What Makes Injection Molds Pricier? Injection molding is a widely used manufacturing process for producing a wide range of plastic parts and products. It’s known for its efficiency, precision, and scalability. However, it’s no secret that injection molds can be expensive. In this blog post, we’ll delve into the factors that contribute to the higher costs associated with injection molds. Understanding these reasons can help you make informed decisions when it comes to injection molding for your projects.

Table of Contents

ToggleWhat Makes Injection Molds Pricier

Numerous individuals responsible for overseeing plastic injection molding companies often express dissatisfaction with their profit margins. This dissatisfaction primarily stems from the considerable expenses associated with machinery and molds. Therefore, in this discussion, we will examine the factors contributing to the elevated cost of molds in the industry

1. Injection Mold Costs

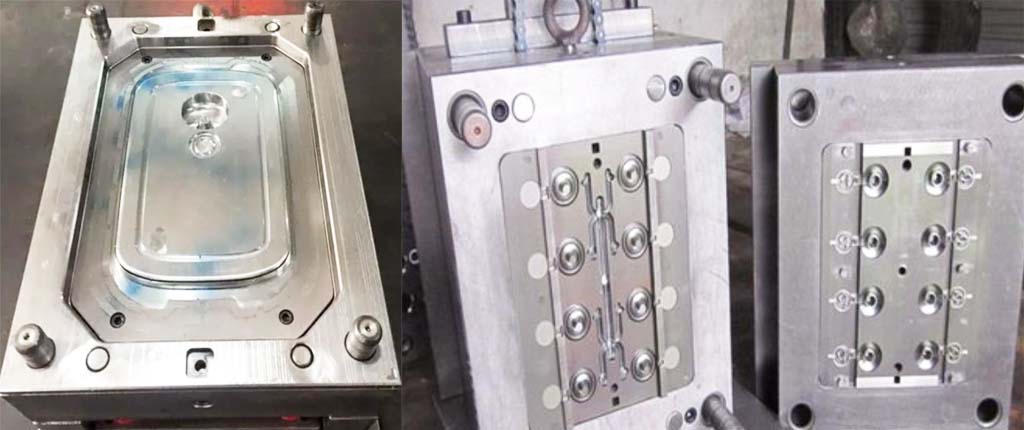

One of the primary factors that make injection molds pricey is the cost of tooling. Creating the molds themselves is a meticulous and time-consuming process that requires skilled engineers and precision machinery. The complexity and size of the mold, as well as the material used, all influence the overall tooling cost.

2. Injection Mold Material Selection

The choice of material for the injection mold is critical. High-quality and durable materials are essential to ensure the mold’s longevity and ability to withstand the stresses of high-speed injection molding. Premium materials, such as hardened steel or special alloys, tend to be more expensive but offer better performance and longevity.

3. Mold Size and Complexity

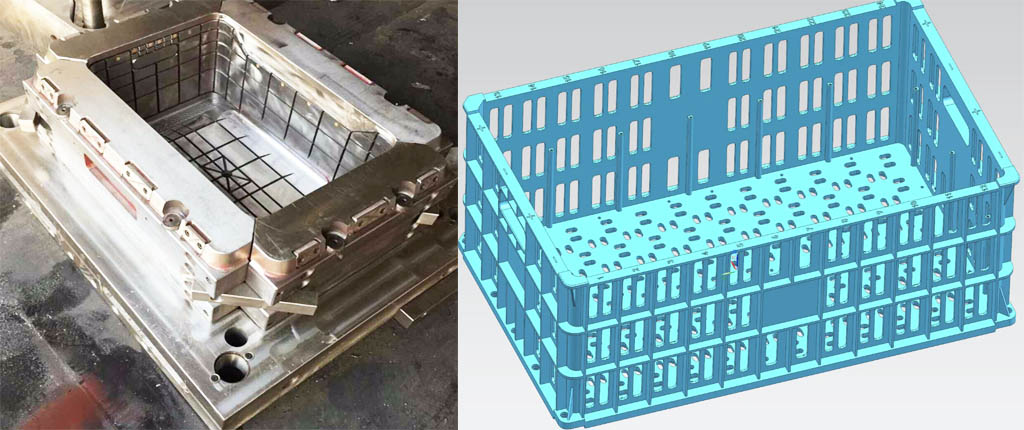

The size and complexity of the mold also significantly impact the cost. Larger and more intricate molds require more material, labor, and machining time. Molds with intricate details or multiple cavities also add to the complexity and cost.

Injection mold design demands a high level of precision, with a particular emphasis on the accuracy of the mold’s flow channel design. Inadequate design work can result in significant challenges if modifications are required after unsuccessful mold testing and prototyping, potentially necessitating the creation of entirely new molds.

4. Tolerances and Precision

Precision is a hallmark of injection molding. Tight tolerances and high precision in the molds result in consistent, high-quality parts. Achieving such precision demands advanced tooling and machining techniques, which, in turn, contribute to the overall cost.

5. Lead Time

The speed at which you need the mold can affect the cost. Rushing the mold-making process may lead to overtime work and expedited materials, which can increase expenses.

Injection mold production time is long,the extended production time for injection molds, as a result, leads to higher costs. Meticulous craftsmanship and precision drive the time-intensive nature of mold manufacturing

6. Maintenance and Repairs

Injection molds are subject to wear and tear over time. Proper maintenance and occasional repairs are necessary to ensure the mold’s ongoing performance. These maintenance costs should be factored into the overall price.

7. Volume of Production

The cost per part tends to decrease as the production volume increases. This is because the initial tooling investment is spread across a larger number of parts. Small production runs may result in a higher per-part cost due to the same tooling investment.

7. Diverse Manufacturing Techniques

The production of injection molds encompasses a wide array of manufacturing techniques. These intricate molds require a multitude of standard components, whose costs can significantly impact the overall expense. The meticulous design and construction of molds demand specialized skill sets and precise machining, all of which contribute to higher costs. Each mold’s unique intricacies are a testament to the precision required in the injection molding industry, underscoring the significance of investing in quality and the continuous pursuit of more efficient manufacturing processes.

7. Diverse Manufacturing Techniques

The production of injection molds encompasses a wide array of manufacturing techniques. These intricate molds require a multitude of standard components, whose costs can significantly impact the overall expense. The meticulous design and construction of molds demand specialized skill sets and precise machining, all of which contribute to higher costs. Each mold’s unique intricacies are a testament to the precision required in the injection molding industry, underscoring the significance of investing in quality and the continuous pursuit of more efficient manufacturing processes.

Sample-Based Mold Manufacturing Set Determination

At times, it may appear that even the simplest plastic components necessitate the use of two or even three sets of injection molds for production. As the final cost of these injection molds can add up to tens of thousands of yuan, this substantial price differential often leaves a significant psychological impact on customers.

Injection molds can indeed be pricey, but their quality and precision are critical for achieving consistent, high-quality plastic parts. Understanding the factors that contribute to the cost of injection molds allows you to make informed decisions about your manufacturing processes. Whether you are developing a new product or considering a production run, the investment in a high-quality injection mold can pay off in the long run by ensuring product reliability and minimizing defects.