Plastic mold is the abbreviation of a combined mold for compression molding, extrusion molding, injection molding, blow molding and low foam molding. The coordinated changes of the mold convex, concave mold and auxiliary molding system can process a series of plastic parts of different shapes and sizes. Plastic mold is named the mother of industry, and current the research of new products will involve plastic.

Table of Contents

ToggleProcessing of plastic molds

During injection molding, the mold is clamped on an injection molding machine, and molten plastic is injected into a molding cavity, where it is cooled and molded.

The upper and lower molds are separated, and the product is pushed out of the cavity and out of the mold through the push-out system.

The mold is closed again for the next injection, and the entire injection process is cycled. It is understood that, as a tool for producing plastic products, a plastic mold consists of several sets of parts, and there is a molding cavity in this combination. In industrial production, plastic molds can press metal or non-metal materials into parts or products of the desired shape. Analysis of the influencing factors of plastic mold manufacturing with extended data.

What is plastic mold manufacturing process

When the parting surface mold is closed, the female mold and the male mold cooperate with each other. The structural parts are sliders, inclined tops and straight tops of complex molds. The precision of plastic molds includes anti-sticking, precise positioning, guide posts, positioning pins, etc. The gating system is located between the nozzle and the cavity of the injection molding machine, and consists of a main runner, a branch runner, a gate and a cold cavity. The shrinkage rate of other plastics and various factors that affect the dimensional accuracy of products, such as mold manufacturing and assembly errors, mold wear, etc. In addition, another, when designing compression molds and injection molds,it have to be considered the process and structural parameters matching with molding machine.

Plastic molds include compression molding and injection molding. They are mainly used for molding thermosetting plastics, and the corresponding equipment is a press molding machine. Compression molding method According to the characteristics of the plastic, the mold is heated to the molding temperature (generally 103-108), and then the measured compression molding powder is put into the mold cavity and the feeding chamber, the mold is closed, and the plastic is under the action of high heat and high pressure. Soft and sticky. After a certain period of time, it is cured into the desired product shape. The difference between injection molding and compression molding,it has a separate charging chamber. The mold is closed before molding, and the plastic is preheated to a viscous state in the feeding chamber. Under pressure, the adjustment is extruded into the cavity and hardened. Compression molds are also used to mold some special thermoplastics, such as refractory thermoplastics (such as polyvinyl fluoride) blanks (cold compression molding), resin lenses with high optical performance, etc. The die is mainly composed of a cavity, a feeding cavity, a guide mechanism, a push-out component, and a heating system. In the packaging of electronic components,injection molds are widely used. The materials used in the manufacture of compression molds are basically the same as injection molds. Such as trash can molds.

Injection molds are molds used to form plastic container hollow products (such as beverage bottles, daily chemical products and other packaging containers). According to the process principle, the blow molding forms mainly include extrusion blow molding, injection blow molding, injection extension blow molding (commonly known as “injection stretch blow”), multi-layer blow molding, sheet blow molding, etc. The equipment corresponding to blow molding of hollow products is usually called a plastic blow molding machine, and blow molding is only suitable for the production of thermoplastic products. The blow mold has a simple structure, and most of the materials used are carbon.

How do you manufacture plastic molds

There are many types and processing methods of plastic molds, the structures of plastic molding machines and plastic products are also different, so the types and structures of plastic molds are also diverse. With the rapid development of plastics industry, the continuous improvement of strength of ordinary plastics and engineering plastics, the application scope of plastic products continues to expand, and the consumption of plastic products continues to increase.

Plastic molds are tools for producing plastic products. It consists of several groups of parts with forming cavities in this combination. During injection molding, the mold is clamped on the injection molding machine, the molten plastic is injected into the molding cavity, and the mold is cooled in the cavity, then the upper and lower molds are separated, and the product is ejected from the cavity through the ejector system to leave the mold, and finally closed The mold performs the next injection molding, and the entire injection molding process is cycled.

