What is moulds ? A mould is a tool used to make a shaped item.The use of molds in life is very extensive, and there are many types of them.Although it is only a model, many products are produced based on moulds, and the role of molds is becoming more and more important.

The mold design is not made out of thin air, but is designed according to certain requirements. Whether it is material, shape, size, and smoothness, it must be completed according to the requirements.

Mould are shaped tools

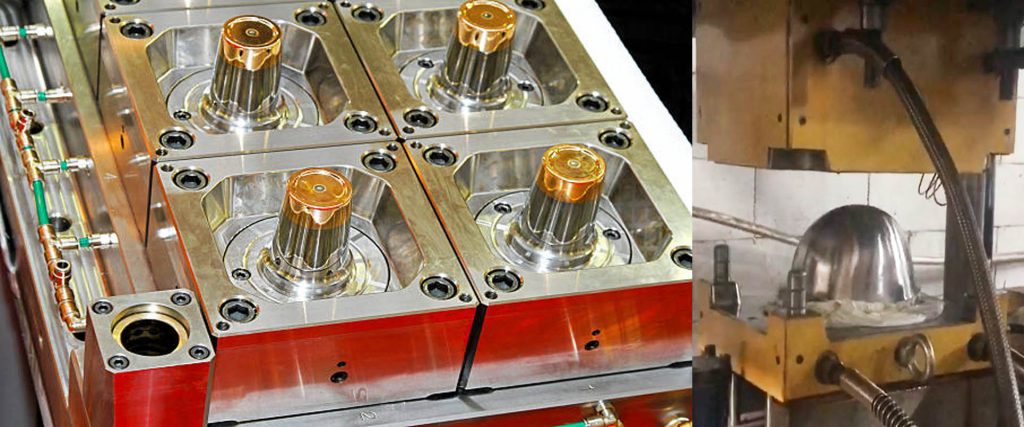

A mold is a model shape tool for mass production of identical products. After the mold is finished, inject some materials into it, and then open the mold to get the expected product. The common plastic molds are often iron molds. Inject molten plastic into it, cool it for a while, and take it out to be a molded plastic product.

Mould is the “mother of industry”

In addition to the mold itself, it also needs a mold base, a mold base, and a mold core to cause the ejection device of the product, etc. These parts are generally made into a general-purpose type. Known as the “mother of industry”, a mold is a cavity tool with a certain shape and size. It is used in conjunction with various systems or auxiliary mechanisms in the mold to fill various high-temperature liquid materials into the mold cavity. Industrial parts can be produced with a specific shape, size, function and quality.

Mold application industry

Molds are widely used in electronics, automobiles, motors, instruments, electrical appliances, instrumentation, home appliances and communications products, and 60%-80% of the parts and components are formed by molds. The high precision, high complexity, high consistency, high productivity and low consumption of parts produced by molds are unmatched by other processing and manufacturing methods.

How to choose mold material

In selecting the material of the mold, the customer’s usage needs and manufacturing costs are mainly considered.

(1). In terms of usage requirements

general users will focus on high hardness and wear resistance, which is closely related to heat treatment. If the heat treatment is not done well, the hardness requirements will not be met. If the brittleness is too high during the heating process It is also possible to cause the mold to explode and rupture when heated, so the heating process is also critical.

(2). In terms of manufacturing cost

This kind of fine processing and manufacturing cost also occupies a large proportion.The selection of materials must pay attention to the heating performance to avoid wasting materials and increasing the manufacturing cost.

Attention points for main parts of the mold manufacturing

First of all, pay attention to the grinding of the surface and interior of the mold;

Secondly, when processing the mold, pay attention to the wire cutting process, because the diameter of the wire is small and the difficulty is relatively high, so special attention should be paid to it;

Finally, it is necessary to pay attention to avoid injury to the eyes caused by the heat generated by the spark when the electrical appliance is working.

After all processing is completed and the final inspection is passed, the complete mold is considered a success. In order to ensure the quality of the mold, we should choose a regular professional mold manufacturer.

Classification of molds

The molds are divided into three categories according to the different materials to be formed. Metal molds, plastic molds, and their special molds.

Hardware dies are divided into: including stamping dies (such as blanking dies, bending dies, deep drawing dies, turning dies, shrinkage dies, undulating dies, bulging dies, shaping dies, etc.), forging dies (such as die forging dies, upsetting dies, etc.) Forging dies, etc.), extrusion dies, extrusion dies, die-casting dies, forging dies, etc.; non-metallic dies are divided into: plastic dies and inorganic non-metallic dies.

According to the different materials of the mold itself, the mold can be divided into: sand mold, metal mold, vacuum mold, paraffin mold and so on. Among them, with the rapid development of polymer plastics, plastic molds are closely related to people’s lives. Plastic molds can generally be divided into: injection molding molds, extrusion molding molds, compression molding molds, gas-assisted molding molds, and so on.

Molds are various molds and tools used in industrial production to obtain the desired products by injection molding, blow molding, extrusion, die casting or forging, smelting, stamping and other methods. This tool is made up of various parts, and different molds are made up of different parts. It mainly realizes the processing of the shape of the article by changing the physical state of the formed material.

Customized production of various types of plastic injection molds and composite compression moulds,welcome contact.