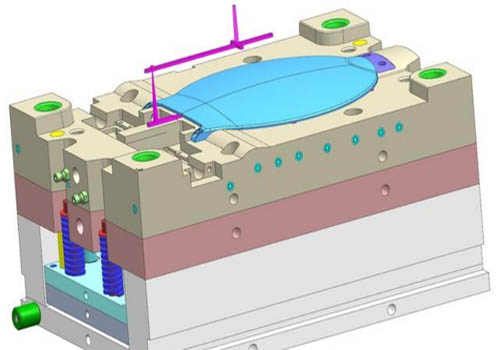

Several solution for mold gate eccentricity,in the mold design, due to the characteristics of the product or the reason that the mold is out of one, it is determined that the main channel must be eccentric.

The eccentricity of the mold gate refers to the eccentricity of the injection nozzle.

For molds that only produce one product, they are often troubled by the problem of eccentricity. The following is a detailed description of the eccentric solutions I have encountered since I started my career, and how to reduce or avoid the problem of eccentricity of KO holes.

Improvement of KO hole eccentricity in mold structure

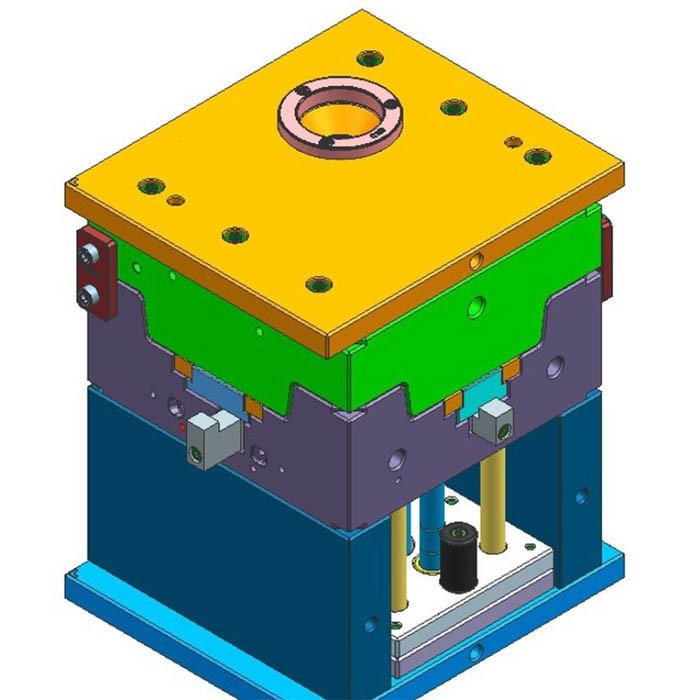

1. use hot runner

In this case, the more common practice now is to use the hot runner method to solve. Pass through the hot runner so that the sprue is at the center of the mold. There are many hot runners used, and the technology is mature. The hot runners produced by Huangyan are not expensive. There are several hundred yuan per point. If you buy 1,000 yuan per point, the quality is very good.

It can be solved with a hot runner, and it also saves the action of the stripping plate.

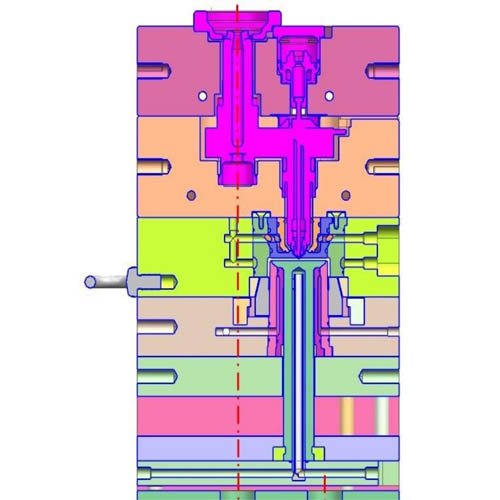

2. increase the upper and lower double plates

No hot runner is used. The general practice is to increase the upper and lower double plates, and put two support columns on one side. This way the nozzle is aligned with the mold and still in the center.

