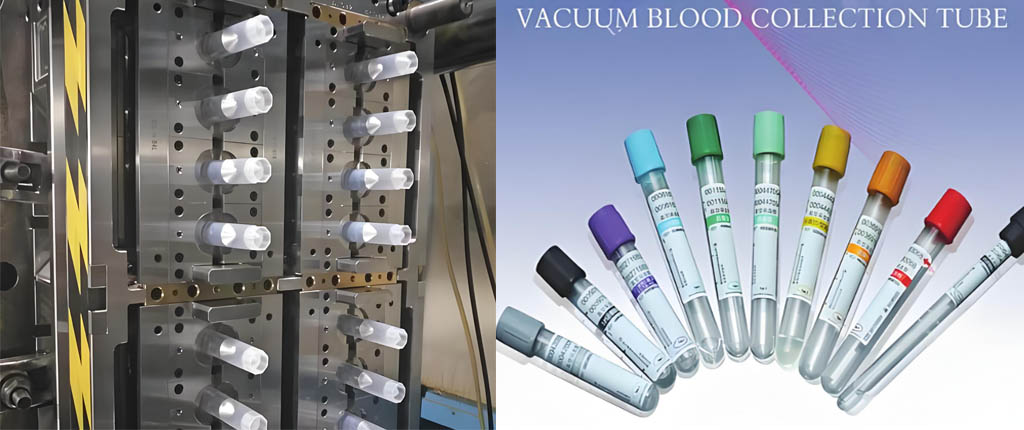

solutions for blood collection tube molds,With the rapid development of the medical and health industry, blood testing has become an important means of diagnosing and monitoring diseases. As a key component of blood testing, the quality and production efficiency of blood collection tubes directly affect the accuracy of test results and the efficiency of medical resource utilization. my country’s medical device mold market environment is at a stage where opportunities and challenges coexist. As a young member of the medical device family, vacuum blood collection tubes have huge market demand.

Table of Contents

ToggleThis article will explore how to improve the production process of blood collection tube molds through intelligent technology to achieve more efficient and accurate production.How can we avoid problems such as low production efficiency, backward technology, and uneven product quality during large-scale mass production, and ensure the stability and traceability of production efficiency and product quality?

Importance of blood collection tube molds

Blood collection tube molds are the core tools for producing blood collection tubes. Their design and manufacturing quality are directly related to the sealing, crack resistance and ease of use of blood collection tubes. Traditional blood collection tube mold production relies on manual operation and experience judgment, which has problems of low efficiency and unstable quality.

As the country has made stricter control over the safety and quality of medical device products, each manufacturer has higher requirements for production and manufacturing. The production of vacuum blood collection tubes must move towards automation and scale in order to meet domestic and international market demand and production requirements.

What innovative technologies does blood collection tube mold have in the medical industry?

Automated production

With the growing demand for blood collection tubes in the medical industry, automated production has become one of the key technologies. Automated production lines can improve production efficiency, reduce labor costs, and ensure the consistency of product quality. High-speed medical injection molding machines provide high-performance blood collection tube automated production equipment and overall solutions, which can achieve large-scale mass production while ensuring the stability of production efficiency and product quality

By introducing automated production lines, mass production of blood collection tube molds can be achieved. Automated equipment can work 24 hours a day, greatly improving production efficiency.

WS MOLD has rich experience and advanced technology in the medical injection molding industry, specializing in providing high-performance blood collection tube automated production equipment and overall solutions (high-speed medical injection molding machines, blood collection tube molds, other auxiliary machines and intelligent manufacturing systems).

It has the characteristics of high cleanliness, high precision, high efficiency, and high energy saving, and is very suitable for such medical products with high production requirements.

- Medical injection molding machines use AC servo motors, gears, ball screws, gear belts and other transmission devices. Compared with traditional servo machines, its advantage is that the injection unit uses a new all-electric drive module.

- During the injection molding process, the injection pressure is collected by a high-precision pressure sensor and centrally fed back to the control processing system. Since the pressure sensor is directly connected to the screw, the intermediate link is avoided, thereby achieving higher sensing accuracy and rapid response. The whole machine has high repeatability positioning accuracy and is suitable for the production of high-precision medical blood collection tubes.

It also uses a distributed power source, which can realize multiple actions working simultaneously, greatly shortening the blood collection tube molding cycle and improving production efficiency.

This model uses a hydraulic motor and injection cylinder, no oil leakage problem, keeps the workshop clean and easy to maintain; in addition, the activation resistance generated by the servo motor is small, the acceleration and deceleration are easy to control, and the low noise is more environmentally friendly. And it reduces energy consumption loss by 30%-50% compared with traditional models.

