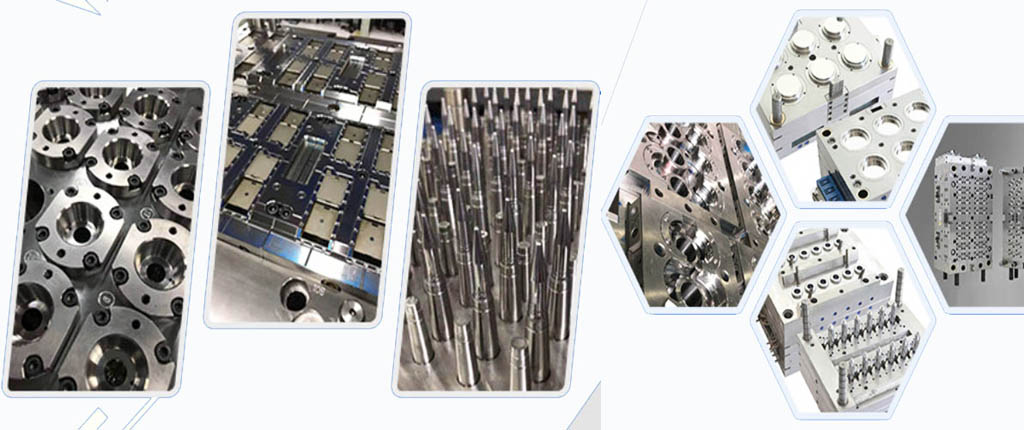

Why are molds so expensive! Mold quality and life are the decisive factors!

Mold quality grades are divided into 4 categories, not all molds are the same, you get what you pay for! What kind of price match what kind of mold quality.

Class 1 quality molds: must be capable of one million or more molds shots. The customer’s request must be processed with better materials and accessories.

Class 2 quality molds: about 500,000 molds shots are required. Good materials and accessories must be used, and the tolerance of the mold also has certain standards (meeting the dimensional accuracy requirements).

Class 3 quality molds: about 250,000 molds shots are required. This is a general mold requirement, and the production is also a medium production mold.

Grade 4 quality molds: about 10,000 molds shotsare required. This is a low-volume mold, and generally there are no special requirements.

Why is it so expensive to make a mold, tell you about the mold in detail !

Table of Contents

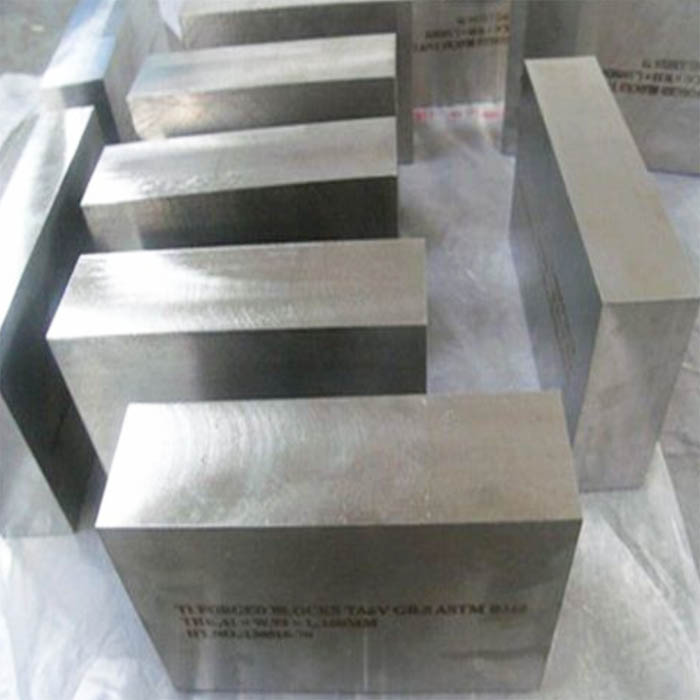

ToggleLook at the cost of the mold from the mold steel first!

(1). The primary and secondary quality mold materials usually use H131.2343 1.2344 LKM1.2343 LKM1..2344 1.2083 to add hard materials to 48-52HRC.

H13 1.2343 1.2344 about 65 pieces 1KG

The imported inner mold material LKM1.2343 LKM1.2344 is about 46 pieces of 1KG.

The most reliable mold material in China is Long Kee. Let me say more at this time. Whether it is buying Long Kee steel or mold embryos, they will definitely be able to do it if they agree to your requirements. Therefore, foreigners especially like to use Longji materials, and they are all designated. There are too many counterfeit goods, and some factories can make them at any price. This is the reason!

MOLOMAX HH is about 1000RMB/KG. This material is the most expensive. Imported beryllium copper has good thermal conductivity. The material density is very high. Care must be taken in design and processing.

Cost of the mold from the mold steel

(2). The third-grade mold steel powder is usually selected from Fenkl P20HH LKM738H LKM738MH H 1.2311, which are all pre-hardened materials, that is, they do not need to be hardened again, and the hardness is 28-34HR.

Fenk P20HH is about 46RMB/KG

LKM738H is about 38RMB/KG.

(3). The mold steel of the fourth-grade quality mold is usually made of domestic P20, which is about 18R, MB/KG.

30000RMB/set mold, what kind of steel would you choose?

1,000,000RMB/set mold, what kind of steel would you choose?

Look at the mold cost from the mold steel processing equipment

A high-speed machine Jintong is around 600,000RMB, a good 1-2 million.

A second-hand Sodick slow-moving wire costs tens of thousands of yuan.

Why do you say this, because the processing cost largely determines the quality of the mold!

Ordinary computer gong processing is 60RMB/hour, and high-speed machine is more than 1 times the price per hour.

The things cut by the medium wire are not bad, and the price of the Sodick slow wire cutting is twice that of the medium wire.

30000RMB/set of mold, what kind of equipment will you choose?

500,000RMB/set of molds, what kind of equipment will you choose to process?

It speaks for itself ha…

The main reason for the high mold production is the mold material processing equipment. In addition, the labor cost now accounts for a large proportion, and the salary of ordinary operators is 6-7K. Everyone who is a mold factory knows that the cost of artificial workshops is rising every year, and mold factories have moved to remote places.

Mold steel is widely used in industry, so the number of molds used can explain its important role, but there are still some poor quality mold steels on the market, so pay attention when purchasing molds.