The use of molds in life is very extensive, and there are many types of them. Although it is only a model, many products are produced based on molds, and the role of molds is becoming more and more important. What about its design and manufacturing process?

Table of Contents

ToggleThe mould design is not made out of thin air, but is designed according to certain requirements. Whether it is material, shape, size, and smoothness, it must be completed according to the requirements.

In selecting the material of the mould

The customer’s usage needs and manufacturing costs are mainly considered.

In terms of use requirements

General users will focus on high hardness and wear resistance, which is closely related to heat treatment. If the heat treatment is not done well, the hardness requirements will not be met. If the brittleness is too large during the heating process, there are also It may cause the mould to explode and rupture when heated, so the heat treatment process is also critical.

In terms of manufacturing cost

This kind of fine processing and manufacturing cost also occupies a large proportion. The selection of materials must pay attention to the heating performance to avoid wasting materials and increasing the manufacturing cost.

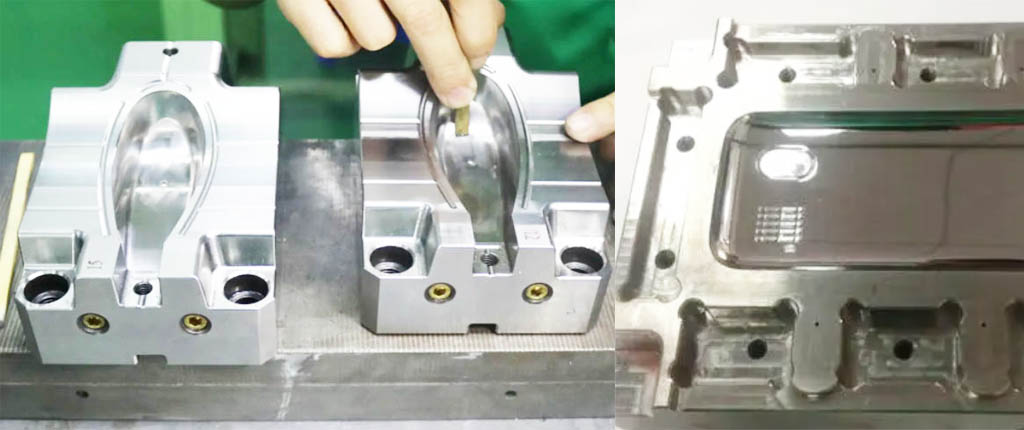

Manufacture of the main parts of the mould: First, pay attention to the grinding of the surface and interior of the mould; secondly, when processing the mold, pay attention to the wire cutting process, because the diameter of the metal wire is relatively small and the difficulty is relatively high. Pay attention; finally, when discharging and heating, pay attention to avoid the heat generated by the spark when the electrical appliance is working to hurt the eyes.

After all processing is completed and the final inspection is passed, the complete mold is considered a success. In order to ensure the quality of the mould, we should choose a regular professional mould manufacturer.

Mould design and manufacturing process

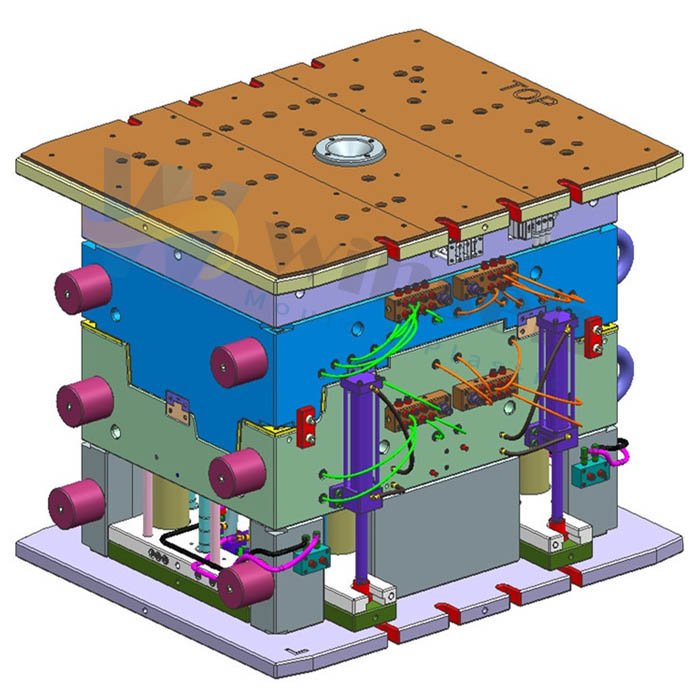

In fact, it is the process of mold from production to put into use, that is, the process of processing a material into a mold. The main process of this process is: determination of mold structure plan – mold design – formulation of process flow – organization of production parts – mold assembly – mold trial and adjustment – inspection and packaging.

The main content of mould design and manufacturing

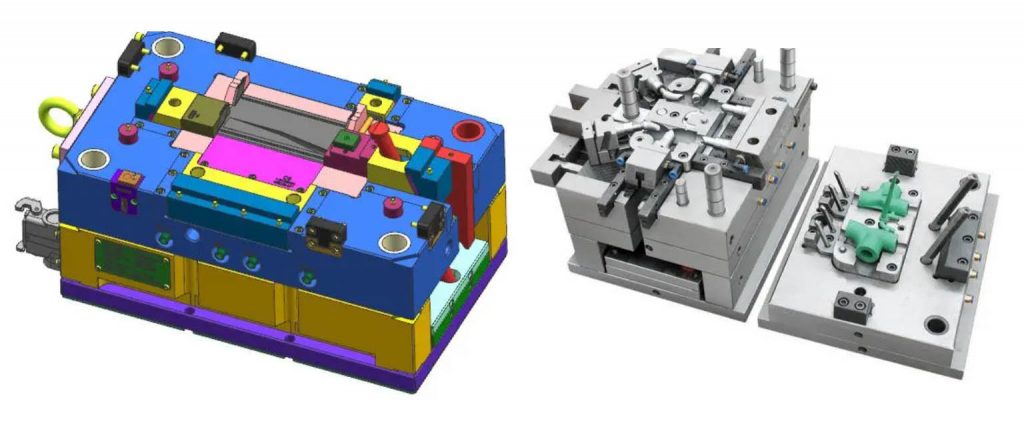

This content mainly includes two aspects, the first is the design of the mold, and the second is the manufacture of the mold. Mold design mainly includes: plastic mold design, stamping die design, etc. The mold manufacturing includes both traditional processing technology and emerging processing technology and special processing: traditional processing mainly includes: cutting processing, casting processing, etc., special processing includes EDM, electrochemical processing, ultrasonic processing and laser processing wait.

The development trend of mould design and manufacturing

With the development of science and technology, the mold is also in continuous progress. During the “Eleventh Five-Year Plan” period in my country, the development of mold products mainly includes the following categories:

(1) Car panel mold: This is a panel mold for automobiles, with complex structure and high requirements.

(2) Precision stamping die: This kind of abrasive includes multi-station progressive die and fine punching die, with high service life and requirements.

(3) Large precision plastic molds: including large injection molds for automobiles and home appliances.

Mold design is not fabricated out of thin air, it is designed according to certain requirements, whether it is material, shape, size, smoothness and fineness, it must be completed according to requirements.

After all the processing is completed and the final inspection is passed, the complete mold is considered a success. In order to ensure the quality of the mold, we should choose a regular professional mold manufacturer.