not directly participate in the molding, it controls the operation of the entire mold.

Good standard parts should be able to wear-resistant, hard enough, high precision, not easy to deform. The price difference of standard parts of different brands is very large. Do not blindly pursue the lowest price when making molds.

5. Touch (flying mold)

It relies on the experience of the mold fitter, and the seemingly simple work is the most technical work. The complex mold mainly depends on this skill. The flat mold is the simplest, and the fractal surface is basically ok as long as there is no flash break. For example, auto parts molds are very troublesome, not only the fractal surface is relatively irregular, but also often includes multiple sliders and top blocks. Other problems of the mold can also be improved and perfected by bumping. It is a comprehensive work.

6. Polished/Skin texture

The polishing of the mold is the last link of mold making. Polishing is directly reflected on the plastic parts, which is a face job. Polishing can also help and supplement the mold action, especially for demolding. Often, some molds are not produced smoothly because the lighting is not in place, the resistance is too large, the mold release is difficult, and even the top is white and the top is cracked.

7. Mold assembly

Mold assembly is like assembling a machine. Every part and every screw can’t go wrong. Otherwise, it will lead to product defects and affect production, and in severe cases, it will completely damage the mold and cause scrap. Assembly must be very meticulous. During the assembly process, special attention should be paid to the cleaning of the mold, especially the waterway and screw holes, and the iron filings inside must be blown clean.

8. Hot runner or cold runner

In fact, this has the least impact on the quality of the mold, because the hot runners are generally designated by customers, especially some large customers. Well-known brands have done very well in terms of quality and after-sales service, so there is generally no problem in quality. It’s just that some small businesses strive for price advantages in order to save costs and use some unreliable heating and conduction accessories, which are prone to problems. The main problem of cold runner is how to ensure the balance of injection molding, gate size, injection pressure and so on.

9. Cooling System

Cooling is important for a mold. Due to the increase in prices and labor wages, when mass-producing products, the profit brought by every second of the injection cycle time is considerable.

Speeding up the production cycle will increase the temperature of the mold. If it is not effectively controlled, the mold will be too hot to be formed, and even lead to the deformation of the mold and the failure to be scrapped. Therefore, good waterway design is particularly important, including the arrangement density, diameter, and links between waterways and so on.

10. Mold Maintenance

Mold maintenance is mainly maintenance and maintenance in the production process. The mold is like a car. If it is not used for a long time without maintenance, the mold may be scrapped. Every time the mold is used, a comprehensive maintenance should be carried out, especially the rust prevention of molding part and the rust prevention of the main moving parts.

Because the mold needs to receive water during the production process, there may be water on the mold during the installation or disassembly process, so it is necessary to ensure that the mold is dry, and then apply a layer of oil to protect it.