Among the many technologies in the manufacturing industry, rubber compression molding stands out for its unique advantages and wide applications. This technology transforms unvulcanized rubber into products with specific shapes and functions through high temperature and high pressure, and has become an indispensable part of modern industry. With the advancement of science and technology and the growth of market demand, rubber compression molding technology is ushering in new development opportunities.

Table of Contents

ToggleAnalysis of Rubber Molding Technology

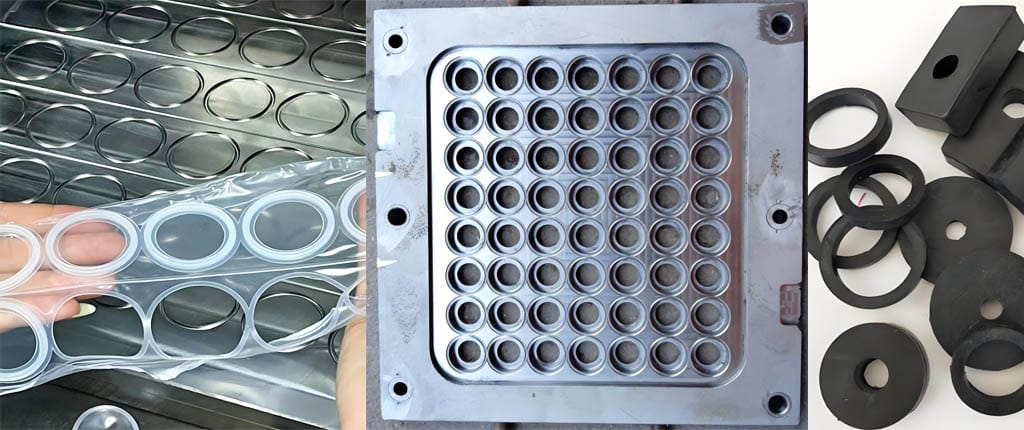

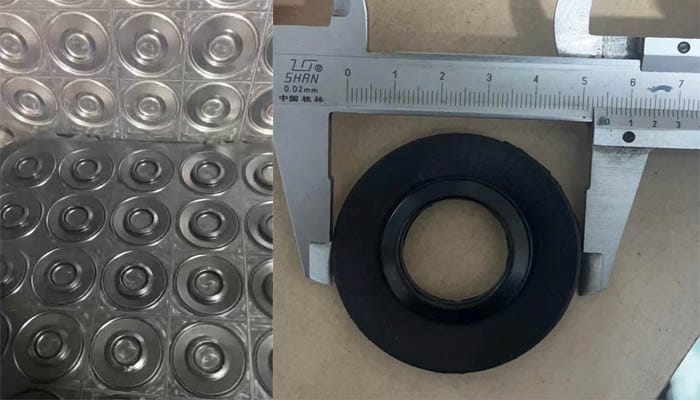

Rubber compression molding is a closed mold high pressure molding process, which involves placing uncured rubber raw materials or preforms in a heated mold, filling the mold with pressure and vulcanizing the mold. This method is suitable for raw materials such as silicone and rubber, and can accurately replicate the shape and details of the mold under specified time and temperature conditions. This process is extremely efficient and cost-effective for manufacturing various rubber products such as seals, gaskets, shock absorbers, etc.

