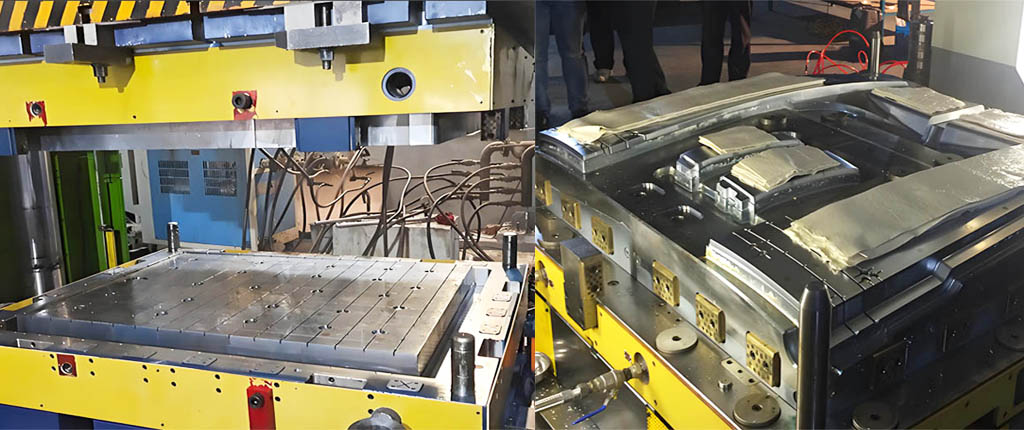

SMC molds Insulation measures and cooling methods,In the compression molding process of SMC (sheet molding compound) molds, heat preservation and cooling are crucial steps. Good insulation measures and cooling methods can not only improve production efficiency, but also significantly improve the quality of products. This article will introduce in detail the insulation measures and cooling methods of SMC molds.

Table of Contents

ToggleSMC Molds Insulation measures

Insulation is the key to ensuring uniform and stable mold temperature, which directly affects the quality of SMC products.There are many insulation measures for SMC molds. Aluminum hydroxide insulation cotton can be wrapped with asbestos cloth or glass cloth for insulation. There is also a kind of insulation coating on the market, which is an ideal material for mold insulation. It is a mixture of medium and long fibers, slurry and an insulation foam material. It has moderate viscosity and is easy to apply. This material is often used as an insulation layer material for chemical and heating pipes and is slightly alkaline. After use at 150 degrees Celsius, no negative effects such as burning, melting, and odor were found. At the same time, the material is very light and has strong plasticity, which can easily form a more beautiful mold surface. The following are common insulation measures:

Use insulation plate

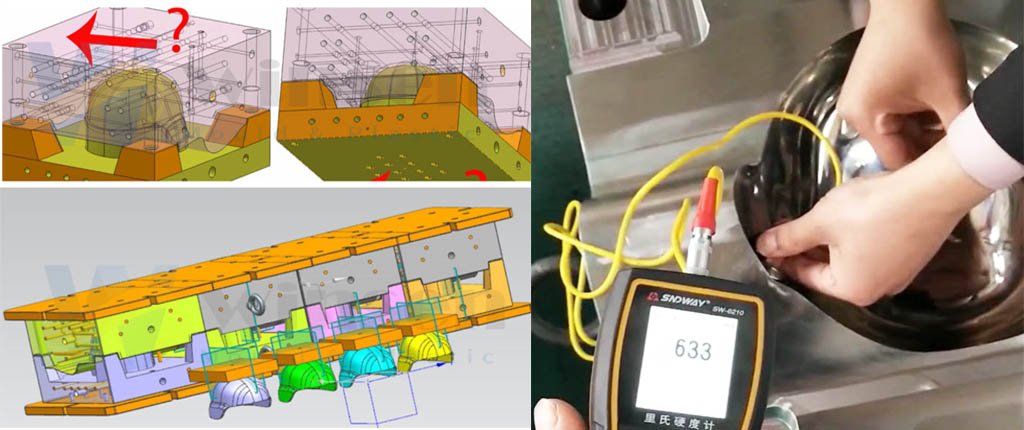

Installing insulation plate between mold and injection molding machine can effectively prevent heat loss and keep the temperature in mold uniform. Insulation board usually uses materials with low thermal conductivity, such as ceramic fiber, glass fiber, etc. These materials not only have good thermal insulation performance, but also are resistant to high temperature and corrosion.

Mold heating system

Heating elements, such as electric heating tubes and electric heating plates, can be embedded in the mold, and the mold temperature can be accurately controlled by the thermostat. This method can heat the mold quickly and evenly to ensure the stability of molding temperature.

