The process of making bulletproof helmet mold,in modern warfare and police work, bulletproof helmets are one of the key pieces of equipment that protect the lives of soldiers and law enforcement officers. However, few people pay attention to the craftsmanship behind these helmets. Bulletproof helmets are an important piece of personal protective equipment that can effectively protect the user’s head from external impacts and shrapnel. The manufacturing process of a bulletproof helmet plays a vital role in its quality and performance. Today, we will delve into the production process of bulletproof helmet molds, reveal how they play a vital role, and help readers understand its production process and key steps.

Table of Contents

TogglePrototyping Design bulletproof helmet mold

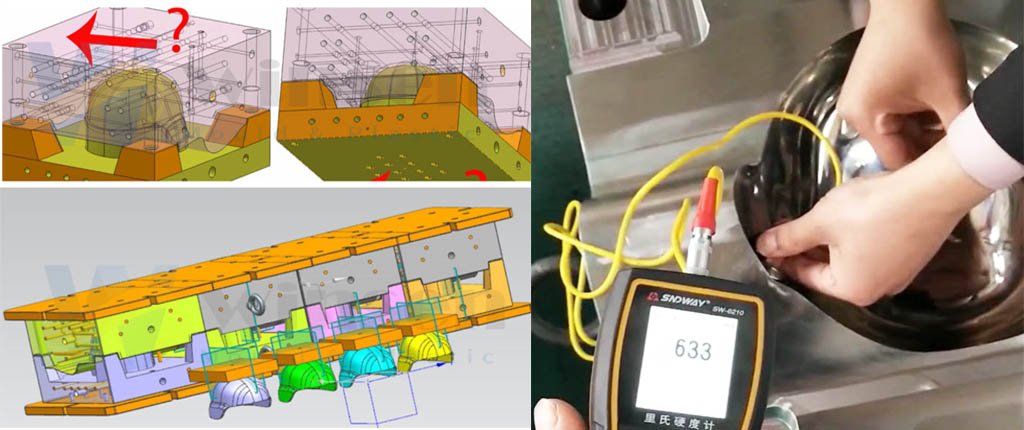

The first step in making a bulletproof helmet mold is to design a prototype. This stage involves transforming ideas into workable designs. Engineers use computer-aided design (CAD) software to create accurate three-dimensional models that take into account the helmet’s shape, size and materials.

Steel Selection

Choosing the appropriate material is crucial for making a bulletproof helmet mold. Typically, engineers choose high-strength metal alloys or special steel to ensure the mold is sufficiently durable and precise.

Steel Selection

Choosing the appropriate material is crucial for making a bulletproof helmet mold. Typically, engineers choose high-strength metal alloys or special steel to ensure the mold is sufficiently durable and precise.When making a bulletproof helmet mold, the choice of material is very important. Generally speaking, commonly used materials include P20 steel, 718 steel, H13, etc. H13 mold steel has good hardness up to 50HRC after vacuum quenching, and can produce high-quality molds that can withstand pressure.

Make the bulletproof helmet mold

Once the design is finalized and the appropriate materials selected, making the bulletproof helmet mold begins. This often involves using advanced tools such as numerically controlled machines (CNC) or electrical discharge machining (EDM) to cut or machine molds based on CAD designs.

Precision machining

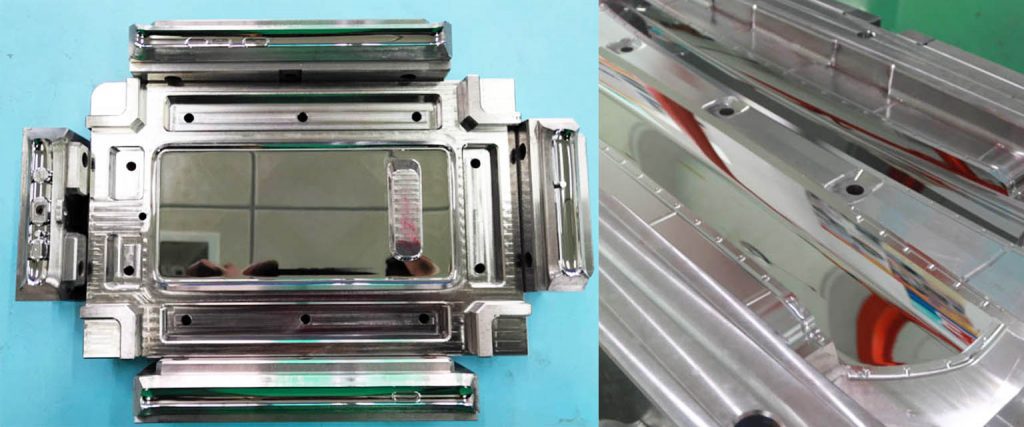

During the production process, precision machining is the key to ensuring the quality of the bulletproof mold. Craftsmen use micron-level precision to ensure every detail of the mold is consistent with the design. This includes precise control of surface finish and dimensional accuracy.

Quality inspection

After production is completed, the bulletproof helmet mold needs to undergo strict quality inspection. This includes using 3D measuring instruments to check the size, shape and surface quality of the mold to ensure it meets design requirements.

Testing and Validation

Finally, the completed bulletproof helmet mold needs to be tested and verified. This includes using molds to produce helmets and conducting various experiments and tests on the helmets to ensure they meet ballistic protection requirements and safety standards.

Manufacturing Stage for Bulletproof Helmet Mold Compression Mold

Molds are usually manufactured using high-strength steel or other high-temperature-resistant materials to withstand the high pressures and temperatures during the molding process. Precision machining ensures the dimensional accuracy and surface finish of the mold, which is crucial to the quality of the final product.

The manufacturing process of bulletproof helmet molds is a complex and precise process that requires the selection of appropriate materials, combined with advanced design technology and specialized manufacturing processes. By following the correct production steps, you can get high-quality molds, and then produce high-quality bulletproof helmets to provide the best protection for soldiers and law enforcement officers. I hope the introduction in this article will be helpful to readers.

As a company specializing in the production of bulletproof helmet molds, we are committed to providing high-quality products and services. We have an experienced and skilled team that is proficient in the latest design technology and manufacturing processes. Through continuous R&D and innovation, we are able to not only meet our customers’ needs, but also exceed their expectations. Our products undergo strict quality control and testing to ensure they meet the highest standards and requirements. Whether it is an individual user or a government agency, we can provide them with customized solutions to meet their specific needs and requirements. Our goal is to provide customers with the best product quality and the most satisfactory service, providing solid support for their safety and protection.