1.Daily basic tips for mould maintenance

(1). It is necessary to clean up the concrete residue on the mold in time after work every day;

(2). Every day, it is necessary to check whether the screws of the mold are loose and tighten them in time;

(3). It is necessary to check the welding part of the mold every day to see if there is any open welding and repair it in time;

(4). It is necessary to check whether the mold positioning shaft and the positioning sleeve are worn every month. If any wear is found, it needs to be replaced in time;

(5). The replaced mold needs to be oiled on the indenter and mold frame to prevent rust, and placed horizontally on the ground.

2.The purpose of mould daily maintenance

4). The processed mold is better cleaned by electrolytic ultrasonic cleaning method. It also plays the role of rust prevention while cleaning.

1). Purpose: To keep the mold in the best performance state and extended the service life to guarantee the normal production.

2). Scope of application: Repair and maintenance of applicable molds.

3). Regular inspection and maintenance: Regular maintenance and inspection by mold maintenance, upper and lower mold personnel are required.

3.The main classification of mould daily maintenance

(1). Daily routine inspection and maintenance:

1). Whether the running mold is in normal state

A. Whether there is low voltage mode locking protection;

b. Are moving parts such as guide posts, ejector rods, and travel positions worn, and are they lubricated well? It is required to refuel at least 12 hours, and the number of refueling should be increased for special structures.

c. Whether the screws and clamping clamps of the fixed template of the mold are loose;

2). Normal production condition: check whether the defect of the product is related to the mold;

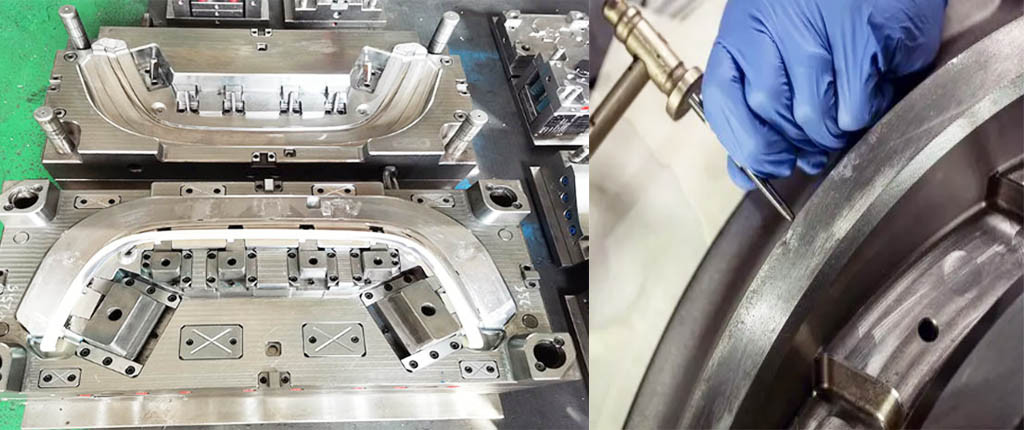

3). When getting off the machine, conduct a comprehensive inspection of the mold and carry out anti-rust treatment: dry the water in the cavity, core, ejector mechanism and row position and spray mold anti-rust agent or apply butter.

4). The mold after dismounting should be placed in the designated place and recorded:

A. Mold condition: intact or to be repaired.

B. Anti-rust treatment method when lowering the mold.

(2). Quarterly routine inspections:

It is mainly to clean and maintain the molds that have not been used for more than two months.

1). Open the mold and check the internal anti-rust effect. If there is an abnormal situation, the anti-rust treatment must be carried out again. If mold isn’t used for a long time,it have to coated with butter.

2). Put it back in place and make a record.

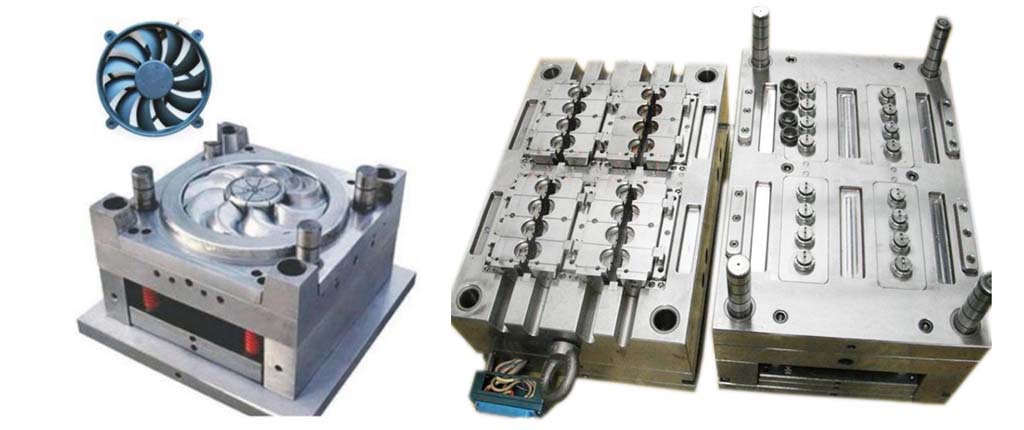

Regular maintenance of the mold plays a vital role in the service life of the mold. Injection molds are the main investment in the plastics processing industry, they constitute the vast majority of a company’s assets and are the basis for production, economic success and technological progress. Therefore, a good mold maintenance system can ensure that the management of molds is in an optimal state, and at the same time evaluate the cost of maintenance to maximize commercial benefits.

Mold is a kind of process equipment that is widely used in the middle stage of industrial production. The development of modern industry and the improvement of technical level are inseparable from molds. According to statistics, 75% of the rough machining of industrial parts and 50% of the finishing are completed by mold forming. According to its type, it can be divided into: cold stamping mold, injection mold, die-casting mold, rubber mold, etc.