What are the thermosetting plastics

Thermosets are plastics that undergo a chemical reaction during the heating and curing process, forming a three-dimensional network structure. Once cured, they do not melt or deform when heated like thermoplastics. This property gives thermosets many unique properties and applications.

Table of Contents

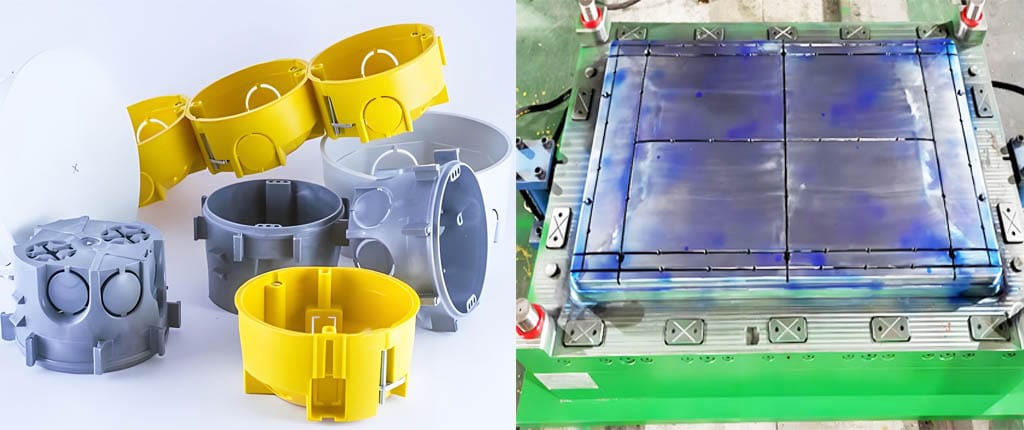

ToggleCompression molding is a widely used technology in the field of plastic processing, and it is particularly suitable for the molding of thermosetting plastics. This process uses high temperature and high pressure to shape the material into the desired shape, and once formed, the material will retain its state and will not melt again.

Which thermosetting plastics are used in plastic compression molding

The following is a detailed introduction to the common thermosetting plastics commonly used in compression molding:

Phenolic resin (PF)

As one of the earliest plastics, phenolic resin is very common in compression molding, especially for the manufacture of electrical insulation parts and daily products

Urea-formaldehyde resin (UF)

This material is commonly used to make tableware, bottle caps and other daily necessities and mechanical parts, and can also be used as an adhesive.

Melamine-formaldehyde resin (MF)

Also known as melamine, this plastic has good water resistance and chemical resistance and is often used in tableware and industrial products.

Unsaturated polyester resin (UF)

It is usually added with reinforcing materials such as glass fiber, commonly known as fiberglass, and is used to manufacture products with high strength requirements.

Epoxy resin (EP)

Known for its excellent adhesion and electrical properties, it is often used in the packaging of printed circuit boards and electronic components.

Silicone resin (SI)

This resin is known for its heat resistance and cold resistance and is suitable for the production of electronic industrial components.

Polyurethane

Polyurethane can be made into a variety of products, from lightweight thermoplastic elastomers to rigid foam plastics, suitable for use in furniture, packaging materials and construction.

Plastic Compression Molding Process

The compression molding process usually includes the following steps:

- Preheating: preheating the mold and material to ensure that the material is heated evenly in the mold.

- Feeding: adding a predetermined amount of plastic material to the mold.

- Closing the mold: the mold closes and begins to apply pressure and heat to the material.

- Venting: after a certain period of time, the mold is released to release the air and volatiles in the mold.

- Curing: the material is kept at the molding temperature for a period of time to allow the condensation reaction of the resin to reach the desired degree of cross-linking.

- Demolding: after the product is cured, the mold is opened and the finished product is taken out.

Applications of Compression Molding

The compression molding process is particularly important in industries such as automotive, aerospace, electrical and construction because it is able to produce large, durable and complex components. Although this process can be automated in some cases, some steps still require human intervention due to the manual handling of materials and molds.