Rubber Compression Molding Applications

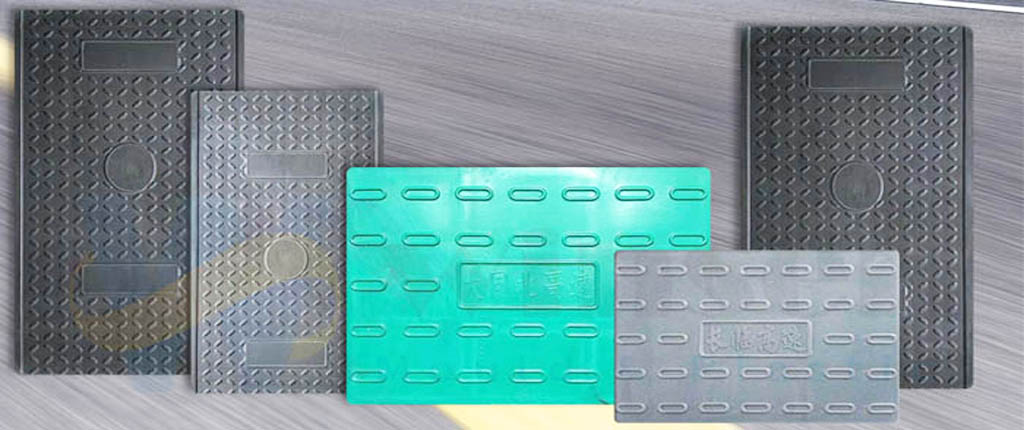

Rubber compression molding technology is widely used in the manufacture of automotive tires, seals, O-rings, gaskets, valves, diaphragms and other parts due to its high cost-effectiveness and low material waste. It is particularly suitable for materials that require a long curing time, as well as lamination molding of rubber and metal substrates. In addition, rubber compression molding technology is also used in medical devices, electronics, aerospace and other fields. Its wide range of applications reflects the importance and flexibility of this technology.

Rubber compression molding market trends

The global rubber compression molding machine market is experiencing steady growth. According to YH Research, the market size is expected to be close to RMB 100 million by 2030, with a compound annual growth rate (CAGR) of RMB 100 million in the next six years. This growth is due to population growth and the development of the automotive industry in the Asia-Pacific region, especially in China, where the market size is expected to continue to expand. As the global demand for high-performance rubber products increases, rubber compression molding technology will continue to play an important role in the manufacturing industry.

Progress in Rubber Compression Molding Technology

With the introduction of new materials and technologies, rubber compression molding technology is also constantly improving. For example, the development of new rubber pressure molding technology (RPM) makes it possible to process long fiber/fabric reinforced polymer composites with complex geometries. In addition, the research on the mechanical properties of rubber molded samples is also deepening, comparing the effects of two basic production technologies, compression molding and injection molding, on product performance. These studies not only improve the performance of rubber products, but also open up new possibilities for the application of rubber compression molding technology.

Environmental impact of rubber compression molding

The environmental impact of rubber compression molding technology is also the focus of the industry. With the global emphasis on sustainable development and environmental protection, rubber compression molding technology is moving towards a more environmentally friendly and energy-saving direction. For example, by optimizing process parameters, reducing energy consumption and waste generation, rubber compression molding technology is working to reduce its impact on the environment.

Challenges in the Rubber Compression Molding Industry

Although rubber compression molding technology has many advantages, it also faces some challenges. Fluctuations in raw material prices, the speed of technological upgrading, and the intensification of global market competition are all issues that the industry needs to face. In addition, as consumers’ requirements for product quality increase, rubber compression molding technology also needs to continuously improve its precision and efficiency to meet market demand.

Future Outlook for Rubber Compression Molding

Looking ahead, rubber compression molding technology will continue to develop driven by new materials, new processes and new technologies. The application of automation and intelligent technology will further optimize the production process and improve production efficiency. At the same time, with the global attention to sustainability, rubber compression molding technology will also pay more attention to environmental protection and energy saving. It is expected that in the next few years, rubber compression molding technology will be applied in more fields, such as new energy, biomedicine, etc., and its market prospects are broad.

Rubber compression molding technology plays an important role in modern industry with its unique advantages. With the continuous advancement of technology and the growth of market demand, this field will continue to show great potential and development prospects. By deeply understanding this technology, we can better grasp the industry dynamics and seize development opportunities. With the continuous development of the global manufacturing industry, rubber compression molding technology will surely play a more important role in the future.