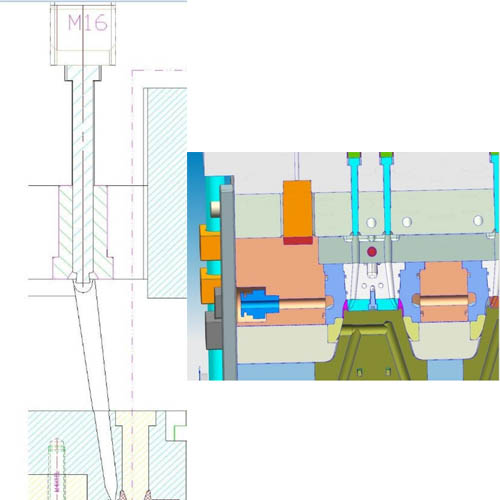

3. Make the sprue sleeve at an inclined angle

Another method is to make the sprue sleeve oblique. The gate sleeve is non-standard. It looks like a straight gate from the outside, but it is actually inclined. The injection machine is also still in the middle of mold. This method is established in theory and is also established in reality, but there are really few practical applications of this method. Some people say that the injection molding machine nozzle sealing material is not easy to seal and easy to run. If your sprue sleeve is done well, there will be no leakage during injection molding. It is rare to make the sprue sleeve inclined.

Design points of inclined sprue sleeve: a. The angle of inclination depends on the toughness of the material. For example, ABS can be used at 15 degrees; b. The spherical surface of the inclined sprue sleeve needs to be placed at a good angle and then milled with a knife.

It is mentioned above that the gate sleeve of the large nozzle is made at an inclined angle. In fact, the flow channel of the small nozzle can also be made oblique.

4. make him eccentric

Of course, there is also a way to make him eccentric. This is not very good for the injection molding machine, and it does not matter when trying out the mold. Because you only played four or five dies, and at most 40 or 50 dies, it doesn’t matter. When the customer took it for injection molding, he made tens of thousands or even 200,000 to 300,000 molds. In this way, after you have played tens of thousands of molds, he has an influence on the Green column of the injection molding machine. When the clamping force is locked, due to mold is eccentric, the force will be uneven, this will affects the Green column and not good for the injection machine. However, there are many such practices in actual mold manufacturing, of course, they are generally small molds.

5 .change the 1-cavity mold into a 2-cavity mold

Finally, there is a way to change the 1-cavity mold into a 2-cavity mold. Of course, it is not feasible. Generally, the number of cavities and the price have been negotiated with the customer.

6. Keep the sprue sleeve in the center of the mold by means of eccentric mold frame

This method is quite balanced, and some templates will be larger and a bit wasteful. If the eccentricity is not too much, it is recommended to use it.

7. If the size of the eccentricity is not very large, just make the eccentric one directly

The recommended eccentric size should not exceed 30mm, and the smaller the mold, the smaller the value

8. Using the KO hole for dislocation, it is a bit awkward to hang the mold below on the injection molding machine

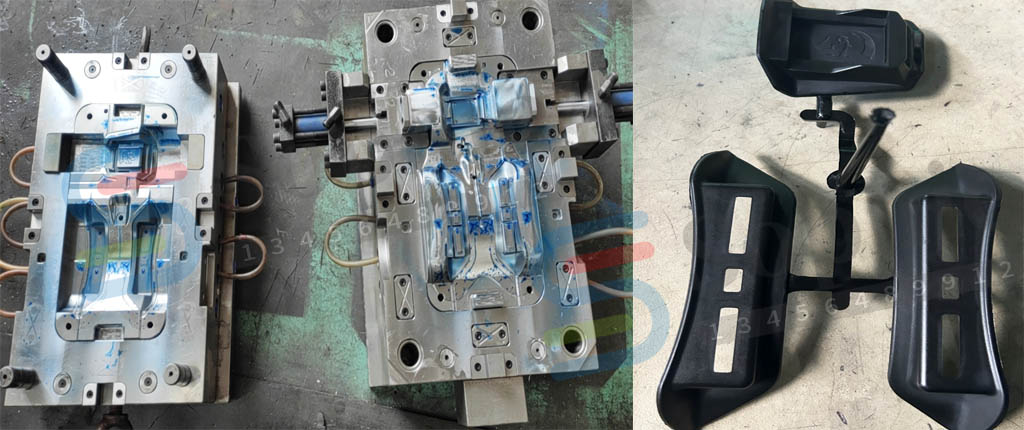

9. Pulled by a small nozzle, it is suitable for large products that must use a side gate

The situation encountered in actual work can be dealt with in combination with the same method above. Also note that if there is a push tube, it cannot coincide with the position of the KO hole.