Development Trends

With the development of the plastics industry, compression molding process technology is also constantly improving. Future development directions may include:

- High efficiency: Improve compression molding efficiency by optimizing process flow and improving mold precision.

- Intelligent: Use automation equipment and control systems to achieve intelligent control of mold temperature, pressure and other parameters.

- Environmentally friendly: Use environmentally friendly plastic raw materials and green production processes.

Compression molding is a reliable and economical manufacturing method, especially suitable for the production of thermosetting plastic parts. With the continuous advancement of technology, the application scope of this process in modern manufacturing is still expanding.

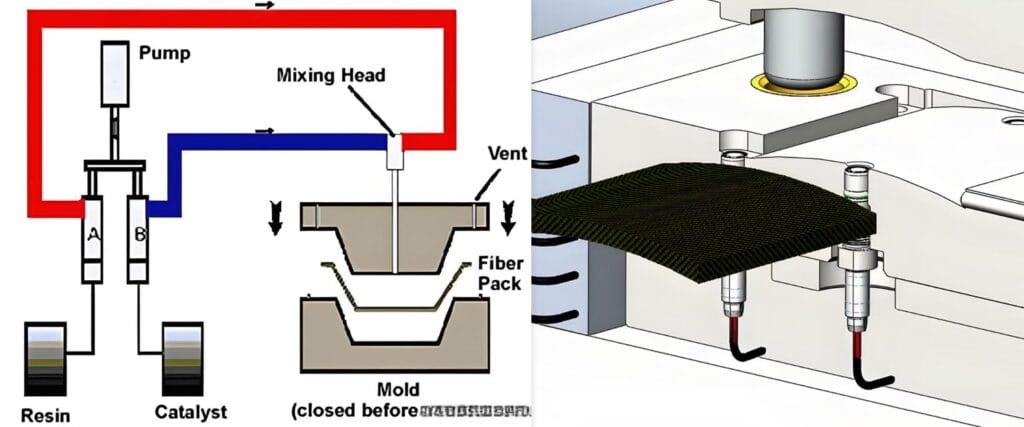

Thermosetting plastic molding methods

The processing of thermosetting plastics usually includes compression molding, transfer molding, injection molding, extrusion molding, etc. In these processes, the material is heated to a certain temperature, and then pressure is applied in the mold to solidify it. Due to its irreversibility, the temperature and pressure need to be precisely controlled during the processing to ensure product quality.

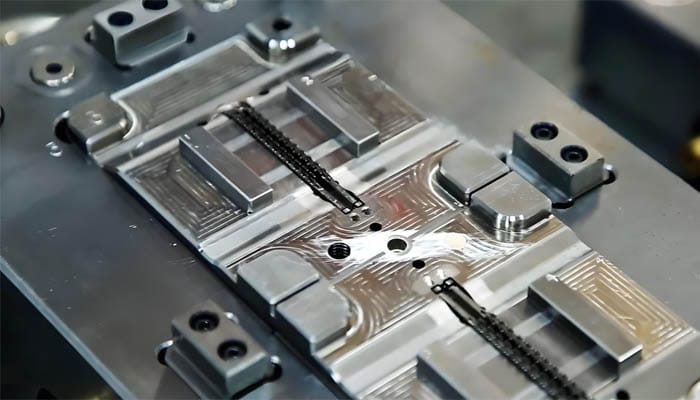

When designing a mold for compression molding, multiple factors need to be considered, including material fluidity, mold temperature, pressure, and holding time. Optimization of these parameters is critical to ensuring product quality and production efficiency. In addition, the design of the mold also needs to consider the preheating, venting, and curing processes of the material to ensure that the parts can achieve the required mechanical properties and dimensional accuracy after compression molding.

In general, compression molding is a reliable and economical manufacturing method, especially suitable for the production of thermoset plastic parts. With the continuous advancement of technology, the application scope of this process in modern manufacturing is still expanding.