Insulation cover

Covering the outside of the mold with insulation cover can effectively reduce heat loss. Insulation cover is usually made of insulation cotton or insulation material, which is light and can withstand high temperature, and is widely used in various SMC molds.

Insulation coating

Coating a layer of insulation material on the surface of the mold can enhance the insulation effect of the mold. Commonly used insulation coating materials include ceramic coatings, high-temperature insulation paints, etc. These materials can effectively isolate heat conduction and improve the thermal efficiency of the mold.

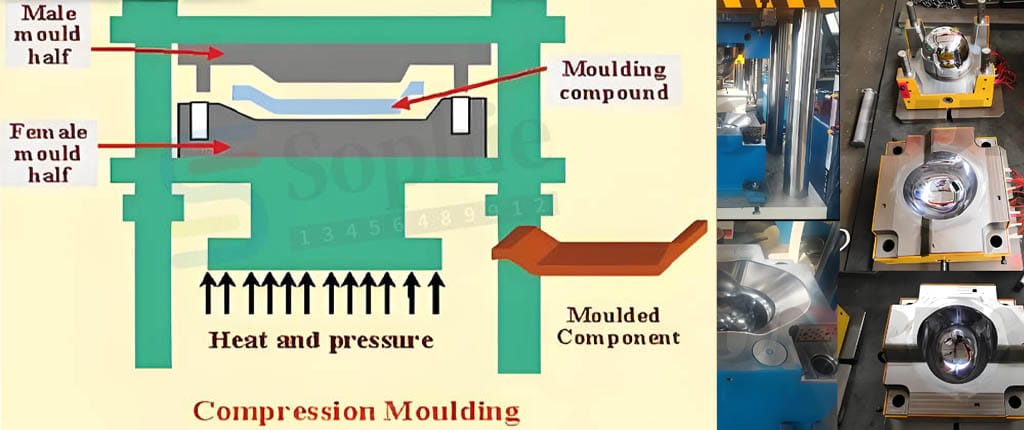

Cooling method

Cooling is also an indispensable part of the SMC molding process. Effective cooling methods can ensure the dimensional accuracy and surface quality of the product while shortening the molding cycle. The cooling method of SMC mold is very simple. Water cooling is the cooling method used by most molds, but it also has its disadvantages, such as requiring good pipeline sealing, keeping the upper and lower water pipes unobstructed, and wasting a lot of water resources. When the cooling temperature is higher than 100 degrees Celsius, steam explosion is prone to occur. The advantage is that the heat capacity is large and the temperature can be reduced. Air cooling is an ideal cooling method. In contrast to water cooling, it does not require strict pipeline sealing, there is no waste of resources, and it can cool SMC molds with temperatures higher than 100 degrees Celsius. The cooling speed can be determined by the flow rate of the gas, and the source is simple and convenient. Large-scale production workshops can obtain a more convenient gas source.The following are common cooling methods:

Water cooling system

Water cooling system is the most common mold cooling method. By opening a cooling water path inside the mold, the cooling water circulates in the water path and takes away the heat in the mold. The advantages of the water cooling system are fast cooling speed and precise temperature control, which is suitable for most SMC molds.

Air cooling

Air cooling is usually used for small molds that do not have high cooling requirements. By setting up fans or cooling ducts around the mold, air convection is used to take away the heat from the mold. This method is simple and easy to implement, but the cooling efficiency is relatively low.

Oil cooling system

For molds that require precise control of cooling temperature, an oil cooling system can be used. The oil cooling system uses thermal oil as the cooling medium. The thermal oil is sent into the cooling oil circuit inside the mold through an oil pump to take away the heat. The cooling effect of the oil cooling system is stable and suitable for high-precision molds.

Coolant spray

In some special cases, coolant spraying can be used to cool the mold. The coolant is sprayed on the mold surface through a nozzle to quickly remove the heat. This method has a significant cooling effect, but the operation is relatively complicated and is suitable for situations where rapid cooling is required.

Insulation and cooling are aspects that cannot be ignored in the SMC mold molding process. By rationally selecting insulation measures and cooling methods, production efficiency can be significantly improved and product quality improved. In actual production, enterprises should select the most suitable insulation and cooling solutions based on specific circumstances, comprehensive consideration of cost, effect and other factors, in order to achieve the best production efficiency. It is hoped that the introduction of this article can provide valuable reference for relevant practitioners and help the further development of SMC mold technology.