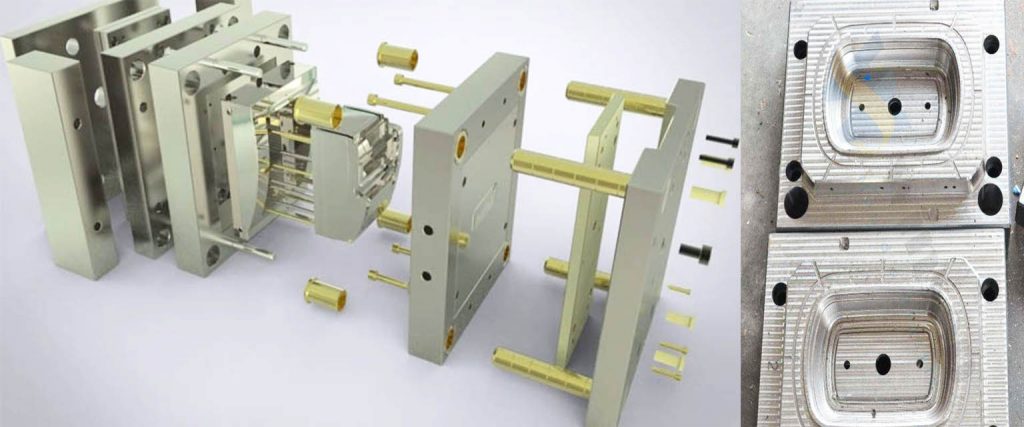

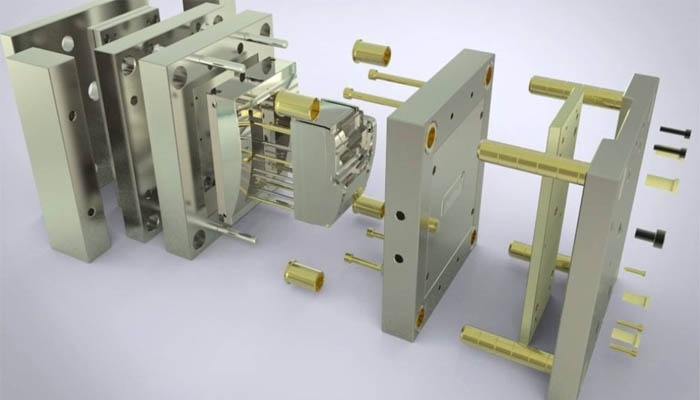

Plastic molds are generally composed of movable molds and fixed molds. Installed the movable mold on the movable template of injection molding machine, and installed the fixed mold on the fixed template of injection molding machine. During injection molding, the movable mold and the fixed mold are closed to form a casting system and a cavity. When the mold is opened, the movable mold and the fixed mold are separated, and the plastic products are taken out.

Although the structure of the mold may change continuously due to the variety and properties of the plastic, the shape and structure of the plastic product, the basic structure is the same for injection molding machine’s type. The mold is mainly composed of pouring system, temperature control system, forming parts and structural parts. Among them, the gating system and the molding parts are the parts that are in direct contact with the plastic, which vary with the plastic and the product, and are the most complex and diverse parts that require the highest processing finish and precision. The gating system is runner of part before the plastic enters the cavity from the nozzle, contains the main runner, cold material cavity, runner and gate, etc. Molded parts refer to various parts that make up the shape of a product, including movable molds, fixed molds and cavities, cores, molding rods, and exhaust ports.

Talk about mold and life

Mold is an essential process equipment for modern production. The mold’s level of design and manufacturing determines whether a country’s industrial production is competitive. The mold rapidly increases social wealth, and it is the money printing machine in industrial production. It can quickly and massively produce industrial products to meet people’s living needs and enrich our material life.

Common molds are injection molds and compression molds. A mold is a “copier” of a product, which can turn industrial raw materials into products with exactly the same size and shape. You can still remember that in the 1990s, all kinds of home appliances were very expensive. At that time, the average salary of ordinary people was between 800 to 900 to more than 1,000 a month, and color TVs, air conditioners, and refrigerators cost several thousand yuan each. It takes several months of salary to buy a home appliance. Now, it can be solved by spending about a month’s salary. Mobile phones and computers are also same. These all benefit from the rapid development of the mold industry.

Everyone’s impression of molds may come from the assembly lines of manufacturing companies such as electronics factories, injection molding factories, and automobile factories, because the manufacturing industry has attracted and solved the employment problem of most of the population in my country. Let’s talk about how mold affects our lives.

In the late 1970s, after the Third Plenary Session of the Eleventh Central Committee, my country decided to focus on economic construction, which opened the prelude to reform and opening up. At this time, the economic development of various capitalist countries and regions encountered bottlenecks and needed to upgrade their industries and develop new markets.

As a result, they have turned their attention to the vibrant China. At this time, China has abundant and cheap population resources and broad market prospects. Companies from the United States, Japan, and China’s Hong Kong and Taiwan regions have come to my country to invest and build factories one after another. While they bring capital, they also bring advanced management experience and technology. Among them, the introduction of mold technology has promoted my country’s industrial production, and my country’s private mold manufacturing enterprises are also blooming everywhere