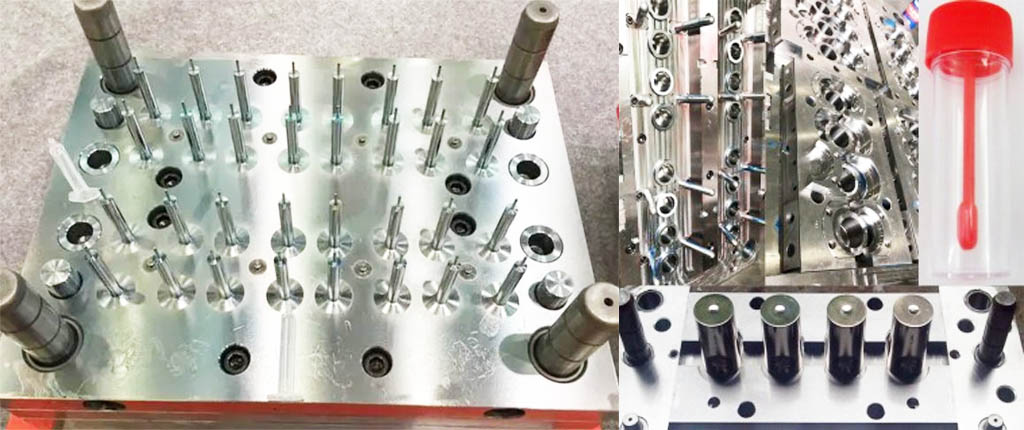

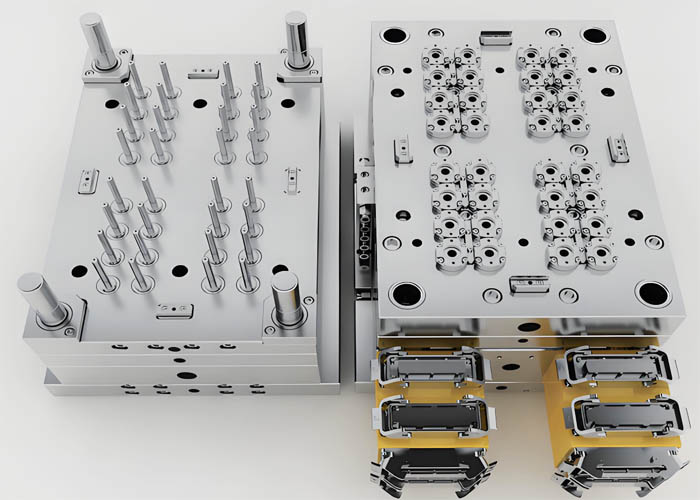

Mold design optimization and Precision machining

Precision mold design is the key to ensuring the quality of blood collection tubes. The mold uses high-hardness steel such as S136 produced by Assab, Sweden, and a gas-sealed needle valve full hot runner system to ensure smooth cavity filling and balanced melt flow, thereby improving the quality of plastic parts.

Using computer-aided design (CAD) software, designers can create a three-dimensional model of the blood collection tube mold in a virtual environment. This can not only shorten the design cycle, but also predict the performance of the mold in actual production through simulation analysis.

Using CNC machine tools (CNC) for mold processing can ensure the dimensional accuracy and surface finish of the mold, reduce human errors, and improve the consistency and reliability of the mold.

Material innovation

PET plastics are widely used in the manufacture of blood collection tubes due to their advantages such as lightness, durability and cost-effectiveness. The use of PET plastic tubes has promoted the market’s shift from glass blood collection tubes to plastic vacuum blood collection tubes.

Quality control system

The integrated quality control system can monitor key parameters in the production process, such as temperature, pressure and speed, in real time to ensure the production quality of the mold.

Intelligent monitoring system

Integrated quality control systems and production efficiency monitoring platforms, such as Shotscope™ NX, can monitor key parameters in the production process in real time, predict and solve potential production problems.

Using machine learning and artificial intelligence algorithms, the production process can be optimized based on historical data, and potential production problems can be predicted and solved.

Research and development of new blood collection tubes

New blood collection tubes such as needle-type non-destructive blood collection tubes and self-closing blood collection tubes have appeared on the market. These innovative products have improved the efficiency and comfort of blood collection and are expected to further expand the market size.

Needle-free vacuum blood collection system

Some manufacturers are developing needle-free vacuum blood collection systems to improve patient comfort and reduce the risk of infection. This is an innovative direction of blood collection technology.

The application of these innovative technologies not only improves the production efficiency and product quality of blood collection tubes, but also meets the high standards of safety and accuracy in the medical industry.

Advantages and features of blood collection tube mold production

Product: high light transmittance, smooth and clean surface without dents and eccentricity

- Cycle: 8s

- Wall thickness: 0.82mm

- Material: PET

- Number of cavities: 32 cavities

- Production capacity: about 345,600 (24 hours)

collection tube molds can not only improve production efficiency and product quality, but also bring broader social benefits to the medical and health industry. With the continuous advancement of technology, we have reason to believe that intelligent production will become the mainstream trend of the future medical manufacturing industry.

With years of technological accumulation, WS MOLD is committed to the development of advanced injection molding solutions in the field of medical supplies, and continues to move towards intelligence, environmental protection and diversification. With precise manufacturing equipment and continuous technological innovation, it provides new functions for the high-quality development and transformation and upgrading of the industry, and helps the high-quality development of the industry.